Head office:No. 11−39 4−chome, Ohsu Naka−ku Nagoya, 460−8650 Japan

Kawamoto Pump Mfg. Co., Ltd.

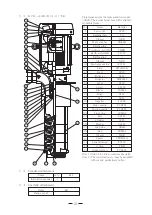

Refer

page

24,25

−

−

−

−

−

−

23

−

−

−

17

22

−

−

−

−

・Unexpected trouble could occur. However, it is important to take appropriate measures immediately

when an abnormal condition is found.

・If the cause of the trouble is not clear, contact your dealer or designated service center.

Notice the pump type, serial No. and trouble (fault) state making an inquiry.

●

When you discard a pump and parts, please process in accordance with the law of

the country (area).

Caution

10

Disposal

Cause

Countermeasure

Problem

Pump rotation direction is

reversed.

Impeller is clogged with foreign

matter.

The strainer is clogged with

foreign objects.

The pipe is clogged.

Worm parts.

Air has collected in the pump.

Large amount of bubbles in fluid.

An operating fluid level is as lower

as the lowest fluid level.

Piping loss is high.

Voltage is too low or unbalanced.

The bearing of a motor is worn

out or damaged.

Viscosity of fluid is too high.

Installation defect.

The foreign substance is got

blocked in the impeller.

The bearing of a motor is worn

out or damaged.

O-ring(packing) is damaged.

Water hammer occurs when a

valve is closed suddenly.

Correct the wiring.

Have specialist repair.

Have specialist repair.

Inspect and repair.

Have specialist repair.

A pump is suspended and it is

started again. Air is extracted from

an air bleed valve.

Prevent bubble generation/suction.

Adjust fluid level.

Review piping.

Adjust voltage.

Have specialist repair.

Use fluid with lower viscosity.

The check of an installation state.

Have specialist repair.

Have specialist repair.

O-ring(packing) is exchanged.

Install an accumulator or bypass

circuit.

Pump rotates, but no

water is discharged.

Prescribed discharge

amount/pressure is

not obtained

Overload (over-current)

occurs.

There is vibration or

abnormal noise.

Fluid leaks.

Water hammer

occurrence.

Summary of Contents for RCD-40A0.75

Page 1: ...1...

Page 2: ...2...

Page 3: ...3 kW Hz min kg V V kW Hz min kg RH Rp dBA Hz Hz Hz Hz...

Page 4: ...4 kW Hz min kg V V kW Hz min kg kW Hz min kg...

Page 5: ...5 3 M M W K No...

Page 6: ...6 3 3 3 M M W K No...

Page 7: ...7...

Page 8: ...8 B A m s2 1 m B...

Page 9: ...9 VC81 6 3 VC82 12 9 VC80 m...

Page 10: ...10 m m V kW mm mm...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13 2...

Page 14: ...14...

Page 15: ...15...