DEVICE DESCRIPTION

2

13

WATERFLUX 3070

www.krohne.com

06/2016 - 4004999701 - MA WATERFLUX 3070 - R01 en

2.2 Device description

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

The following versions are available:

•

Compact version (the signal converter is mounted directly on the measuring sensor) in

polycarbonate (IP68) housing

•

Remote version (measuring sensor with a stainless steelconnection box and a signal

converter in a remote, polycarbonate housing)

Both versions are available with an optional integrated P&T sensor.

INFORMATION!

Product specific information and extensive product specification is available using PICK, the

Product Information Center KROHNE web-tool.

PICK can be found via the service menu button on the KROHNE.com website.

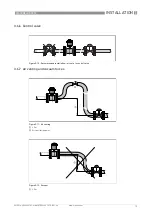

Figure 2-2: Device versions

1

Compact version

2

Remote version