16

87400011

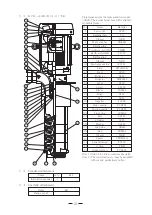

Coolant Pump RCD Type

Instruction Manual

Thank you for purchasing the dirty type coolant pump RCD.

This instruction manual provides information for the customer

to safely use this pump unit.

Always read this manual thoroughly and fully comprehend

the contents before starting work.

Please keep this instruction manual in a handy place for

quick reference

< Contents >

Special Notes

1.This product must never be disassembled, repaired or modified by any

person other than a qualified repair technician. Improper repairs could lead

to electric shocks, fires or water leaks.

2.Always turn the power OFF and make sure that power is not being

supplied before starting maintenance servicing. Failure to observe this

could result in electric shocks or injuries.

3. Securely earth the equipment, and install a dedicated residual current

circuit breaker on the power supply side. Failure to observe this could

result in earth leakages, electric shocks or fires.

Caution

Warning:Details which if ignored could lead to fatalities or serious injuries.

:Details which if ignored could lead to personal injuries or physical damage.

Precautions for using this product safely and for preventing personal injuries or

physical damage are given in this manual.

The warranty may exclude trouble resulting from use in a manner outside the

prescribed range, failure to observe precautions, inappropriate

repairs/modifications or natural disasters; trouble resulting from installation

environment (power error, foreign matter, sand, etc.); trouble resulting from

failure to comply with laws, regulations and applicable standards; and trouble

resulting from accidental or intentional faults and damage, replacement of

consumable parts or sale of product, etc.

The precautions are classified as Warning and Caution to alert of the

degree of injury or damage that could occur if handling is mistaken.

In either case, these are important matters related to safety, and must be

observed.

1

2

3

4

5

Introduction ・ ・ ・・・・17

Specifications ・ ・ ・ ・・・17

Configuration ・ ・ ・・・・20

Installation ・ ・・・・・ 22

Piping ・ ・・・・・23

6

7

8

9

10

Electrical Work ・・・・・・・・・24

Operation ・・・・・・・・・・・ 25

Maintenance & Inspection・・・・・ 26

Trouble shooting ・・・・・・・・ 27

Disposal ・・・・・・・・・・・・28

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...