26

8

Maintenance and Inspection

●

●

●

●

●

●

●

●

If the pump does not operate or if an abnormality is sensed (such as burning smell),

stop operation immediately and turn OFF the main power. Then, contact the place

of purchase or a designated service center for inspections and repairs. Failure to

observe this could result in electric shocks, fires, water leaks, etc.

The product must never be disassembled, repaired or modified by any person other

than a qualified repair technician. Improper repairs could lead to electric shocks,

fires or water leaks.

Always turn OFF the power and ensure that no power is being supplied to the

pump before starting maintenance servicing. Failure to observe this could result in

electric shocks or injuries.

When keep a pump for a long time, please measure the insulation resistance of

winding every six months, and check that it is more than 1MΩ.

Always use genuine Kawamoto parts for repairs. Use of non-genuine parts could

cause faults and accidents. In addition, proper functions may not be achieved.

Both periodic inspections and daily inspections are recommended for ensuring safe

use for a long time. Failure to perform inspections can result in pump faults and

accidents. Consult with your dealer or nearest Kawamoto Sales Office for periodic

inspections.

Periodically replace the consumable parts. Using the pump with degraded or worn

parts can result in water leaks, burning or damage. Contact your dealer or nearest

Kawamoto Sales Office for periodic inspections and part replacement, etc.

Always follow the inspection items when performing inspections. If the inspection

items are not followed, it may not be possible to prevent faults, and could result in

accidents.

Warning

5 . The pressure gauge and compound gauge s cocks should be closed except

measurement.

Leaving these cocks open will increase the risk of damage.

6 . It is not unusual although liquid comes out from between the cover and stage

casings for the structure where the mechanical seal is not used.

7.2 Operation

1.Install valve in the discharge pipe, flow adjustment is possible by opening and

closing of a valve. A motor does not become overload operation even if it closes a

valve.

2.Flow adjustment is possible at good operation in variable speed by an inverter.

When you use an inverter, please operate with the frequency of 5 〜 60 Hz, and below

an amperage rating value.

However, as for an inverter, directions for use should follow an inverter maker's

directions.

There is a possibility that a motor may be damaged by fire depending on the kind of

inverter or a setup.

We recommend to do the conformity examination of an inverter and a pump.

3.The frequency of start and stop makes max100 time an aim every hour .

Operation of high frequency causes failure of electric parts, such as insulated

degradation of a motor.

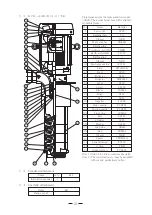

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...