7 Servicing/Maintenance

84 of 116

CHTRa

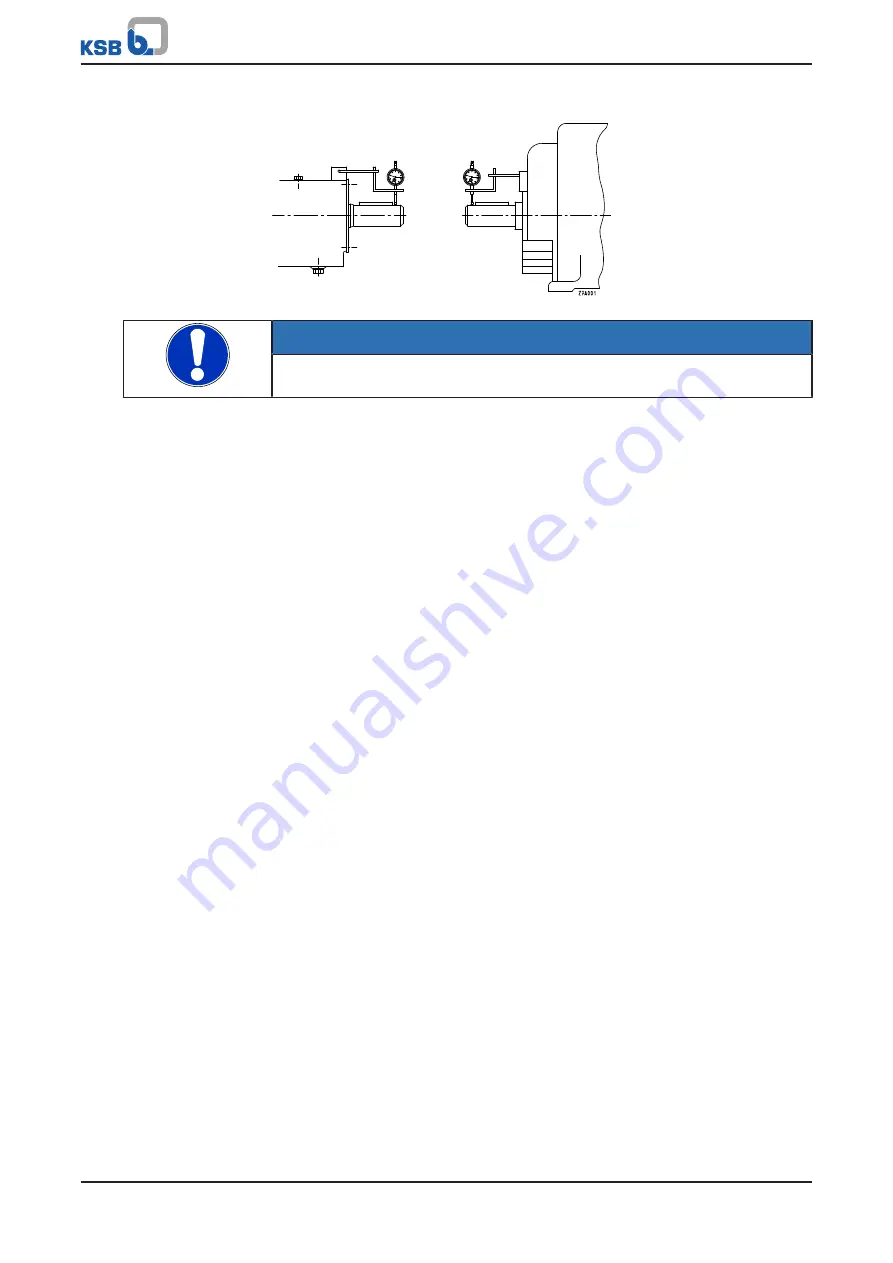

7.3.4.3 Checking the shaft ends for run-out

Fig. 36:

Checking the shaft ends for run-out

NOTE

Observe the marking between coupling hub and shaft. (

1. Permissible tolerance at the pump shaft ≤ 0.03 mm. If this value is exceeded,

contact KSB.

2. Permissible tolerance of the motor shaft, see the data provided by the

manufacturer.

7.3.5 Removing the pump from the system (if necessary)

7.3.5.1 Dismantling the piping and instruments

1. Have a container on hand for both the fluid handled and the supplies and, if

required, place it underneath the connections of the pipes to be dismantled.

2. Secure inlet and discharge lines.

3. Undo the connections between discharge nozzle and discharge line and

between suction nozzle and suction line.

4. Dismantle the minimum flow valve, if installed.

5. Disconnect the tapping pipe, if applicable.

6. Detach and dismantle any auxiliary lines such as balancing liquid, circulation,

cooling liquid and oil pipes or measuring lines as far as necessary.

7. Dismantle the measuring instruments as far as necessary, and store them

appropriately.

8. If required, dismantle the shaft seal cooler including support.

9. Dispose of the fluid handled and the supplies in compliance with environmental

standards.

10. Close the openings of all dismantled pipes.