2

. Installation in the pipeline

2.1 General

1

.

Flow direction and meter position

·

·

·

Flow must always be in the direction of arrow,

bluff side of vortex-shedding body facing

incoming flow i.e. upstream side.

Vertical pipe run : upward flow direction

Horizontal pipe run : see below

2.

Difference between inside diameter of primary

head and pipeline

DN

F

Meter size of primary head in mm or inches.

Inside diameter of primary head in mm or inches.

Part A System installation and Start-up

DF

Max. allowable difference between inside

diameters of primary head and pipeline.

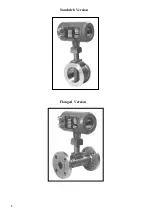

1. Description

KHRONE MARSHALL Vortex Flowmeter

operate on the Karman vortex street principle to

measure volumetric flow rate of gases / steam

and liquids. VFM computes normalized

volumetric and mass flow rates from operating

Pressure and Temperature values, or from density

values. Temperature sensor is standard &

pressure sensor is optional to provide an on-line

P&T compensation.

Items included with shipment

·

·

·

·

·

Compact Vortex Flowmeter

Installation and operating instructions

Mounting bolts, washers, nuts

Plastic cover wrench for electronic housing

·

Optional upstream & downstream pipes

·

Programming chart indicating factory

configuration settings.

Gaskets between primary head and pipeline.

Provided by customer

·

All cables for electrical connections.

SIZE

f

Df

SIZE

f

Df

DN

(mm)

mm

(inch)

mm

(inch)

DN

(inch)

mm

(inch)

mm

(inch)

10S

8.9

(0.35)

0.4

(0.016)

3/8"S 8.9

(0.35)

0.4

(0.016)

10

12.6

(0.50)

0.4

(0.016)

3/8" 12.6

(0.50)

0.4

(0.016)

15

14.9

(0.59)

0.4

(0.016)

1/2" 14.9

(0.59)

0.4

(0.016)

20

20.9

(0.82)

0.4

(0.016)

3/4" 20.9

(0.82)

0.4

(0.016)

25

28.5

(1.12)

0.4

(0.016)

1" 26.7

(1.05)

0.4

(0.016)

40

43.1

(1.70)

0.4

(0.016)

1/5" 40.9

(1.61)

0.4

(0.016)

50

54.5

(2.15)

0.6

(0.024)

2" 52.6

(2.07)

0.6

(0.024)

80

82.5

(3.25)

0.6

(0.024)

3" 78

(3.07)

0.6

(0.024)

100

107.1

(4.22)

0.6

(0.024)

4" 102.4

(4.03)

0.6

(0.024)

150

159.3

(6.27)

0.8

(0.031)

6" 154.2

(6.07)

0.8

(0.031)

200

206.5

(8.13)

1

(0.039)

8" 202.7

(7.98)

1

(0.039)

Ensure that the bore of locating pipes are smooth and without

deposits or scaling of welding beads.

3. Straight, unimpeded inlet and outlet runs

D=Meter size (Nominal Dia. DN)

INLET OUTLET

1