5 Installation and Operating Conditions

5.1 Ensuring safety

The conditions in which the machine is installed and operated have a decisive effect on safety.

Warning instructions are located before a potentially dangerous task.

Disregard of warning instructions can cause serious injuries!

Complying with safety notes

Disregard of safety notes can cause unforeseeable dangers!

➤ Strictly forbid fire, open flame and smoking.

➤ If welding is carried out on or near the machine, take adequate measures to prevent sparks or

heat from igniting fuel or oil vapours or parts of the machine.

➤ Do not store inflammable material in the vicinity of the machine.

➤ The machine is not explosion-proof:

Do not operate in areas in which specific requirements with regard to explosion protection are

in force.

For instance, the requirements of ATEX directive 2014/34/EC "Equipment and Protective Sys‐

tems intended for use in Potentially Explosive Atmospheres".

➤ Keep suitable fire extinguishing agents ready for use.

➤ Ensure that required ambient conditions are maintained.

Required ambient conditions may be:

■ Ambient temperature

■ Air composition at the installation site:

─ clean with no damaging contaminants (e.g., dust, fibres, fine sand)

─ free of explosive or chemically unstable gases or vapours

─ free of acid/alkaline forming substances, particularly ammonia, chlorine or hydrogen sul‐

phide.

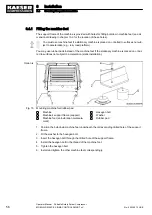

5.2 Installation conditions

Precondition The floor must be level, firm and capable of bearing the weight of the machine.

5

Installation and Operating Conditions

5.1

Ensuring safety

52

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE