23

Basic Model

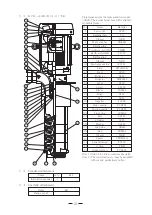

6:00

3:00

12:00

Terminal

Box

Discharge

9:00

VC80

VC82

VC81

B

A

Lowest

Liquid

Level

Highest

Liquid

Level

※Please put in calmly and not to involve in air,

When putting use liquid into a tank.

4.The tank should use as big capacity as possible.

The recommended tank capacity is at least three times of discharge amount per

minute.

Using a tank with excessively small capacity may cause problems, such as the fluid

temperature increasing, the strainer clogging with cutting chips faster than usual,

reduction in the amount of discharge due to generation of bubbles, etc.

5.Attach to a tank, certainly fix to the hole of attachment in the flange of a pump.

Although there are 2x2 attachment holes, it is for expanding the use range and

please fix actual attachment at two places of the direction of a diagonal.

Since the attachment hole is capping, please remove only two caps to be used.

Two places which remain should not remove a cap but should use it as it is.

6.The operating liquid level is as follows.

・Highest liquid level

For safety, keep the fluid level as low as possible.

・Lowest liquid level

For safety, keep the fluid level as high as possible.

7.Position change of a terminal box serves as special

specification.

Depend on specialist on the site when a change is

necessary.

The terminal box position can change a position

every 90 degrees by rearranging a motor frame.

(Refer to right figure)

Type

RCD-40A(E)0.75(T4)

RCD-40A(E)1.5(T4)

RCD-40B(E)1.5(T4)

RCD-40A(E)2.2(T4)

RCD-40(E)B2.2(T4)

RCD-40(H)A(E)3.0(T4)

RCD-40(H)B(E)3.0(T4)

20

20

20

20

20

20

20

200

200

350

200

350

250

350

Highest liquid

level A[mm]

Lowest liquid

level B[mm]

5

Piping

5.1 Piping

1.Install a vibration proof joint and piping support to prevent

the piping weight from being applied directly to the pump.

2.The piping should be as following

The pipe should be as big as possible and as short as possible.

The pipe should reduce a bent elbow and a branch such as cheese. Reduce the

obstacles such as valves.

※When a pipe is long and is small, and there are many a curve and obstacles, a

discharge decreases.

3.Tighten certainly in the screw part of piping using seal adhesive to prevent water leakage.

Do not forcibly screw the pipes into the pump. Failure to observe this could damage

the joints.

The clamping torque of the screw please refer to a list shown below.

4.Take appropriate preventive measures to prevent water hammer (e.g. install an

By-pass etc.).

5.We prepare square flange as special accessories, please contact your dealer.

Screw size

Rp 1̲1/2

(Ref.)Tightening torque

180 [N・m]

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...