14. Service call message

Field Service Ver. 1.0 May 2006

202

magicolor 7450

T

roubleshooting

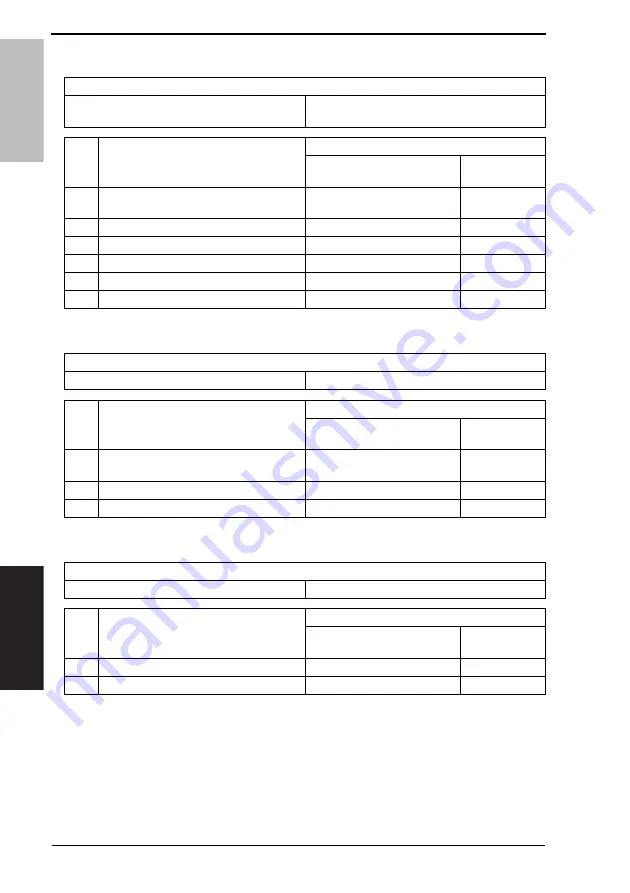

14.3.44

0F3D: Black TCR Sensor adjustment failure

14.3.45

13B0: RTC failure

14.3.46

13C8: Transfer Unit New Article Release

Relevant Electrical Parts

Imaging Unit /K

Toner Supply Motor C/K (M7)

Mechanical Control Board (PWB-M)

Controller Board (PWB-P)

Step

Action

WIRING DIAGRAM

Control Signal

Location (Electri-

cal Component)

1

Clean or correct each contact of the

Imaging Unit if faulty.

—

—

2

M7 operation check

PWB-M CNDM3-10 to 13

C-23

3

Reinstall Imaging Unit /K

—

—

4

Change Imaging Unit /K

—

—

5

Change PWB-M

—

—

6

Change PWB-P

—

—

Relevant Electrical Parts

RTC Board (PWB-R)

Mechanical Control Board (PWB-M)

Step

Action

WIRING DIAGRAM

Control Signal

Location (Electri-

cal Component)

1

Check the connector for proper connection

and correct as necessary.

—

—

2

Change PWB-R

—

—

3

Change PWB-M

—

—

Relevant Electrical Parts

Mechanical Control Board (PWB-M)

Step

Action

WIRING DIAGRAM

Control Signal

Location (Electri-

cal Component)

1

Reinstall Unit

—

—

2

Change PWB-M

—

—

Summary of Contents for magicolor 7450

Page 1: ...SERVICE MANUAL 2006 05 2006 05 Ver 1 0 Ver 1 0 FIELD SERVICE magicolor 7450 magicolor 7450 ...

Page 3: ...ii Blank Page ...

Page 26: ...SERVICE MANUAL 2006 05 Ver 1 0 FIELD SERVICE Main Unit magicolor 7450 magicolor 7450 ...

Page 43: ...2 Product specifications Field Service Ver 1 0 May 2006 6 magicolor 7450 General Blank Page ...

Page 288: ...SERVICE MANUAL 2006 05 Ver 1 0 FIELD SERVICE Lower Feeder Unit ...

Page 317: ...3 Other Field Service Ver 1 0 May 2006 26 Lower Feeder Unit Maintenance Blank Page ...

Page 328: ...SERVICE MANUAL 2006 05 Ver 1 0 FIELD SERVICE Duplex Option ...

Page 333: ...1 Product specifications Field Service Ver 1 0 May 2006 2 Duplex Option General Blank Page ...

Page 345: ...6 Jam Display Field Service Ver 1 0 May 2006 14 Duplex Option Troubleshooting Blank Page ...