MAINTENANCE

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

4-13

NOTICE

Use only diesel fuel.

The engine mounted on this machine employs electronic control and a high-pressure fuel injection device

to obtain good fuel consumption and good exhaust gas characteristics. For this reason, it requires high

precision for the parts and good lubrication.

If kerosene or other fuel with low lubricating ability is used, there will be a big drop in durability.

Always use the fuel specified for the temperature in the Operation and Maintenance Manual.

q

If the fuel is used at temperatures lower than the specified temperature (particularly at temperatures below -

15°C), the fuel will solidify.

q

If the fuel is used at temperatures higher than the specified temperature, the viscosity will drop, and this may

result in problems such as a drop in output.

Note. 1: HTHS (High-Temperature High-Shear Viscosity 150°C), specified by ASTM D4741 must be equal to or

higher than 3.5 mPa-S. Komatsu EOS0W30 and EOS5W40 are the most suitable oils.

Note. 2: Powertrain oil has different properties from engine oil. Be sure to use the recommended oils.

Note. 3: Axle oil AXO80 has the function of preventing squealing from the brakes and LSD (Limited Slip Differen-

tial).

If only AXO80 is recommended, use Komatsu genuine AXO80 or equivalent.

Note .4: When the ambient temperature is higher than 45°C and the machine operation hour is longer than 12

hours/day, then the use of EO50-CD instead of AXO80 is recommended.

Squealing of the brakes may occur with EO50-CD, but there is no problem with the brake performance or durabil-

ity.

Note. 5: If the machine is equipped with automatic greasing system, see “HANDLING AUTO-GREASING SYS-

TEM (6-3)“.

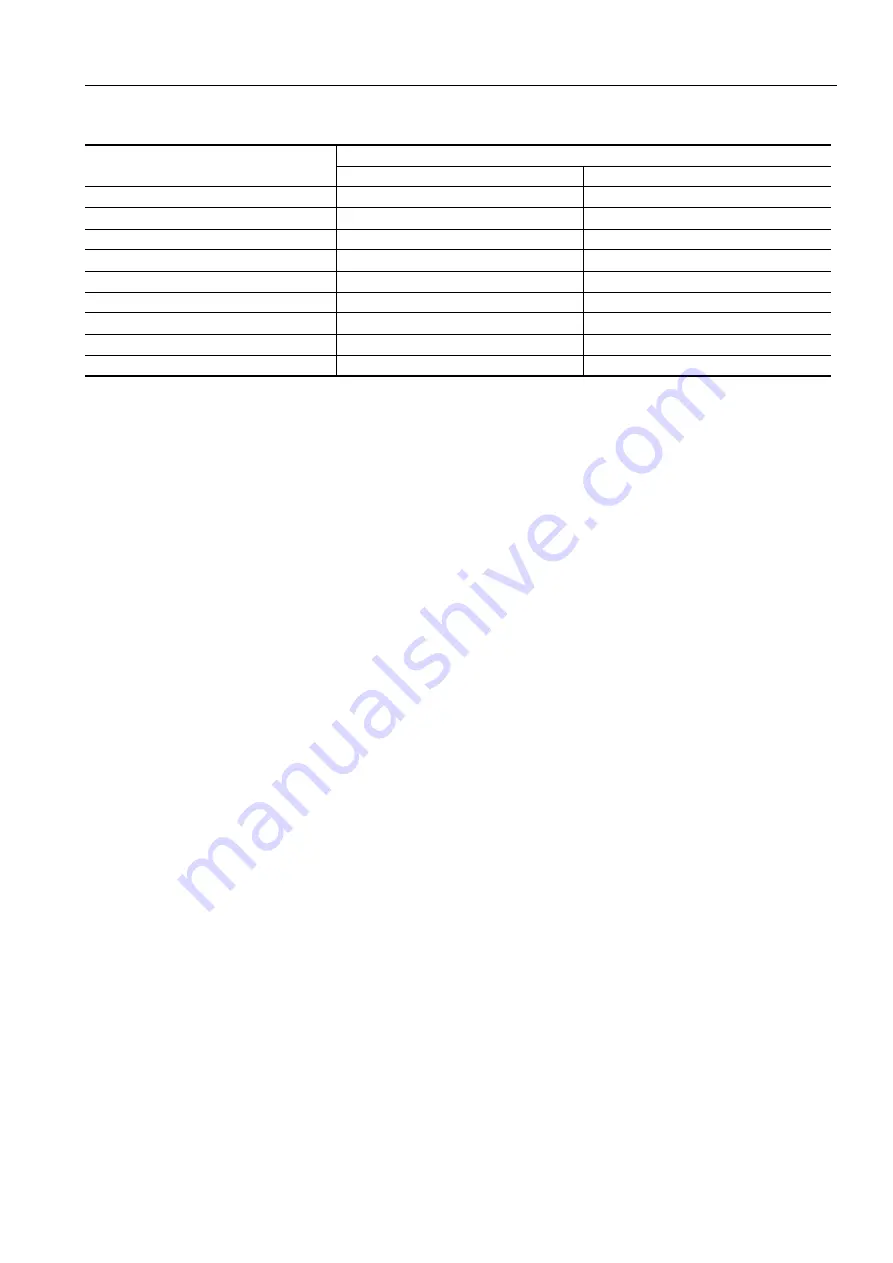

Reservoir

Reservoir Capacity (Liters)

Specified

Refill

Engine oil pan

140

130

Transmission case

164

140

Hydraulic system

1065

725

Brake oil tank

42

31

Front axle (each)

360

360

Rear axle (each)

360

360

Pins

-

-

Fuel tank

1555

-

Cooling system

337

-

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...