Replace the drive belts

The drive motor must be moved in its bracket to change the belts. Use the appropriate tool and support

the motor during belt changing.

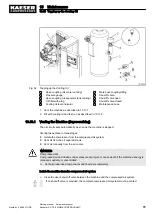

Fig. 29 Changing the belt

1

Fixing screw

2

Pivot point fixing screw

3

Tensioning nut

4

Markings

5

Tensioning device

1. Loosen the tensioning nut

3

by approx. 0.4 in.

2. Remove the fixing screws

1

.

3. Loosen the pivot point fixing screw

2

only sufficiently to allow the motor to shift to the side.

4. Move the motor to the side and fix it in position with a screw

1

.

5. Place the new belts over the pulleys.

6. Ensure that all fixing screws

1

are loosened.

7. Tighten the belts by means of the tensioning nut

3

until the markings

4

coincide.

8. Tighten one fixing screw

1

to hold the motor in place then tighten the rest

1

and

2

.

Result The drive belts are sufficiently tensioned.

It is not necessary to re-tension the belts.

10.9 Pressure relief valve checking

In order to check the activating pressure of the pressure relief valve, the machine's working pressure

is raised above the set activating pressure of the valve.

The controller is switched to the pressure relief valve checking mode to carry out this check. This

checking mode is intended for machines with maximum permissible working pressure less than 217

psig. Pressure relief valves in machines with permissible working pressures higher than 217 psig

must be removed from the machine and tested on a special rig.

10 Maintenance

10.9 Pressure relief valve checking

60

Service manual Screw compressor

Aircenter SX 3/7.5 SIGMA CONTROL BASIC

Number: 9_6945 01USE