25

7

Operation

●

●

●

●

●

●

Always turn OFF the power and ensure that no power is being supplied to the

pump when attaching or disconnecting wiring. Failure to observe this could result

in electric shocks.

Do not pour water into the motor. Failure to observe this could result in electric

shocks, short circuit, fires, and malfunction.

Always turn the power switch OFF under a power failure. when a power supply

returns, suddenly operation could in injuries.

Do not bring hands and feet close to a suction port during operation. Failure to

observe this could result in injuries by being inhaled.

Do not use or perform work while the product is suspended. There is risk of

dropping and injury.

Do not start operation with the shaft joint guard removed. Objects could get caught

in or contact the rotating section and fly around and cause injury.

Warning

●

●

●

●

●

●

●

●

●

Do not use this product out of the rated voltage. Failure to observe this could result

in fires or electric shocks.

Do not touch the rotating area during operation, and do not insert fingers or rods,

etc. into the motor openings. Failure to observe this could result in electric shocks

and injuries.

Do not touch pump or motor during operation . The motor could reach high

temperature and lead to burns.

Turn OFF the power when not using the pump for long periods of time. Failure to

observe this could result in earth leakages, electric shocks, or fire due to

deterioration of the insulation.

Do not use the product over the frequency 60Hz (50Hz only model is 50Hz) when

driven with an inverter. Failure to observe this could result in the pump burning

out or fires.

When operating the motor with a 400V class inverter, install a suppressing filter or

reactor on the inverter side , or reinforce the motor side with insulation. Failure to

observe this could lead to damage or fires due to insulation breakage.

Do not use a fluid with a higher viscosity than the maximum limit of viscosity.

Failure to observe this could result in the pump burning out or fires.

Do not place flammable objects near the pump. Failure to observe this could result

in fires if a power plug generates heat and ignites.

When resuming operation after a long-term storage or suspension, refer to the

"Installation" and "Operation" sections and perform trial operation. The pump could

be locked and the motor could burn if parts are stuck, etc.

Always operate the pump within the specified range. Operation exceeding the

specified range could result in pump damage or accidents.

Caution

7.1 Trial operation

1.Verify that the earth leakage breaker capacity, the power supply voltage, and the

wiring are correct.

2.Check that the fluid is above the specified level.(Refer to 4 . 1 - 6)

3.Turn the power ON, and confirm the rotation direction of the pump accords with the

arrow on the fan cover . If 3-phase rotation is reversed, turn the source power supply

OFF, then replace the connections of 2 of the 3 wires.

4.Confirm that coolant or cutting oil are discharged . Verify that the voltage, current,

vibration, and noise conditions, etc., are no abnormality.

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

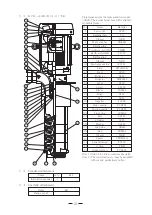

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...