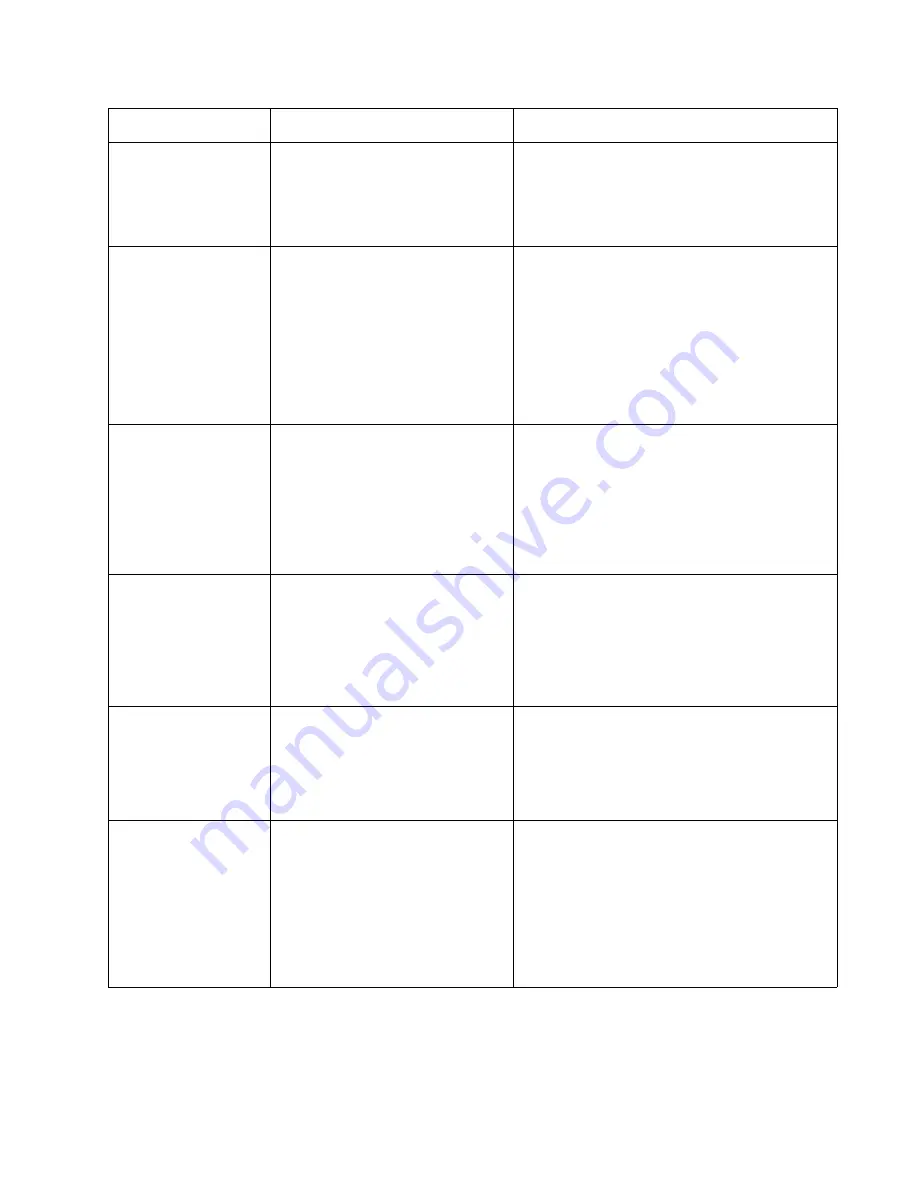

Diagnostic information

2-23

5026

230.21

Duplex motor stalled.

Possible causes:

• Obstructed duplex path

• Defective duplex motor

• Faulty system board

• Check for anything in the duplex paper path that

might cause the paper to jam. This includes the

paper guides in tray 1.

• If clearing a paper jam does not fix the problem,

go to

“146.xx, 148.xx—Motor (MPF/duplex)

error service check” on page 2-48

.

241.03

While feeding from tray 1, the input

sensor does not break.

Possible causes:

• Incorrect media setting

• Incorrect paper loading

• Incorrect media restraint setting

• Paper pick mechanism failure

• Transport belt motor failure

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Ensure proper media is set for the type of paper

used.

3. Fan media, and stack it flat in the tray or

multipurpose feeder.

4. Properly set media restraints in paper tray.

5. Check the pick arm rolls (tires) and replace if

worn.

If the problem persists, go to

“200.11, 250.03—

Paper Jam error service check” on page 2-59

.

241.05

While feeding from tray 1, the input

sensor is never made.

Possible causes:

• Incorrect paper loading

• Incorrect media restraint setting

• Pick art rolls (tires) failure

• Paper pick mechanism failure

• System board failure

1. Remove all media present in the paper path.

2. Fan media, and stack it flat in the tray or

multipurpose feeder.

3. Properly set media restraints in paper tray.

4. Check the pick arm rolls (tires) and replace if

worn.

If the problem persists, go to

“140.xx, 920.02—

Autocomp (tray 1) motor error service check”

on page 2-43

.

241.21

Tray 1 motor stalled.

Possible causes:

• Incorrect paper loading

• Paper pick mechanism failure

• System board failure

1. Remove all media present in the paper path.

2. Ensure proper media is set for the type of paper

used.

3. Fan media, and stack it flat in the tray or

multipurpose feeder.

If the previous actions do not fix the problem, go to

“140.xx, 920.02—Autocomp (tray 1) motor error

service check” on page 2-43

.

242.02

Tray 2 pass thru sensor made at

POR.

Possible causes:

• Paper jam leaving paper over

sensor

• Defective pass thru sensor

• Check for anything in the paper path that might

cause the paper to jam.

• If the error persists, go to

“242.02—Paper Jam

service check” on page 2-68

.

242.03

Pick timeout from tray 2 exceeded

without a tray 2 sensor break.

Possible causes:

• Incorrect media setting

• Incorrect paper loading

• Incorrect media restraint setting

• Tray 2 assembly failure

• Aligner failure

• Transport belt module failure

1. Remove all media present in the paper path.

2. Ensure proper media is set for the type of paper

used in tray 2.

3. Fan media, and stack flat in tray 2.

4. Properly set media restraints in tray 2.

If the paper jam message persists, go to

“242.03,

242.11—Paper Jam service check” on

page 2-69

.

Error code

Description

Action

Summary of Contents for C734 series

Page 13: ...Notices and safety information xiii 5026 ...

Page 14: ...xiv Service Manual 5026 ...

Page 170: ...2 136 Service Manual 5026 ...

Page 288: ...4 72 Service Manual 5026 12 Remove the seven screws M securing the EP drive ...

Page 339: ...Repair information 4 123 5026 13 Remove the three printhead mounting screws D ...

Page 395: ...Connector locations 5 1 5026 5 Connector locations Locations ...

Page 408: ...7 2 Service Manual 5026 Assembly 1 Covers ...

Page 410: ...7 4 Service Manual 5026 Assembly 2 Front ...

Page 412: ...7 6 Service Manual 5026 Assembly 3 Right 1 2 3 4 5 6 ...

Page 414: ...7 8 Service Manual 5026 Assembly 4 Rear ...

Page 424: ...7 18 Service Manual 5026 Assembly 11 Options and features ...

Page 426: ...7 20 Service Manual 5026 ...

Page 436: ...I 10 Service Manual 5026 ...