Maintenance

137

Lubrication

The following describes all lubricating tasks which should be performed with the superstructure.

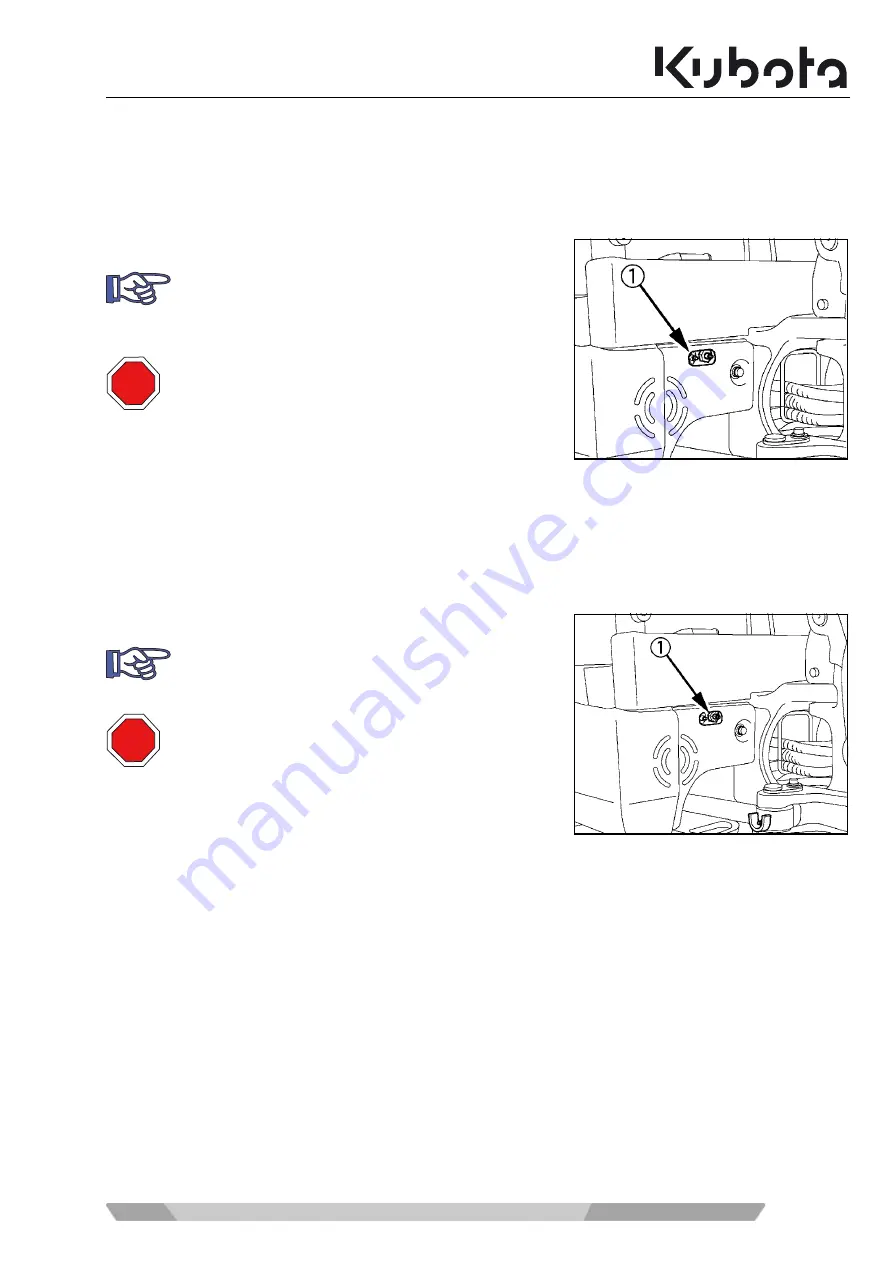

Greasing the swivel gear

!

Fill grease through the grease nipple (1) with a grease gun.

!

Operate the excavator and swivel the swivel frame by 90° several times. After greasing, swivel the swivel

frame 360° several times to distribute the grease evenly.

Greasing the pitch bearing

!

Fill grease through the grease nipple (1) with a grease gun.

!

Operate the excavator and swivel the swivel frame by 90° several times. After greasing, swivel the swivel

frame 360° several times to distribute the grease evenly.

Grease at each 90° position of the swivel gear. Fill a to-

tal of approx. 50 g of grease (approx. 20 shots with the

grease gun). Refer to the "Recommended lubricants"

section (page 146).

When moving the swivel frame, make sure no person

or material is in the swivel area. Turn the starter switch

to the STOP position and remove the key before the

next greasing procedure.

Grease at each 90° position of the pitch bearing. Using

the grease gun, apply 5 shots at every position. Refer

to the "Recommended lubricants" section (page 146).

When moving the swivel frame, make sure no person

or material is in the swivel area. Turn the starter switch

to the STOP position and remove the key before the

next greasing procedure.

STOP

STOP