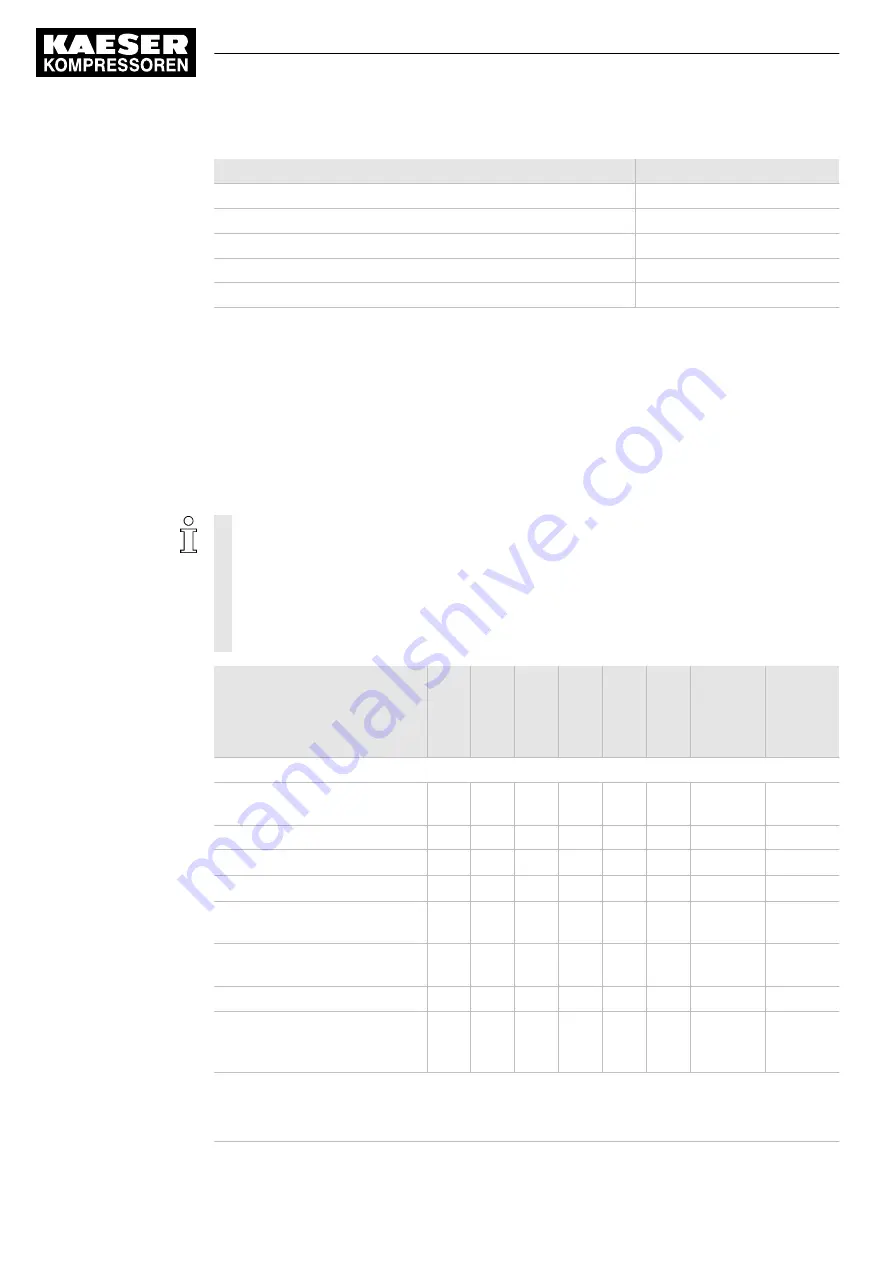

Maintenance interval

Short description

Every 250 h, at least annually

A250

Every 500 h, at least annually

A500

Every 1000 h, at least every 2 years

A1000

Every 1500 h, at least every 3 years

A1500

Every 3000 h, at least every 6 years

A3000

Tab. 71 Maintenance intervals and regular maintenance tasks

The table below lists regular maintenance tasks.

1. Carry out maintenance tasks in a timely manner, taking ambient and operating conditions into

consideration.

2. Change spare parts and operating fluids according to each site.

10.3.3.1 Machine maintenance schedule

➤ Carry out maintenance tasks on time in accordance with the table below:

The maintenance tasks marked with

(1)

depend on the engine oil and fuel used. The replace‐

ment intervals can be halved when using low-quality operating fluids/materials.

Observe the maintenance activities marked with

(2)

in accordance with country-specific regu‐

lations.

Change the oil as per requirement, once per year at a minimum.

Observe the maintenance tasks marked with

(3)

in accordance with country-specific regula‐

tions.

Assembly:

Task

Daily

A250

A500

A1000

A1500

A3000

See Chapter

Note

Engine:

Check engine air filter mainte‐

nance indicator.

X

Check engine oil level.

X

(1)

Change engine oil.

X

(1)

Change engine oil filter.

X

Change the oil separator ele‐

ment.

X

Check/adjust the drive belt ten‐

sion.

X

KS; SW

Change the drive belt.

X

KS; SW

Clean the primary filter element

of the engine air filter, replace if

necessary.

X

KUBOTA = Is serviced by a representative from the engine manufacturer (Kubota Corporation)

KS = Contact KAESER SERVICE; SW = Contact Specialist Workshop

DPF = Diesel Particulate Filter

10 Maintenance

10.3 Following the maintenance plans

96

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE