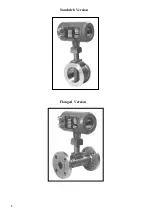

VFM 5090(I) may be supplied with an optional

pressure sensor. This sensor is typically a strain gauge

type and located in the primary assembly as shown in

the figure below. Thus the sensor also provides an

accurate measurement of pressure

of the process fluid.

Flowmeter will continuously measure medium

pressure -

·

·

·

To display the medium pressure value

To provide an on-line P&T compensation along

with T sensor for mass and normalized volumetric

flow computation.

To monitor whether the medium pressure is within

the user specified operating pressure limits.

To determine the pressure of the medium (e.g. to feed

the pressure value in VFM for an off-line P&T

compensation for mass or normalized flow

computations), suitable measuring point must be

provided near the flowmeter.

Location upstream of flowmeter

Min. distance : 20*DN (DN = meter size)

Location downstream of flowmeter

Min. distance : 5*DN (DN = meter size)

Allowance must be made for the pressure drop in the

flowmeter as correction value for operating conditions

prevailing upstream of the flowmeter.

3. Electrical

connection

3.1

Installation location and cable diameter

Location

·

·

·

·

·

·

·

·

·

·

·

Do not expose the compact flowmeter to direct

sunlight. Install a sunshade if necessary.

Do not expose to intense vibration. If necessary

support the pipeline to the left & right of the flow

meter.

The rotating design of the housing makes it easier

to connect the two cables for power and outputs to

the terminals in the rear terminal box.

2.4.2 Pressure measurement with built-in sensor

Cable diameter

To conform to protection category requirements,

observe the following recommendations

Cable diameter : 8 to 13 mm (0.31” to 0.51”)

Enlarge the inside diameter of the Screwed conduit

entry by removing the appropriate onion ring(s)

from the seal,only if cables have extremely tight

fit.

Fit blanking plug PG 16 and apply sealant to

unused cable entries.

Do not kink cables at conduit entries.

Provide water drip point (U bend in cable).

Conduit Installation, general wiring considerations

When electrical codes require conduit, it must be

installed in such a manner that the meter

connection compartment remains

dry

at all times.

Power and output wiring should be run in a

separate conduit.

Use twisted pair for output wiring.

WARNING

Power wiring should utilize a grounded

conductor to avoid possible shock hazard and damage

to component parts.

2.4.3 Pressure measurement by external means

3.2 Connection to power

Note information given on the instrument name

plate (voltage, frequency)!

·

·

·

·

·

·

Electrical connection in conformity with VDE

0100 “Regulations governing heavy-current

installations with rated voltages up to 1000V” or

equivalent national standard.

The

PE protective ground conductor

for supply

power must be connected to the separate U-clamp

terminal in the terminal box of the signal

converter.

Do not cross or loop cables in the terminal box of

the signal converter. Use separate PG or NPT

screwed conduit entries for power and output

cables.

Ensure that the

screw thread of the round cover

on the terminal box is well greased at all times.

Connection to power, VFM 5090(I)

5