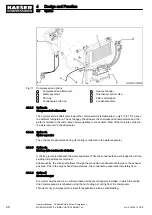

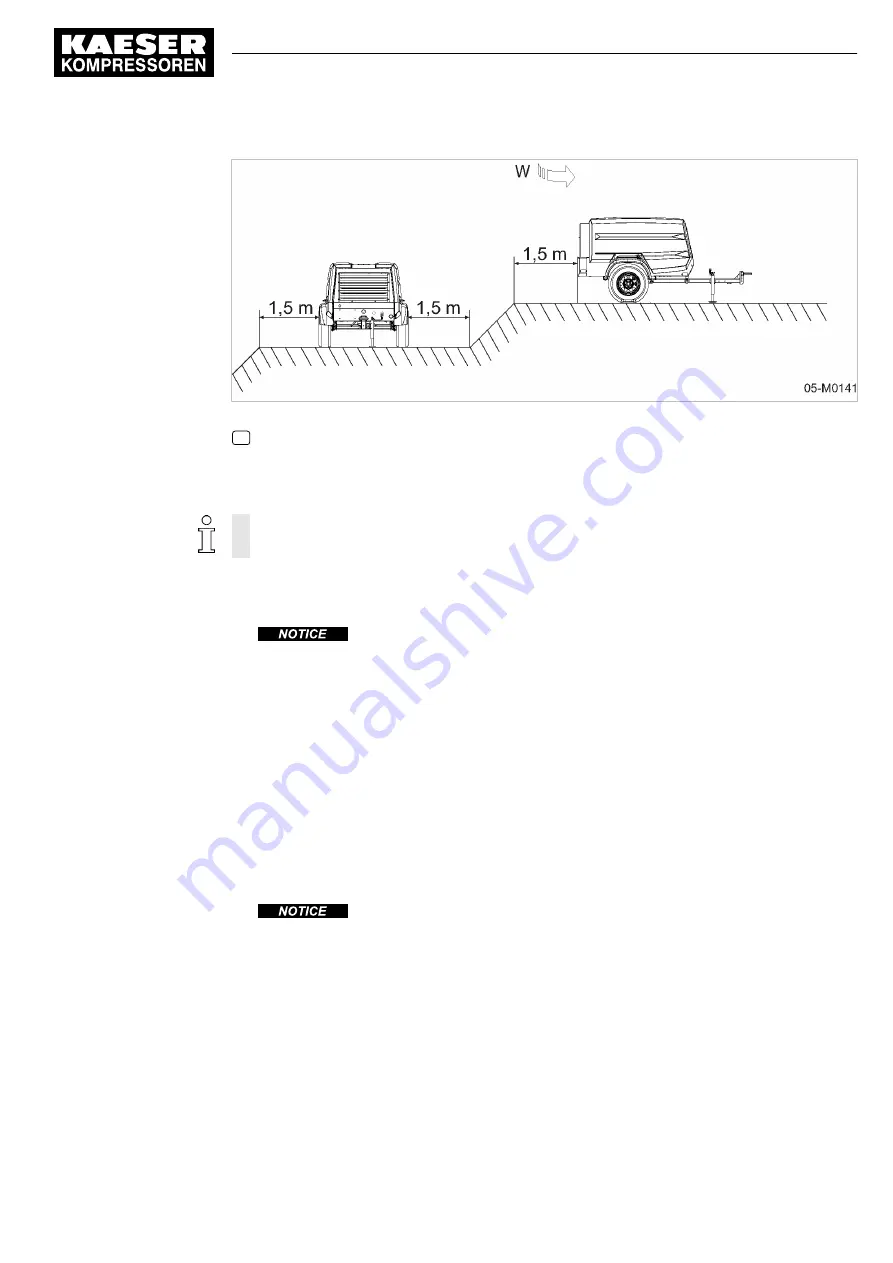

Fig. 14 Minimum distance from excavations/slopes and walls

W

Wind direction

1. Keep sufficient distance (at least 5 ft) from the edges of excavations and slopes.

2. Ensure that the machine is as level as possible.

The machine can be temporarily operated on a slope of not more than 15°.

3. Ensure accessibility so that all work on the machine can be carried out without danger or hin‐

drance. The operator panel with the «EMERGENCY STOP» push button must be accessible

and within reach at any time.

4.

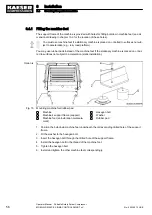

Fire hazard from build-up of heat and hot exhaust system!

Insufficient clearance above the machine may well cause heat build-up that could damage the

machine.

➤ Do not position the machine directly under a low roof or covering.

➤ Ensure always sufficient ventilation space around the machine.

5. Ensure there is enough free space all round and above the machine.

6. Keep air inlet and outlet openings free of obstructions so that the cooling air can flow freely

through the machine.

7. Install the machine ensuring that

■ Exhaust gases and heated exhaust air can escape freely.

■ Do not allow exhaust gases and heated cooling air to be drawn into the compressor.

Note the wind direction! (see figure 14)

■ Ensure the unimpeded intake of fresh air (air intake, cooling air).

8.

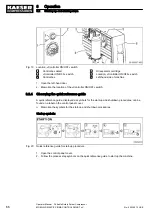

Ambient temperature too low.

Frozen condensate and highly viscous engine or compressor cooling oil can cause damage

when starting the machine.

➤ Use winter grade engine oil.

➤ Use winter diesel fuel.

➤ Use low viscosity compressor cooling oil.

9. At ambient temperatures below 32 °F, follow the instructions in chapter 7.4.

5

Installation and Operating Conditions

5.2

Installation conditions

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

53