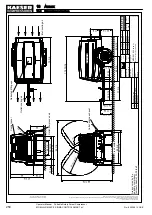

Fig. 74 Example: Transporting a machine by forklift

1

Lifting the machine from the loading

ramp/HGV loading bed

2

Lowering the machine for horizontal trans‐

portation

3

Loading ramp/HGV loading bed

4

Loading sill clearance

5

Incorrect transport height

6

Prohibition sign “Driving with a raised load”

7

Correct transport height

8

Incline the lift mast in the direction of the

arrow

1. Carefully reverse the forklift with the raised machine away from the loading ramp/HGV loading

bed.

2. As soon as the specified horizontal clearance from the loading sill

4

has been reached, apply

the brakes on the forklift.

Forklift comes to a standstill.

3. Lower the fork carriage.

Specified transport height (minimum ground clearance) is reached.

4. Incline the lift mast in the direction of the arrow.

5. Transport the machine at the specified transport height and with inclined lift mast from Point A

to Point B.

12.2.3.6 Lowering the machine

Precondition The forklift has arrived at Point B with the machine raised to the specified transport height.

1. Carefully apply the brakes.

Forklift comes to a standstill.

2. Return the lift mast to the vertical position.

3. Lower the fork carriage as slowly as possible, until both fork prongs have vertical clearance in‐

side the lifting lugs.

The machine is parked on even ground at Point B.

4. Reverse the forklift until both fork prongs are fully withdrawn from the lifting lugs.

12.2.4 Transporting as a load

The type of packing and securing required is determined by the medium of transport. Packing and

securing methods must be such that, with proper handling, the goods arrive at their destination in

perfect condition.

Always observe the applicable accident and safety regulations during transportation.

12 Decommissioning, Storage and Transport

12.2 Transportation

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

235

Option rw