Refer to Fuel Filter/Fuel Pressure Regulator in this

group for information.

The fuel rail is not repairable.

FUEL TANK FILLER TUBE CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a California emissions package and a

Leak Detection Pump (LDP), the cap must be tight-

ened securely. If cap is left loose, a Diagnostic

Trouble Code (DTC) may be set.

FUEL TUBES/LINES/HOSES AND CLAMPS

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped: The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

QUICK-CONNECT FITTINGS

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Some are equipped with

safety latch clips. Some may require the use of a spe-

cial tool for disconnection and removal. Refer to

Quick-Connect Fittings Removal/Installation for more

information.

CAUTION: The interior components (o-rings, clips)

of quick-connect fittings are not serviced sepa-

rately, but new plastic spacers are available for

some types. If service parts are not available, do

not attempt to repair the damaged fitting or fuel line

(tube). If repair is necessary, replace the complete

fuel line (tube) assembly.

DIAGNOSIS AND TESTING

FUEL PUMP PRESSURE TEST

Use this test in conjunction with the Fuel Pump

Capacity Test, Fuel Pressure Leak Down Test and

Fuel Pump Amperage Test found elsewhere in this

group.

Check Valve Operation: The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and

fuel

injectors.

Fuel

pressure

that

has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition. When the elec-

tric fuel pump is activated, fuel pressure should

immediately (1–2 seconds) rise to specification.

All fuel systems are equipped with a fuel tank

module mounted, combination fuel filter/fuel pressure

regulator. The fuel pressure regulator is not con-

trolled by engine vacuum.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH THE ENGINE

OFF. BEFORE DISCONNECTING FUEL LINE AT

FUEL RAIL, THIS PRESSURE MUST BE RELEASED.

REFER

TO

THE

FUEL

SYSTEM

PRESSURE

RELEASE PROCEDURE.

(1) Remove protective cap at fuel rail test port.

Connect the 0–414 kPa (0-60 psi) fuel pressure gauge

14 - 6

FUEL SYSTEM

XJ

DESCRIPTION AND OPERATION (Continued)

Summary of Contents for Cherokee 2000

Page 4: ......

Page 36: ......

Page 96: ...Fig 105 Gear Tooth Contact Patterns 3 60 TUBE 181 AND 186 FBI AXLE XJ ADJUSTMENTS Continued...

Page 100: ...Installer D 144 Installer W 262 3 64 TUBE 181 AND 186 FBI AXLE XJ SPECIAL TOOLS Continued...

Page 134: ...Fig 79 Gear Tooth Contact Patterns 3 98 194 RBI AXLE XJ ADJUSTMENTS Continued...

Page 166: ...Fig 59 Gear Tooth Contact Patterns 3 130 8 1 4 REAR AXLE XJ ADJUSTMENTS Continued...

Page 215: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Page 226: ......

Page 231: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Page 242: ......

Page 284: ......

Page 300: ......

Page 372: ......

Page 376: ......

Page 382: ......

Page 404: ......

Page 412: ......

Page 416: ......

Page 430: ......

Page 444: ......

Page 448: ......

Page 468: ......

Page 482: ......

Page 500: ......

Page 508: ......

Page 520: ......

Page 526: ......

Page 532: ......

Page 540: ......

Page 550: ......

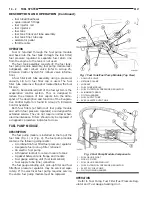

Page 647: ...Fig 16 2 5L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 23 DESCRIPTION AND OPERATION Continued...

Page 648: ...Fig 17 4 0L Engine 8W 90 24 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Page 649: ...Fig 18 4 0L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 25 DESCRIPTION AND OPERATION Continued...

Page 662: ...Fig 31 Liftgate 8W 90 38 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Page 666: ......

Page 810: ......

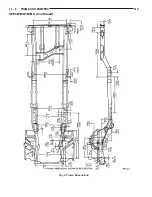

Page 826: ...Fig 6 Frame Dimensions 13 8 FRAME AND BUMPERS XJ SPECIFICATIONS Continued...

Page 828: ......

Page 1316: ......

Page 1328: ......

Page 1353: ...Fig 3 Hood Components XJ BODY 23 25 REMOVAL AND INSTALLATION Continued...

Page 1396: ...WELD LOCATIONS UPPER COWL 23 68 BODY XJ SPECIFICATIONS Continued...

Page 1397: ...UPPER COWL XJ BODY 23 69 SPECIFICATIONS Continued...

Page 1398: ...COWL 23 70 BODY XJ SPECIFICATIONS Continued...

Page 1399: ...A PILLAR XJ BODY 23 71 SPECIFICATIONS Continued...

Page 1400: ...A PILLAR 23 72 BODY XJ SPECIFICATIONS Continued...

Page 1401: ...A PILLAR XJ BODY 23 73 SPECIFICATIONS Continued...

Page 1402: ...A PILLAR 23 74 BODY XJ SPECIFICATIONS Continued...

Page 1403: ...B PILLAR XJ BODY 23 75 SPECIFICATIONS Continued...

Page 1404: ...D PILLAR 23 76 BODY XJ SPECIFICATIONS Continued...

Page 1405: ...FUEL FILLER OPENING XJ BODY 23 77 SPECIFICATIONS Continued...

Page 1406: ...CARGO AREA FLOOR PAN 23 78 BODY XJ SPECIFICATIONS Continued...

Page 1407: ...ROOF AND D PILLAR XJ BODY 23 79 SPECIFICATIONS Continued...

Page 1408: ...LIFTGATE OPENING 23 80 BODY XJ SPECIFICATIONS Continued...

Page 1409: ...ROOF XJ BODY 23 81 SPECIFICATIONS Continued...

Page 1410: ...ROOF 23 82 BODY XJ SPECIFICATIONS Continued...

Page 1411: ...FRAME RAIL XJ BODY 23 83 SPECIFICATIONS Continued...

Page 1412: ...FRAME RAIL 23 84 BODY XJ SPECIFICATIONS Continued...

Page 1413: ...FRAME RAIL XJ BODY 23 85 SPECIFICATIONS Continued...

Page 1414: ...FRAME RAIL 23 86 BODY XJ SPECIFICATIONS Continued...

Page 1415: ...REINFORCEMENT XJ BODY 23 87 SPECIFICATIONS Continued...

Page 1416: ...FRONT INNER FENDER 23 88 BODY XJ SPECIFICATIONS Continued...

Page 1417: ...FRONT INNER FENDER AND RADIATOR CLOSURE PANEL XJ BODY 23 89 SPECIFICATIONS Continued...

Page 1418: ...REINFORCEMENT 23 90 BODY XJ SPECIFICATIONS Continued...

Page 1419: ...FRONT FENDER XJ BODY 23 91 SPECIFICATIONS Continued...

Page 1420: ...BODY SIDE 23 92 BODY XJ SPECIFICATIONS Continued...

Page 1421: ...REAR WHEELHOUSE XJ BODY 23 93 SPECIFICATIONS Continued...

Page 1422: ...REAR INNER WHEELHOUSE 23 94 BODY XJ SPECIFICATIONS Continued...

Page 1423: ...BODY SIDE XJ BODY 23 95 SPECIFICATIONS Continued...

Page 1424: ...BODY SIDE 23 96 BODY XJ SPECIFICATIONS Continued...

Page 1425: ...BODY SIDE XJ BODY 23 97 SPECIFICATIONS Continued...

Page 1426: ...BODY SIDE 23 98 BODY XJ SPECIFICATIONS Continued...

Page 1427: ...BODY SIDE XJ BODY 23 99 SPECIFICATIONS Continued...

Page 1428: ...BODY SIDE 23 100 BODY XJ SPECIFICATIONS Continued...

Page 1429: ...UNDERBODY XJ BODY 23 101 SPECIFICATIONS Continued...

Page 1430: ...UNDERBODY 23 102 BODY XJ SPECIFICATIONS Continued...

Page 1431: ...UNDERBODY XJ BODY 23 103 SPECIFICATIONS Continued...

Page 1432: ...UNDERBODY 23 104 BODY XJ SPECIFICATIONS Continued...

Page 1433: ...UNDERBODY XJ BODY 23 105 SPECIFICATIONS Continued...

Page 1434: ...UNDERBODY 23 106 BODY XJ SPECIFICATIONS Continued...

Page 1435: ...UNDERBODY XJ BODY 23 107 SPECIFICATIONS Continued...

Page 1436: ...UNDERBODY 23 108 BODY XJ SPECIFICATIONS Continued...

Page 1437: ...UNDERBODY XJ BODY 23 109 SPECIFICATIONS Continued...

Page 1438: ...UNDERBODY 23 110 BODY XJ SPECIFICATIONS Continued...

Page 1439: ...UNDERBODY XJ BODY 23 111 SPECIFICATIONS Continued...

Page 1440: ...BODY SEALING LOCATIONS APPLICATION METHODS 23 112 BODY XJ SPECIFICATIONS Continued...

Page 1441: ...COWL AND DASH PANEL XJ BODY 23 113 SPECIFICATIONS Continued...

Page 1442: ...DASH PANEL AND FLOOR PAN 23 114 BODY XJ SPECIFICATIONS Continued...

Page 1443: ...FLOOR PAN XJ BODY 23 115 SPECIFICATIONS Continued...

Page 1444: ...REAR INNER WHEELHOUSE 23 116 BODY XJ SPECIFICATIONS Continued...

Page 1445: ...FRONT INNER WHEELHOUSE XJ BODY 23 117 SPECIFICATIONS Continued...

Page 1446: ...BODY SIDE 23 118 BODY XJ SPECIFICATIONS Continued...

Page 1447: ...BODY SIDE XJ BODY 23 119 SPECIFICATIONS Continued...

Page 1448: ...BODY SIDE 23 120 BODY XJ SPECIFICATIONS Continued...

Page 1449: ...ROOF PANEL XJ BODY 23 121 SPECIFICATIONS Continued...

Page 1450: ...FUEL FILLER HOUSING 23 122 BODY XJ SPECIFICATIONS Continued...

Page 1451: ...LIFTGATE OPENING XJ BODY 23 123 SPECIFICATIONS Continued...

Page 1452: ...STRUCTURAL ADHESIVE LOCATIONS LEFT QUARTER PANEL 23 124 BODY XJ SPECIFICATIONS Continued...

Page 1453: ...REAR WHEELHOUSE XJ BODY 23 125 SPECIFICATIONS Continued...

Page 1454: ...ROOF BOWS 23 126 BODY XJ SPECIFICATIONS Continued...

Page 1464: ......

Page 1512: ......

Page 1528: ......