17

1

Introduction

Please check the following items upon receipt of the product.

If there are any problems, contact your dealer.

・ Confirm the upside of the package and open the package carefully. Failure to do

may result in injuries.

・ Do not load handing with the band. There is a possibility that it may be injured

by the band off.

・ This product is skewed center of gravity. Lifted carelessly may occur to be low

back pain.

・ Check the nameplate to ensure that the correct pump has been delivered.

Check the type, output, voltage, frequency, etc. of the delivered pump in reference

with the name plate to verify that the correct product has been delivered.

・ Check that no parts have been damaged during transportation, and that none of

the bolts, nuts, etc., are loose. Tighten any part that is loose.

・ Check that all ordered accessories have been delivered.

2

Specifications

●

●

●

●

●

Always use this pump within the specified product specifications.

Failure to do so could result in electric shocks, fires, water leaks, etc.

Never use this product above the maximum working pressure. There is a risk of

serious accidents.

Caution is required when using this product in a circulatory application, in which

there is no tolerance for rusting, metal corrosion or elution. Carefully select and

review the pump and entire system. The circulating water could become

concentrated and lead to unforeseen damage.

Select a product that matches the application. Using a product for an inappropriate

application will cause faults.

The Danger, Warning and Caution labels indicate information on matters that could

cause bodily harm or property damage. Always observe the indicated information.

Failure to do so could result in device damage, electric shock, fire or injury, etc.

Caution

2.1 All the model community

Coolant,Cutting oil

※The pump cannot be used with fresh water, ocean water, organic solvent,

acid liquid.

Also, using high viscosity fluids will shorten the life of the motor and may cause

the motor to burn out.

Be sure to use the fluids with the viscosity within the limit in the specification list.

Note that the viscosity may greatly increase as the fluid temperature decreases.

Check the viscosity when the temperature of the fluid in use is lowest.

0〜40℃

Contents

Temperature

Viscosity Max 75 mm

2

/

s

(RCD-40HA(B)3.0(T4) Type : 60mm

2

/

s

)

Always use the pump indoor in a location free of flammable gas or steam

and at an altitude of 1,000m or less.

0〜40℃

Humidity Under 85%RH

Vertical only

Because the suction port is on the bottom of the pump in the pump section, secure

at least 15 mm between the bottom of the tank and the suction port.

Outlet

Rp 1

1

/

2

Noise level

Under 80dBA

Type

Totally enclosed fan- cooled indoor model.

Phase

3Phase

200V Type

50Hz:200V

60Hz:200-220-230V

400V Type

50Hz:380-400V

60Hz:400-440-460V

Ambient

temperature

Fluid

Installation

location

Installation requirements

Suction conditions

Motor

Voltage

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

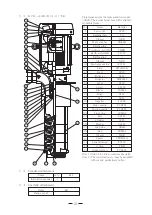

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...