2BC/D-1

1-6-18

(6-4) Adjusting the margins for printing

Make the following adjustment if the margins are not correct.

Caution

Check the copy image after the adjustment. If the margins are still incorrect, perform the above adjustments in

maintenance mode.

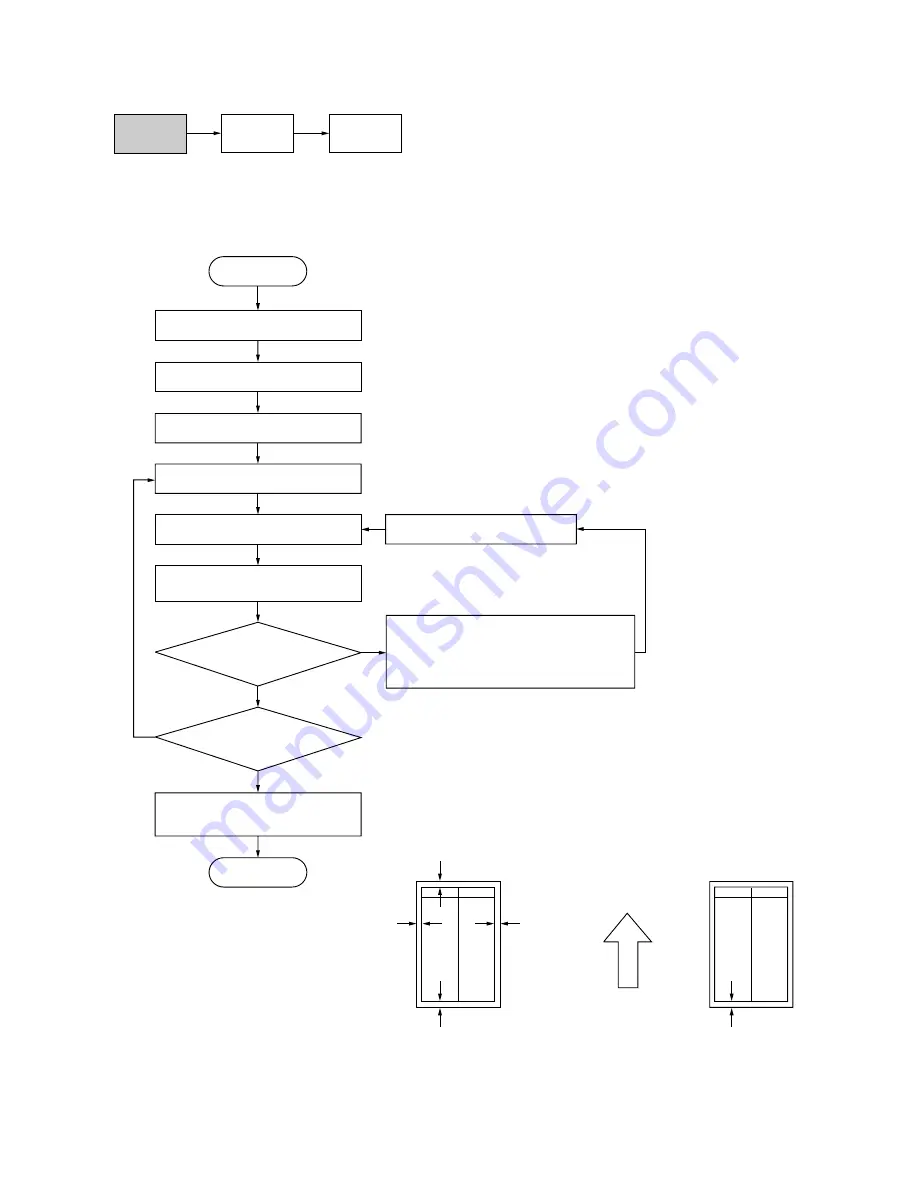

Procedure

Figure 1-6-35

U402

U403

(P. 1-6-38)

U404

(P. 1-6-72)

Yes

No

Start

Enter maintenance mode.

Enter “402” using the numeric keys.

Press the start key.

Press the start key to output a test

pattern using A3/11"

×

17" paper.

Press the start key.

The new setting is stored.

Setting range (initial setting)

LEAD: 0 – +10.0 (

3.5

)

A: –5.0 – +10.0 (

2.5

)

C: –5.0 – +10.0 (

2.5

)

TRAIL: –5.0 – +10.0 (

6.4

)

TRAIL (DUP): –5.0 – +10.0 (

6.4

)

Changing the value by 1 moves the

margin by 0.1 mm for all.

Select the items to be adjusted.

Are the margins correct?

Change the setting.

Increasing the value using the cursor up

key makes the margin winder.

Decreasing the value using the cursor

down key makes the margin narrower.

Press the interrupt key.

LEAD: Printer leading edge margin

A: Printer left margin

C: Printer right margin

TRAIL: Printer trailing edge margin

TRAIL (DUP): Printer trailing edge margin for

duplex copying (second face)

Yes

No

Press the stop/clear key to

exit maintenance mode.

End

Proceed to

another mode?

Ejection direction

(reference)

Printer trailing edge margin

for duplex copying

(6

±

2.5 mm)

Printer leading edge margin

(6

±

2.5 mm)

Printer

left margin

(6

±

2.0 mm)

Printer

right margin

(6

±

2.0 mm)

Printer trailing edge margin

(6

±

2.5 mm)

Duplex copy mode

(second face, A3/11"

×

17")

Normal copy mode

(A3/11"

×

17")

Summary of Contents for KM-4530

Page 1: ...SERVICE MANUAL Published in Apr 02 2BC70761 Revision 1 KM 4530 5530...

Page 76: ...2BC D 1 1 4 13 This page is intentionally left blank...

Page 100: ...1 4 35 2BC D 1 This page is intentionally left blank...

Page 142: ...2BC D 1 This page is intentionally left blank...

Page 173: ...2BC D 1 This page is intentionally left blank...

Page 187: ...2BC D 1 1 5 42 This page is intentionally left blank...

Page 374: ...2BC D 1 2 4 16 This page is intentionally left blank...

Page 380: ...2BC D 1 2 4 22 This page is intentionally left blank...