7-62

Service Manual

5062

Go Back

Previous

Next

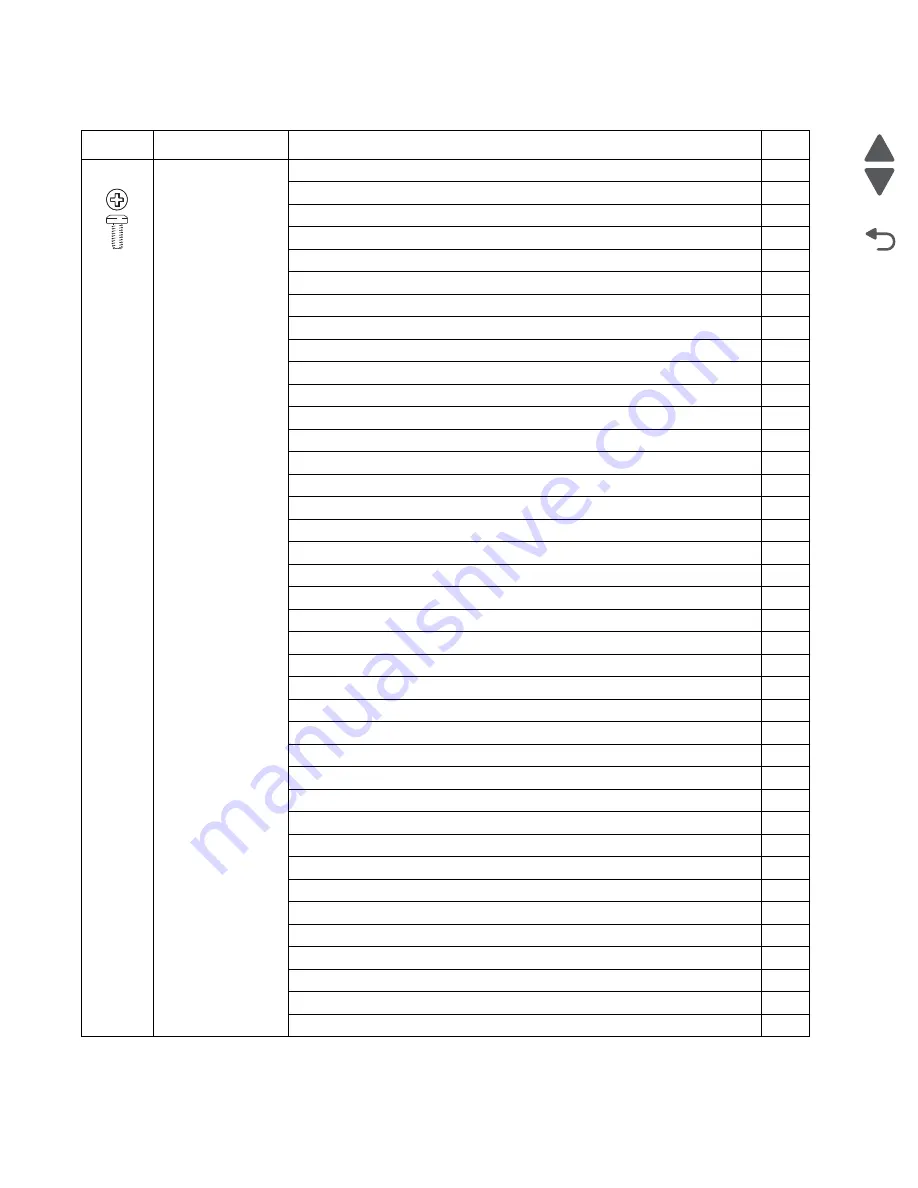

88A0323

Plastite

M3.5 x 8 mm PAN

550-sheet top metal cover to 550-sheet drawer

10

550-sheet bottom cover to 550-sheet drawer

8

550-sheet option deflector to 550-sheet drawer

1

550-sheet drive assembly to 550-sheet drawer

6

ACM bias spring to lower frame

1

Auto-connect harness to frame

7

Bottom plate to frame

7

Contact bracket to HVPS board

3

Cable retainers to frame

4

Cartridge blower assembly to front frame

1

Exit cooling fan duct to frame

3

Front access door beacon cover to waste toner left cover

2

Front access door pivot to top cover

3

Interlock housing assembly

3

ITU block assembly to frame

3

Left cover to top cover and left frame

2

Left frame cable cover

1

Logo panel to top cover

3

Lower left cover to frame

2

LVPS exit duct to frame

2

LVPS to frame

2

Media rails, left and right, to front lower frame

2

MPF breakaway assembly, front

3

MPF breakaway assembly, rear

2

MPF cable cover to lower frame

2

MPF connector cover to duplex assembly

3

MPF drive assembly to frame

3

Operator panel assembly to top cover

2

Operator panel display bracket to OP cover

4

Printhead access cover to top cover

2

Rear cover to top cover and frame

3

Rear upper cover to rear cover

1

Redrive assembly

3

Right cover

6

Speaker to top cover

1

Top cover to left cover and front frame

3

Tray beacon cable plate assembly

4

UICC card to operator panel cover

4

waste toner left cover to frame

8

Screw identification table (continued)

P/N

Screw type

Location

Qty

Summary of Contents for C792 Family

Page 14: ...xiv Service Manual 5062 Go Back Previous Next ...

Page 19: ...Notices and safety information xix 5062 Go Back Previous Next ...

Page 20: ...xx Service Manual 5062 Go Back Previous Next ...

Page 40: ...1 14 Service Manual 5062 Go Back Previous Next ...

Page 212: ...2 172 Service Manual 5062 Go Back Previous Next ...

Page 468: ...4 214 Service Manual 5062 Go Back Previous Next 7 Remove the motor from the bracket ...

Page 490: ...4 236 Service Manual 5062 Go Back Previous Next 4 Flex the sides to remove the roller frame ...

Page 592: ...4 338 Service Manual 5062 Go Back Previous Next ...

Page 594: ...5 2 Service Manual 5062 Go Back Previous Next Connectors System board ...

Page 610: ...5 18 Service Manual 5062 Go Back Previous Next 5 bin mailbox system card ...

Page 612: ...5 20 Service Manual 5062 Go Back Previous Next Finisher Stacker system card HTU system card ...

Page 616: ...6 4 Service Manual 5062 Go Back Previous Next ...

Page 622: ...7 6 Service Manual 5062 Go Back Previous Next Assembly 3 Front 1 2 4 5 6 7 8 3 3 3 3 ...

Page 624: ...7 8 Service Manual 5062 Go Back Previous Next Assembly 3 1 Front continued 1 2 4 5 1 1 1 3 ...

Page 626: ...7 10 Service Manual 5062 Go Back Previous Next Assembly 4 Left 1 2 4 5 6 8 7 3 ...

Page 628: ...7 12 Service Manual 5062 Go Back Previous Next Assembly 4 1 Left continued 1 2 3 4 ...

Page 630: ...7 14 Service Manual 5062 Go Back Previous Next Assembly 5 Rear 1 2 3 6 11 8 9 12 4 7 5 13 10 ...

Page 632: ...7 16 Service Manual 5062 Go Back Previous Next Assembly 6 Optional 550 sheet tray 2 3 1 ...

Page 644: ...7 28 Service Manual 5062 Go Back Previous Next Assembly 11 Finisher stapler assembly 1 2 ...

Page 648: ...7 32 Service Manual 5062 Go Back Previous Next Assembly 13 5 bin mailbox assembly complete 1 ...

Page 654: ...7 38 Service Manual 5062 Go Back Previous Next Assembly 16 HTU complete 1 ...

Page 662: ...7 46 Service Manual 5062 Go Back Previous Next Assembly 20 HTU with hole punch complete 1 ...

Page 682: ...A 2 Service Manual 5062 Go Back Previous Next Print Quality Pages Page 1 total of five ...

Page 684: ...A 4 Service Manual 5062 Go Back Previous Next Print Quality Pages Page 3 total of five ...

Page 704: ...I 14 Service Manual 5062 Go Back Previous Next ...