Maintenance

140

Adjusting the crawler tension

Tightening the crawlers

!

Position the grease gun (2) on the grease nipple (1).

!

Pump the grease gun until the specified crawler tension is ob-

tained.

Loosening the crawlers

!

Cautiously unscrew the pressure valve and loosen the crawler.

!

Screw in the pressure valve and torque to 100-110 Nm.

!

Tighten the crawler.

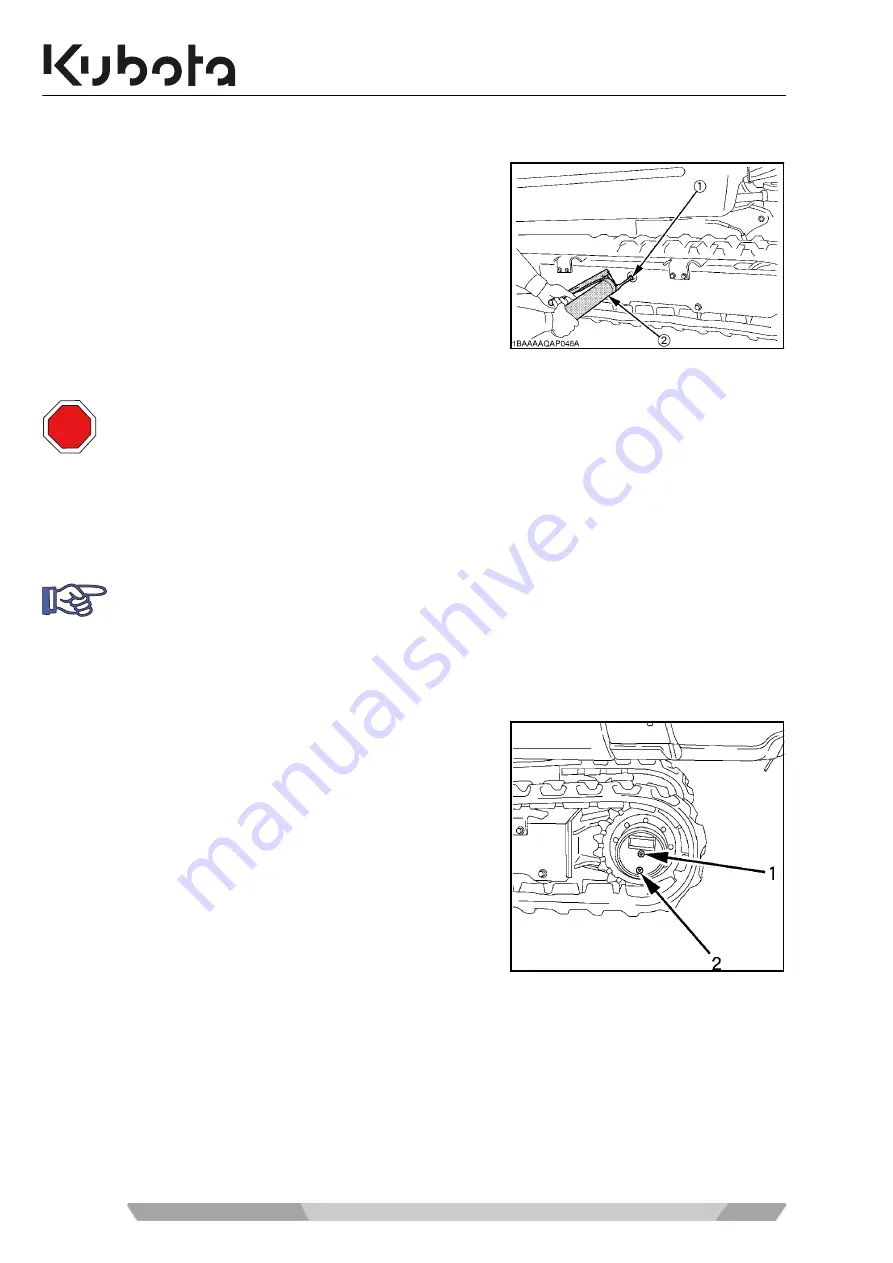

Replace the drive unit oil

!

Park the excavator on level ground so that the drain plug (figure below, position 2) is positioned at the bottom.

!

Place a catch tray with a minimum capacity of 2 L under the drain plug.

!

Remove the drain plug and let the oil drain completely. Install

the drain plug with a new sealing ring on it.

!

Unscrew the filler plug (1).

!

Fill oil as specified in the "Recommended lubricants" section

(page 146). The oil level is the lower edge of the thread.

Capacities:

0.33 L

!

Provide filler plug with new oil ring and screw in.

!

Perform the same service on the second drive unit.

Grease could squirt out from the cylinder opening.

Only change the oil when the drive unit is warm to the hand; if not, drive the excavator warm.

STOP