Removing the Tool Holder from the Cutter Head

KVAL Operation Manual

5-14

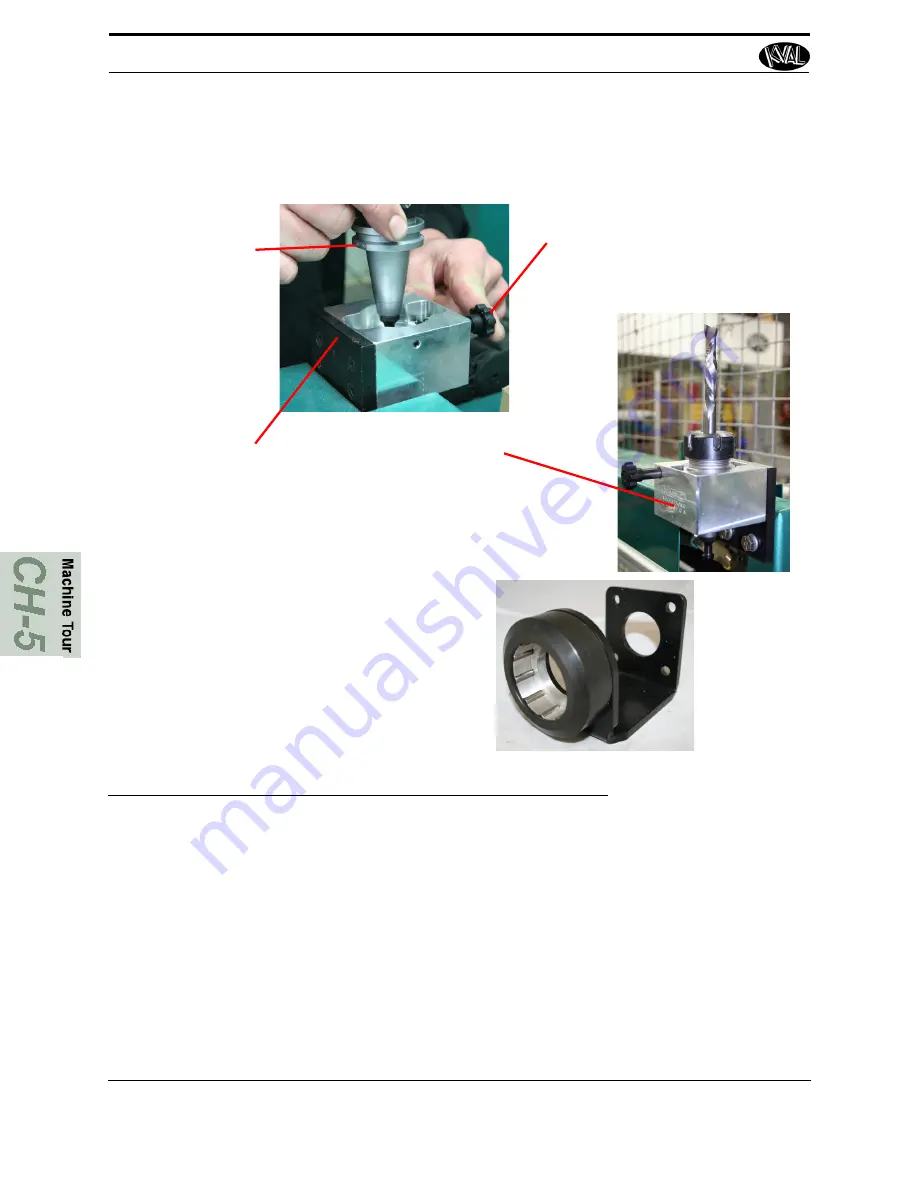

How to Change a Tool Bit

1.

Set the tool in the Tool-Change Tightening Fixture.

Quick Release will

snap into place after

collet is inserted into

base

Tool-Change Fixture

V-Flange:

Flat Edges are

Orientated in Line

with Knob

Fully Assembled Tool

Locked in to Place

For

HSK Tool Holders

, follow the same steps in

this section, except use this fixture.

Note:

There is no quick release on this model. The

collet nut will snap into place automatically when

aligned correctly.

FIGURE 5-3.

Using Tool Change Fixture

2.

Use the collet wrench to loosen the collet nut, freeing the bit.

3.

Remove the old bit, clean the collet with compressed air.

Note:

Never use a torque wrench to loosen hardware. It could damage the wrench.

4.

Check collet for bluing or damage

Note:

Bluing is a condition that occurs when the collet is overheated. The overheating

causes the metal to turn blue. If bluing occurs, the collet must be scrapped.

5.

Reassemble the tool. When assembling, bottom out tool and back up about 1/4'' to

ensure the correct distance.

Tool should not stay bottomed out.

Note:

The collet should snap into place into the collet nut

Summary of Contents for DL-NCD

Page 10: ...KVAL DL NCD Operation Manual Table of Contents ...

Page 28: ...How to Download the Service Application KVAL Operation Manual 1 18 ...

Page 30: ...Safety Sign Off Sheet KVAL Operation Manual 1 20 ...

Page 62: ...About the LiteCutout Feature Detail KVAL Operation Manual 2 32 ...

Page 94: ...Appendix About Backing up the Data KVAL Operation Manual 3 32 ...

Page 118: ...Appendix Servo Motor Drive Assembly Locations KVAL Operation Manual 4 24 ...

Page 139: ...About the Electrical Panels KVAL Operation Manual 5 21 I ...

Page 142: ......

Page 143: ......