5.10

Section 5

Fuel System and Governor

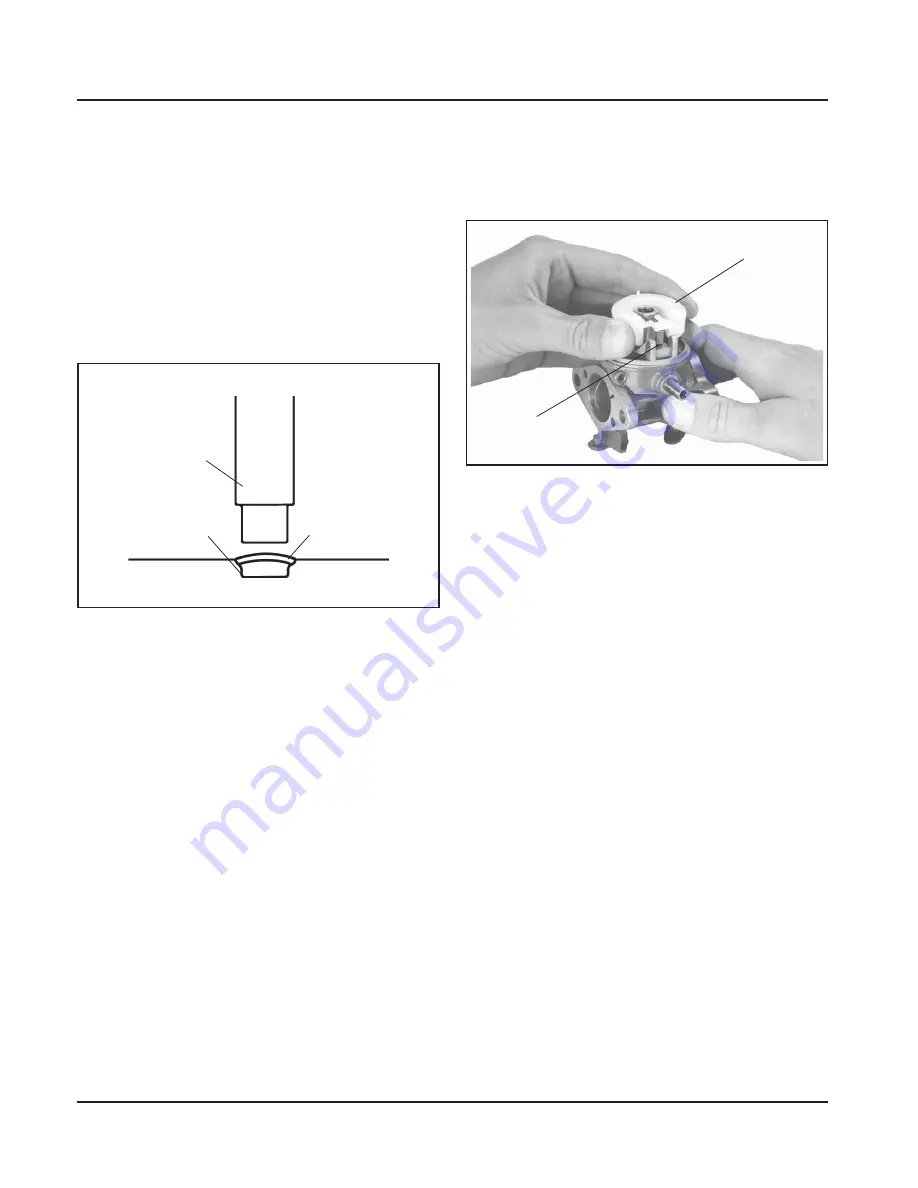

Figure 5-14. Installing Float and Fuel Inlet Needle.

5. Install the bowl gasket, fuel bowl, bowl retaining

screw gasket, and bowl retaining screw or fuel

solenoid.

Torque the bowl retaining screw to

5.1-6.2 N·m

(45-55 in. lb.)

.

High Altitude Operation

When operating the engine at altitudes of 1830 m

(6000 ft.) and above, the main fuel mixture tends to

get overrich. An overrich mixture can cause conditions

such as black, sooty exhaust smoke, misfi ring, loss

of speed and power, poor fuel economy, and poor or

slow governor response.

To compensate for the effects of high altitude, a

special high altitude main fuel jet can be installed.

High altitude jets are sold in kits which include the jet

and necessary gaskets. Refer to the Parts Manual for

the engine being serviced for the correct kit number.

Fuel Shut-off Solenoid (Optional)

Some gasoline-fueled engines are equipped with

the optional fuel shut-off solenoid, which is installed

in place of the bowl retaining screw, to eliminate

backfi ring when the engine is shut down. If a solenoid-

equipped engine will not start, check whether suffi cient

voltage is reaching the solenoid. A minimum of 7.3

volts DC is required to activate the solenoid. Also

check to see that the ground lead from the carburetor

body to the air cleaner base mounting stud is properly

connected.

Figure 5-13. Installing Welch Plugs.

4. After the plugs are installed, seal them with

Glyptal

™

(or an equivalent sealant). Allow the

sealant to dry.

NOTE: If a commercial sealant is not available,

fi ngernail polish can be used.

Carburetor Reassembly

1. Install the low idle speed adjusting screw and

spring.

2. If removed during disassembly, install the low

idle fuel adjusting needle and spring. Turn the

adjusting needle

in

(clockwise) until it bottoms

lightly

.

NOTE: The tip of the idle fuel adjusting needle is

tapered to critical dimensions. Damage

to the needle and the seat will result if

the needle is forced.

3. Turn the low idle fuel adjusting needle out

(counterclockwise) 1 turn.

Float

Fuel Inlet Needle

Welch Plug Installation–Walbro Carburetors

Use Tool No. KO1017 and install new plugs as follows:

1. Position the carburetor body with the welch plug

cavities to the top.

2. Place a new welch plug into the cavity with the

raised surface

up

.

3. Use the end of the tool that is about the same

size as the plug and

fl atten

the plug. Do not force

the plug below the surface of the cavity. See

Figure 5-13.

Tool No. KO1017

Carburetor Body

New Welch Plug

4. Insert the fuel inlet needle into the fl oat. Lower

the fl oat/needle into the carburetor body. See

Figure 5-14.

Install

the

fl oat shaft.

Summary of Contents for CV11-16

Page 1: ...1 SERVICE MANUAL VERTICAL CRANKSHAFT CV11 16 CV460 465 CV490 495...

Page 2: ......

Page 4: ......

Page 22: ...2 4 Section 2 Special Tools...

Page 30: ...4 4 Section 4 Air Cleaner and Air Intake System...

Page 56: ...6 6 Section 6 Lubrication System...

Page 112: ...9 16 Section 9 Disassembly...

Page 148: ...11 24 Section 11 Reassembly...

Page 149: ......