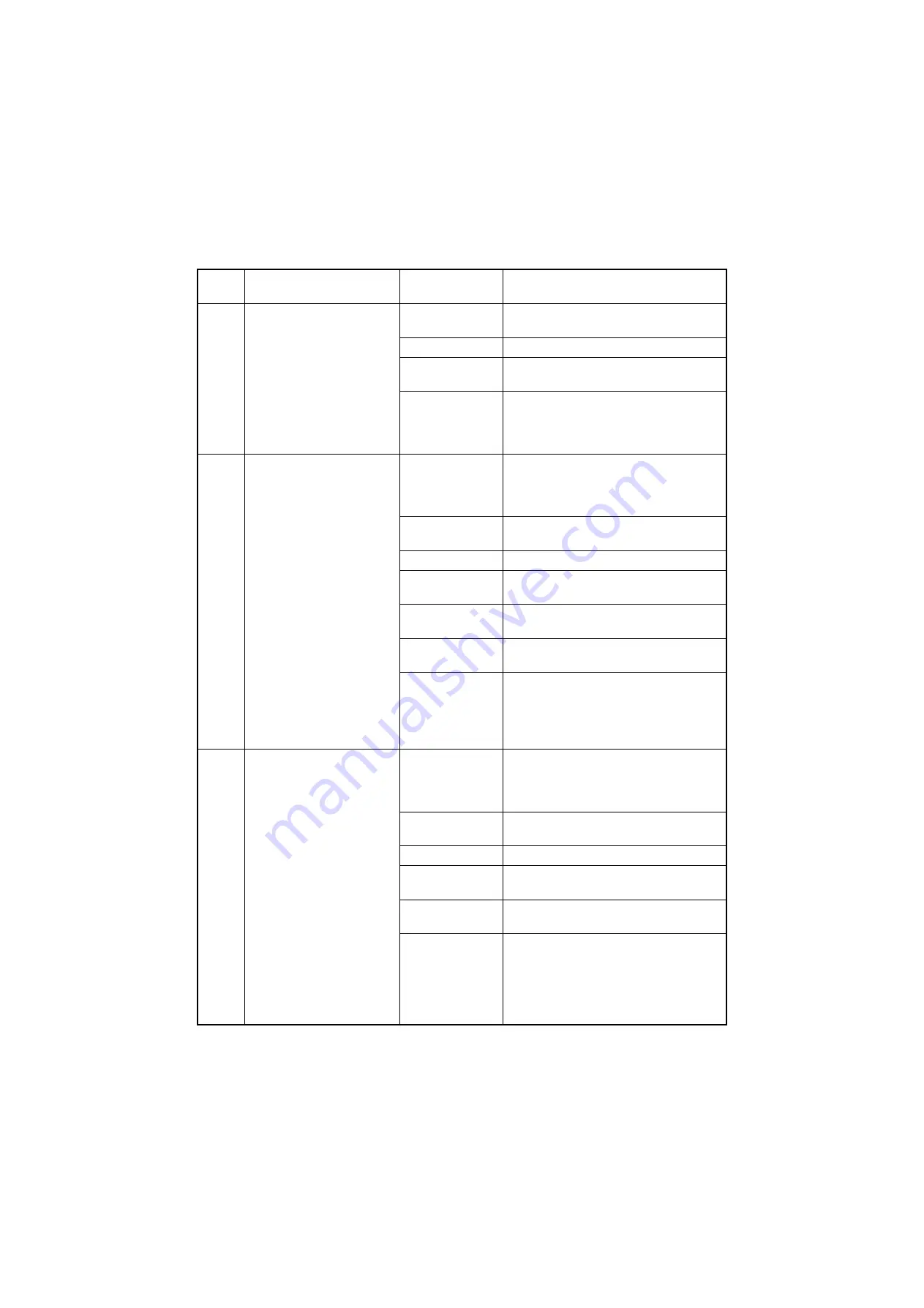

2LL/2LJ/2LH-1

1-4-37

6020

Abnormally high fuser

thermistor 1 temperature

Fuser thermistor 1 detects a

temperature higher than

240

C/464

F for 1 s.

Deformed connec-

tor pin.

See page 1-4-40.

Defective triac.

See page 1-4-40.

Shorted fuser

thermistor 1.

Replace the fuser unit (see page 1-5-39).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-47).

6030

Broken fuser thermistor 1

wire

A temperature of less than

30°C/86

F was observed at

the fuser thermistor 2 when

the temperature at the fuser

thermistor 1 is greater than

70°C/158

F during warming

up.

Fuser thermistor 1 detects a

temperature lower than 50

C/

122

F for 15 s during warming

up.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

Fuser unit and engine PWB (YC26)

Deformed connec-

tor pin.

See page 1-4-40.

Defective triac.

See page 1-4-40.

Broken fuser

thermistor 1 wire.

Replace the fuser unit (see page 1-5-39).

Fuser thermostat

triggered.

Replace the fuser unit (see page 1-5-39).

Defective fuser

heater.

Replace the fuser unit (see page 1-5-39).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-47).

6040

Fuser heater error

The state of the CPU port

PH1 at H level for 1 [sec] is

determined to be a loose con-

nector in any operation state.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

Fuser unit and engine PWB (YC26)

Deformed connec-

tor pin.

See page 1-4-40.

Defective triac.

See page 1-4-40.

Broken fuser

thermistor 1 wire.

Replace the fuser unit (see page 1-5-39).

Defective fuser

heater.

Replace the fuser unit (see page 1-5-39).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-47).

Code

Contents

Causes

Check procedures/

corrective measures

Summary of Contents for TASKalfa 3500i

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 24: ...2LL 2LJ 2LH 1 1 10 This page is intentionally left blank ...

Page 124: ...2LL 2LJ 2LH 1 2 100 ...

Page 304: ...2LL 2LJ 2LH 1 3 180 This page is intentionally left blank ...

Page 397: ...2LL 2LJ 2LH 1 4 93 This page is intentionally left blank ...

Page 508: ...2LL 2LJ 2LH 2 1 26 This page is intentionally left blank ...

Page 515: ...2LL 2LJ 2LH 2 2 7 45 ppm model 55 ppm model only ...

Page 623: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR DOCUMENT PROCESSOR ...

Page 658: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 671: ...INSTALLATION GUIDE FOR LARGE CAPACITY FEEDER ...

Page 686: ...INSTALLATION GUIDE FOR SIDE DECK ...

Page 711: ...INSTALLATION GUIDE FOR 1000 SHEETS FINISHER ...

Page 724: ...INSTALLATION GUIDE FOR 4000 SHEETS FINISHER ...

Page 740: ...INSTALLATION GUIDE FOR FINISHER ATTACHMENT KIT ...

Page 754: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 771: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 779: ...INSTALLATION GUIDE FOR PUNCH UNIT ...

Page 799: ...INSTALLATION GUIDE FOR INNER JOB SEPARATOR ...

Page 800: ...1 2 3 A B ...

Page 801: ...7 8 4 5 6 ...

Page 802: ...11 9 10 ...

Page 803: ...A 1 2 3 3 2 14 15 12 13 16 ...

Page 804: ...B 19 17 18 ...

Page 805: ...21 22 20 ...

Page 806: ...26 27 23 24 28 25 ...

Page 807: ...30 29 ...

Page 808: ...INSTALLATION GUIDE FOR RIGHT JOB SEPARATOR ...

Page 809: ...5 1 2 3 4 5 7 7 6 A B C A B ...

Page 810: ...9 10 11 12 13 14 7 8 Ԙ ԙ Ԙ ԙ C ...

Page 811: ...INSTALLATION GUIDE FOR FAX System ...

Page 836: ...2011 ...

Page 837: ...2011 ...