2-10

Service Manual

5062

Go Back

Previous

Next

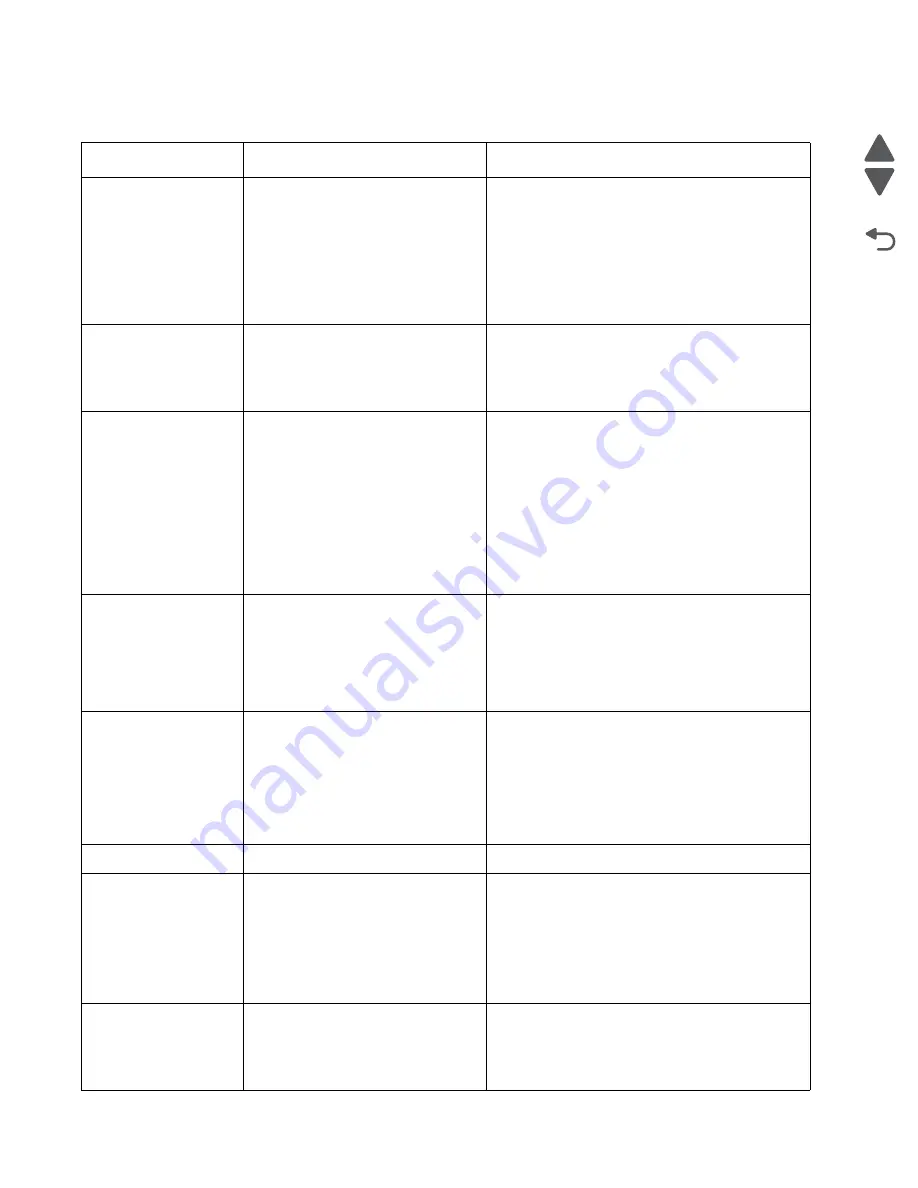

Additional checks—202–203 paper jams

Error code

Description

Action

202.01

Exit sensor is made when printer tries

to print from an idle state.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Damaged fuser autoconnect

• Faulty fuser

• Faulty system board

1. Check for anything in the paper path that might

cause the paper to jam.

2. The fuser exit sensor may not be functioning

properly. Go to

“121.xx—Fuser error service

check” on page 2-70

.

202.02

Exit sensor is made early.

Possible causes:

• Incorrect paper settings

• Defective exit sensor

1. Check for anything in the paper path that might

cause the paper to jam.

2. If clearing the jam does not solve the problem,

go to

“121.xx—Fuser error service check” on

page 2-70

.

202.03

Exit sensor is never made.

Possible causes:

• Improper paper loading

• Paper wrapped in fuser

• Damaged paper exit sensor or

paper exit sensor flag

• Damaged fuser autoconnect

• Faulty fuser DC cable connection

• Faulty fuser

• Faulty system board

1. Check for anything in the paper path that might

cause the paper to jam.

2. The fuser exit sensor may not be functioning

properly. Go to

“121.xx—Fuser error service

check” on page 2-70

.

202.04

Exit sensor broke early.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Faulty fuser

• Faulty system board

The fuser exit sensor may not be functioning

properly. Go to

“121.xx—Fuser error service

check” on page 2-70

.

202.05,

202.07

Exit sensor never broke.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Faulty fuser

• Faulty system board

• Faulty output bin flag

1. Check exit sensor flag on fuser for proper

operation. Be sure the paper is not hanging on

the flag.

2. The fuser exit sensor may not be functioning

properly. Go to

“121.xx—Fuser error service

check” on page 2-70

.

202.08

Exit sensor is never made.

See

“202.03” on page 2-10

.

202.31

Bin-full sensor active when printing

started.

Possible causes:

• Paper jam leaving paper over the

sensor

• Damaged bin-full sensor

• Faulty system board.

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Flex the media, and stack it flat in the tray.

4. Properly set the paper guides in the paper tray.

5. If the problem persists, go to

“Pick arm stuck

down service check” on page 2-164

.

202.32

Binfull sensor is made early.

Possible causes:

• Incorrect paper settings

• Defective bin-full sensor

1. Check for anything in the paper path that might

cause the paper to jam.

2. If clearing the jam does not solve the problem,

go to

“202.32—Paper Jam error service

check” on page 2-107

.

Summary of Contents for C792 Family

Page 14: ...xiv Service Manual 5062 Go Back Previous Next ...

Page 19: ...Notices and safety information xix 5062 Go Back Previous Next ...

Page 20: ...xx Service Manual 5062 Go Back Previous Next ...

Page 40: ...1 14 Service Manual 5062 Go Back Previous Next ...

Page 212: ...2 172 Service Manual 5062 Go Back Previous Next ...

Page 468: ...4 214 Service Manual 5062 Go Back Previous Next 7 Remove the motor from the bracket ...

Page 490: ...4 236 Service Manual 5062 Go Back Previous Next 4 Flex the sides to remove the roller frame ...

Page 592: ...4 338 Service Manual 5062 Go Back Previous Next ...

Page 594: ...5 2 Service Manual 5062 Go Back Previous Next Connectors System board ...

Page 610: ...5 18 Service Manual 5062 Go Back Previous Next 5 bin mailbox system card ...

Page 612: ...5 20 Service Manual 5062 Go Back Previous Next Finisher Stacker system card HTU system card ...

Page 616: ...6 4 Service Manual 5062 Go Back Previous Next ...

Page 622: ...7 6 Service Manual 5062 Go Back Previous Next Assembly 3 Front 1 2 4 5 6 7 8 3 3 3 3 ...

Page 624: ...7 8 Service Manual 5062 Go Back Previous Next Assembly 3 1 Front continued 1 2 4 5 1 1 1 3 ...

Page 626: ...7 10 Service Manual 5062 Go Back Previous Next Assembly 4 Left 1 2 4 5 6 8 7 3 ...

Page 628: ...7 12 Service Manual 5062 Go Back Previous Next Assembly 4 1 Left continued 1 2 3 4 ...

Page 630: ...7 14 Service Manual 5062 Go Back Previous Next Assembly 5 Rear 1 2 3 6 11 8 9 12 4 7 5 13 10 ...

Page 632: ...7 16 Service Manual 5062 Go Back Previous Next Assembly 6 Optional 550 sheet tray 2 3 1 ...

Page 644: ...7 28 Service Manual 5062 Go Back Previous Next Assembly 11 Finisher stapler assembly 1 2 ...

Page 648: ...7 32 Service Manual 5062 Go Back Previous Next Assembly 13 5 bin mailbox assembly complete 1 ...

Page 654: ...7 38 Service Manual 5062 Go Back Previous Next Assembly 16 HTU complete 1 ...

Page 662: ...7 46 Service Manual 5062 Go Back Previous Next Assembly 20 HTU with hole punch complete 1 ...

Page 682: ...A 2 Service Manual 5062 Go Back Previous Next Print Quality Pages Page 1 total of five ...

Page 684: ...A 4 Service Manual 5062 Go Back Previous Next Print Quality Pages Page 3 total of five ...

Page 704: ...I 14 Service Manual 5062 Go Back Previous Next ...