55

User’s guide

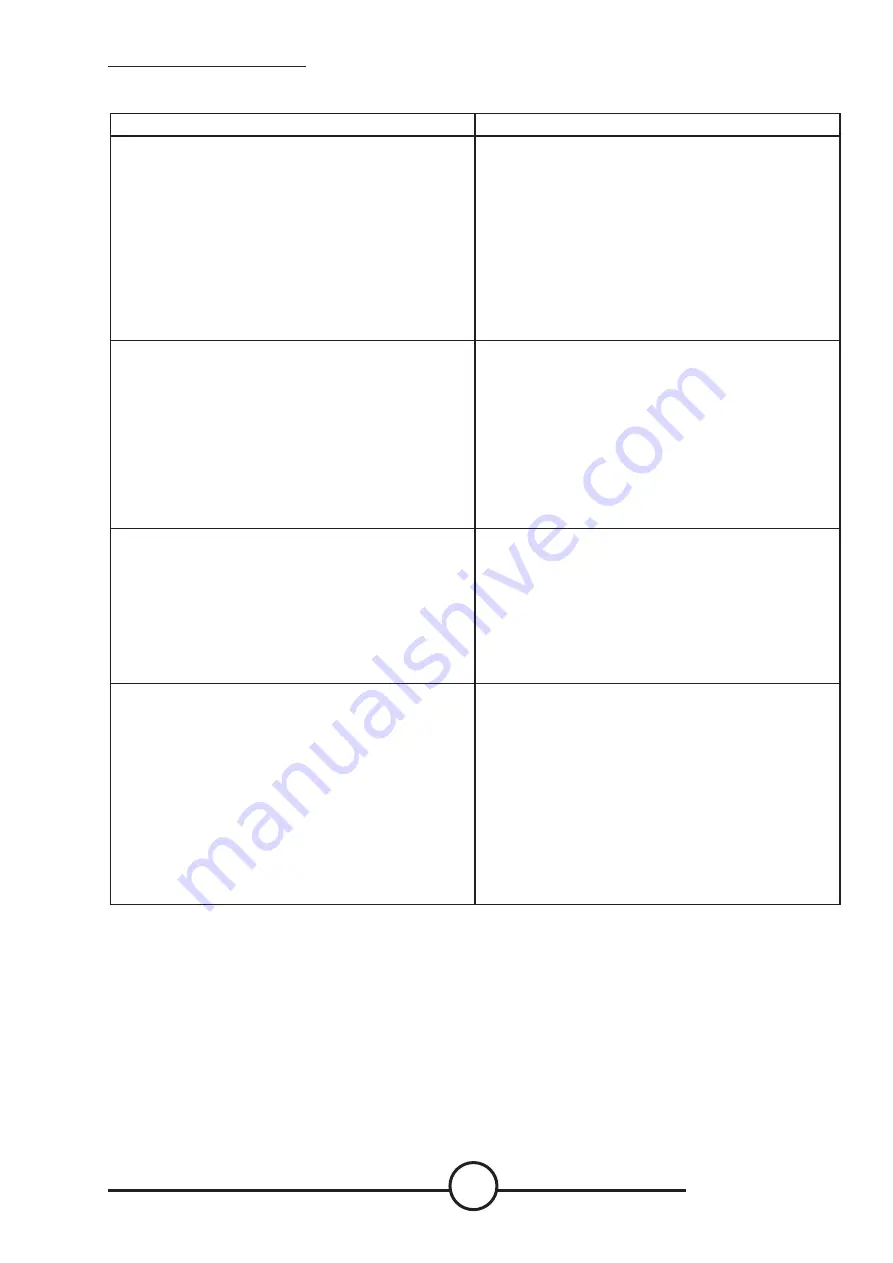

Problem

Solution

When the torch moves for the first cut, the torch tip

comes into contact with the material and stops the

machine.

Check that the Cut height is set to the correct value.

Check that the AVHC Auto/Manual mode is set to

Auto.

Check that the Sample voltage mode is set to ON.

At the place where the machine stops, check if the

machine crosses a previous cut or collides with

dross from a previous cut.

When the cut is executed, the torch retracts to a

sufficient distance from the material and the arc is

stretched or extinguished.

Check that the Cut height is set to the correct value.

Check that the AVHC Auto/Manual mode is set to

Auto.

Check that the Sample voltage mode is set to ON.

Check the connection of the arc voltage

measurement cable between the VFC box and the

plasma source.

The torch traces the part out but does not fire.

Check that the Dry Run/Active Run button shows

Active Run.

Check that OK to Move is enabled in the machine

control panel.

If the OK to Move option is disabled, check the errors

indicated on the plasma source.

The VMD screen displays “Accumove Controller Not

Connected” for more than 30 seconds.

Shut down the VMD software completely, and shut

down the Accumove controller for at least 30 sec-

onds.

Then power on the Accumove controller, wait anoth

-

er 30 seconds and open the VMD software.

Make sure that the red Ethernet cable is plugged into

the computer and the Accumove controller

Also verify that the red Ethernet cable is plugged into

the right or outermost port on Accumove 2 control

-

lers.

Software faults: (continued)