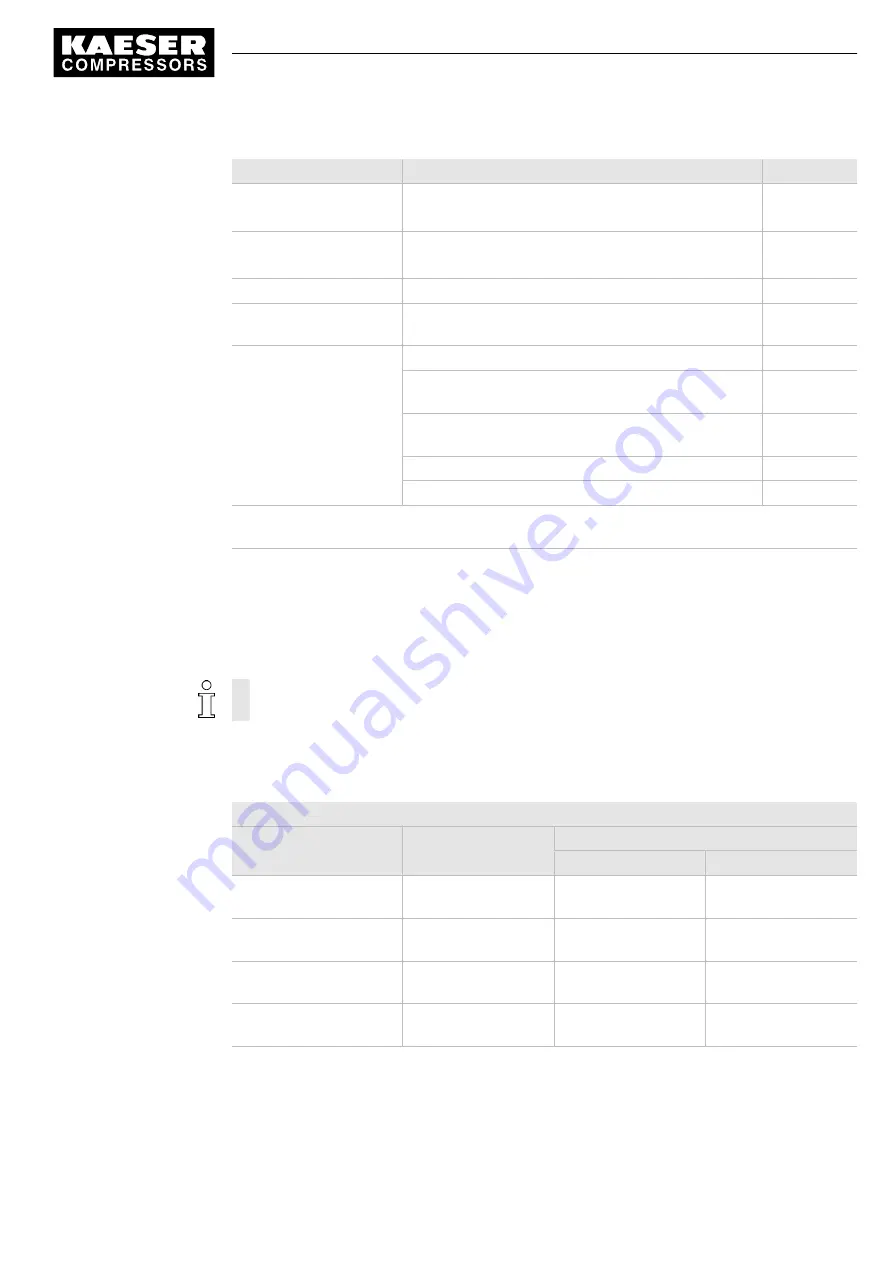

Interval

Maintenance task

See chapter

Up to 3,000 h/6,000 h*

At the latest every 3 years

Change the oil separator cartridge.

Up to 3,000 h/6,000 h*

At least annually

Change the oil filter.

Change the cooling oil.

Variable

Check the compressed air filter.

(option F1 F2)

Annually

Check that all electrical connections are tight.

–

Compressor

Check the safety relief valve.

Air receiver

Check the safety relief valve.

Check the overheating safety shutdown function.

Check the cooler for leaks.

h = operating hours

*When using SIGMA FLUID S-460

Tab. 35 Regular maintenance tasks

10.2.4 Cooling oil changing interval

Machine utilization and ambient conditions are important criteria for the number and length of the

change intervals.

Authorized KAESER Service representative will support you in determining appropriate inter‐

vals and provide information on the possibilities of oil analysis.

➤ Please observe national regulations regarding the use of cooling oil in oil-injected screw com‐

pressors.

➤ Check operating conditions and adjust intervals as necessary.

KAESER LUBRICANTS

SIGMA Lubricant

Description

Maximum Recommended Change Interval

First oil change

Subsequent oil change

M–460

ISO 46 Semi-Synthetic

Lubricant

2,000 Hours

3,000 Hours

S–460

ISO 46 Synthetic Lubri‐

cant

6,000 Hours

8,000 Hours

S–680

ISO 68 Synthetic Lubri‐

cant

6,000 Hours

8,000 Hours

FG–460

ISO 46 Food Grade

Synthetic Fluid

2,000 Hours

3,000 Hours

Tab. 36 Oil change intervals lubricants

10 Maintenance

10.2 Maintenance Schedule

Number: 9_6945 01USE

Service manual Screw compressor

Aircenter SX 3/7.5 SIGMA CONTROL BASIC

55