FUEL PUMP

DESCRIPTION

The fuel pump is located inside of the fuel pump

module. A 12 volt, permanent magnet, electric motor

powers the fuel pump.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation: The pump outlet con-

tains a one-way check valve to prevent fuel flow back

into the tank and to maintain fuel supply line pres-

sure (engine warm) when pump is not operational. It

is also used to keep the fuel supply line full of gaso-

line when pump is not operational. After the vehicle

has cooled down, fuel pressure may drop to 0 psi

(cold fluid contracts), but liquid gasoline will remain

in fuel supply line between the check valve and fuel

injectors. Fuel pressure that has dropped to 0

psi on a cooled down vehicle (engine off) is a

normal condition. Refer to the Fuel Pressure Leak

Down Test for more information.

FUEL GAUGE SENDING UNIT

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation: A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM). NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-

fied with the circuit opened (fuel pump module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about.6 volts at FULL, to about 8.6 volts at

EMPTY (about 8.6 volts at EMPTY for Jeep

models, and about 7.0 volts at EMPTY for

Dodge Truck models). The resistor track is used to

vary the voltage (resistance) depending on fuel tank

float level. As fuel level increases, the float and arm

move up, which decreases voltage. As fuel level

decreases, the float and arm move down, which

increases

voltage.

The

varied

voltage

signal

is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

FUEL FILTER/FUEL PRESSURE REGULATOR

DESCRIPTION

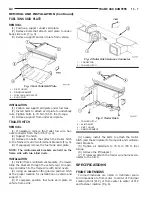

The combination fuel filter and fuel pressure regu-

lator is located on the top of fuel pump module (Fig.

1).

OPERATION

A combination fuel filter and fuel pressure regula-

tor is used on all engines. A separate frame mounted

fuel filter is not used with any engine.

Fuel Pressure Regulator Operation: The pres-

sure regulator is a mechanical device that is not con-

trolled by engine vacuum or the Powertrain Control

Module (PCM).

The regulator is calibrated to maintain fuel system

operating pressure of approximately 339 kPa

6

34

kPa (49.2 psi

6

5 psi) at the fuel injectors. It con-

tains a diaphragm, calibrated springs and a fuel

return valve. The internal fuel filter is also part of

the assembly.

Fuel is supplied to the filter/regulator by the elec-

tric fuel pump through an opening tube at the bot-

tom of filter/regulator (Fig. 3).

The regulator acts as a check valve to maintain

some fuel pressure when the engine is not operating.

This will help to start the engine. A second check

valve is located at the outlet end of the electric fuel

pump. Refer to Fuel Pump—Description and

XJ

FUEL SYSTEM

14 - 3

DESCRIPTION AND OPERATION (Continued)

Summary of Contents for Cherokee 2000

Page 4: ......

Page 36: ......

Page 96: ...Fig 105 Gear Tooth Contact Patterns 3 60 TUBE 181 AND 186 FBI AXLE XJ ADJUSTMENTS Continued...

Page 100: ...Installer D 144 Installer W 262 3 64 TUBE 181 AND 186 FBI AXLE XJ SPECIAL TOOLS Continued...

Page 134: ...Fig 79 Gear Tooth Contact Patterns 3 98 194 RBI AXLE XJ ADJUSTMENTS Continued...

Page 166: ...Fig 59 Gear Tooth Contact Patterns 3 130 8 1 4 REAR AXLE XJ ADJUSTMENTS Continued...

Page 215: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Page 226: ......

Page 231: ...Fig 8 Clutch Components And Inspection XJ CLUTCH 6 5 DIAGNOSIS AND TESTING Continued...

Page 242: ......

Page 284: ......

Page 300: ......

Page 372: ......

Page 376: ......

Page 382: ......

Page 404: ......

Page 412: ......

Page 416: ......

Page 430: ......

Page 444: ......

Page 448: ......

Page 468: ......

Page 482: ......

Page 500: ......

Page 508: ......

Page 520: ......

Page 526: ......

Page 532: ......

Page 540: ......

Page 550: ......

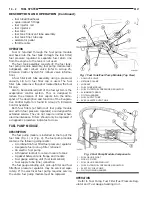

Page 647: ...Fig 16 2 5L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 23 DESCRIPTION AND OPERATION Continued...

Page 648: ...Fig 17 4 0L Engine 8W 90 24 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Page 649: ...Fig 18 4 0L Engine XJ 8W 90 CONNECTOR LOCATIONS 8W 90 25 DESCRIPTION AND OPERATION Continued...

Page 662: ...Fig 31 Liftgate 8W 90 38 8W 90 CONNECTOR LOCATIONS XJ DESCRIPTION AND OPERATION Continued...

Page 666: ......

Page 810: ......

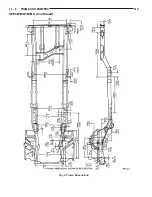

Page 826: ...Fig 6 Frame Dimensions 13 8 FRAME AND BUMPERS XJ SPECIFICATIONS Continued...

Page 828: ......

Page 1316: ......

Page 1328: ......

Page 1353: ...Fig 3 Hood Components XJ BODY 23 25 REMOVAL AND INSTALLATION Continued...

Page 1396: ...WELD LOCATIONS UPPER COWL 23 68 BODY XJ SPECIFICATIONS Continued...

Page 1397: ...UPPER COWL XJ BODY 23 69 SPECIFICATIONS Continued...

Page 1398: ...COWL 23 70 BODY XJ SPECIFICATIONS Continued...

Page 1399: ...A PILLAR XJ BODY 23 71 SPECIFICATIONS Continued...

Page 1400: ...A PILLAR 23 72 BODY XJ SPECIFICATIONS Continued...

Page 1401: ...A PILLAR XJ BODY 23 73 SPECIFICATIONS Continued...

Page 1402: ...A PILLAR 23 74 BODY XJ SPECIFICATIONS Continued...

Page 1403: ...B PILLAR XJ BODY 23 75 SPECIFICATIONS Continued...

Page 1404: ...D PILLAR 23 76 BODY XJ SPECIFICATIONS Continued...

Page 1405: ...FUEL FILLER OPENING XJ BODY 23 77 SPECIFICATIONS Continued...

Page 1406: ...CARGO AREA FLOOR PAN 23 78 BODY XJ SPECIFICATIONS Continued...

Page 1407: ...ROOF AND D PILLAR XJ BODY 23 79 SPECIFICATIONS Continued...

Page 1408: ...LIFTGATE OPENING 23 80 BODY XJ SPECIFICATIONS Continued...

Page 1409: ...ROOF XJ BODY 23 81 SPECIFICATIONS Continued...

Page 1410: ...ROOF 23 82 BODY XJ SPECIFICATIONS Continued...

Page 1411: ...FRAME RAIL XJ BODY 23 83 SPECIFICATIONS Continued...

Page 1412: ...FRAME RAIL 23 84 BODY XJ SPECIFICATIONS Continued...

Page 1413: ...FRAME RAIL XJ BODY 23 85 SPECIFICATIONS Continued...

Page 1414: ...FRAME RAIL 23 86 BODY XJ SPECIFICATIONS Continued...

Page 1415: ...REINFORCEMENT XJ BODY 23 87 SPECIFICATIONS Continued...

Page 1416: ...FRONT INNER FENDER 23 88 BODY XJ SPECIFICATIONS Continued...

Page 1417: ...FRONT INNER FENDER AND RADIATOR CLOSURE PANEL XJ BODY 23 89 SPECIFICATIONS Continued...

Page 1418: ...REINFORCEMENT 23 90 BODY XJ SPECIFICATIONS Continued...

Page 1419: ...FRONT FENDER XJ BODY 23 91 SPECIFICATIONS Continued...

Page 1420: ...BODY SIDE 23 92 BODY XJ SPECIFICATIONS Continued...

Page 1421: ...REAR WHEELHOUSE XJ BODY 23 93 SPECIFICATIONS Continued...

Page 1422: ...REAR INNER WHEELHOUSE 23 94 BODY XJ SPECIFICATIONS Continued...

Page 1423: ...BODY SIDE XJ BODY 23 95 SPECIFICATIONS Continued...

Page 1424: ...BODY SIDE 23 96 BODY XJ SPECIFICATIONS Continued...

Page 1425: ...BODY SIDE XJ BODY 23 97 SPECIFICATIONS Continued...

Page 1426: ...BODY SIDE 23 98 BODY XJ SPECIFICATIONS Continued...

Page 1427: ...BODY SIDE XJ BODY 23 99 SPECIFICATIONS Continued...

Page 1428: ...BODY SIDE 23 100 BODY XJ SPECIFICATIONS Continued...

Page 1429: ...UNDERBODY XJ BODY 23 101 SPECIFICATIONS Continued...

Page 1430: ...UNDERBODY 23 102 BODY XJ SPECIFICATIONS Continued...

Page 1431: ...UNDERBODY XJ BODY 23 103 SPECIFICATIONS Continued...

Page 1432: ...UNDERBODY 23 104 BODY XJ SPECIFICATIONS Continued...

Page 1433: ...UNDERBODY XJ BODY 23 105 SPECIFICATIONS Continued...

Page 1434: ...UNDERBODY 23 106 BODY XJ SPECIFICATIONS Continued...

Page 1435: ...UNDERBODY XJ BODY 23 107 SPECIFICATIONS Continued...

Page 1436: ...UNDERBODY 23 108 BODY XJ SPECIFICATIONS Continued...

Page 1437: ...UNDERBODY XJ BODY 23 109 SPECIFICATIONS Continued...

Page 1438: ...UNDERBODY 23 110 BODY XJ SPECIFICATIONS Continued...

Page 1439: ...UNDERBODY XJ BODY 23 111 SPECIFICATIONS Continued...

Page 1440: ...BODY SEALING LOCATIONS APPLICATION METHODS 23 112 BODY XJ SPECIFICATIONS Continued...

Page 1441: ...COWL AND DASH PANEL XJ BODY 23 113 SPECIFICATIONS Continued...

Page 1442: ...DASH PANEL AND FLOOR PAN 23 114 BODY XJ SPECIFICATIONS Continued...

Page 1443: ...FLOOR PAN XJ BODY 23 115 SPECIFICATIONS Continued...

Page 1444: ...REAR INNER WHEELHOUSE 23 116 BODY XJ SPECIFICATIONS Continued...

Page 1445: ...FRONT INNER WHEELHOUSE XJ BODY 23 117 SPECIFICATIONS Continued...

Page 1446: ...BODY SIDE 23 118 BODY XJ SPECIFICATIONS Continued...

Page 1447: ...BODY SIDE XJ BODY 23 119 SPECIFICATIONS Continued...

Page 1448: ...BODY SIDE 23 120 BODY XJ SPECIFICATIONS Continued...

Page 1449: ...ROOF PANEL XJ BODY 23 121 SPECIFICATIONS Continued...

Page 1450: ...FUEL FILLER HOUSING 23 122 BODY XJ SPECIFICATIONS Continued...

Page 1451: ...LIFTGATE OPENING XJ BODY 23 123 SPECIFICATIONS Continued...

Page 1452: ...STRUCTURAL ADHESIVE LOCATIONS LEFT QUARTER PANEL 23 124 BODY XJ SPECIFICATIONS Continued...

Page 1453: ...REAR WHEELHOUSE XJ BODY 23 125 SPECIFICATIONS Continued...

Page 1454: ...ROOF BOWS 23 126 BODY XJ SPECIFICATIONS Continued...

Page 1464: ......

Page 1512: ......

Page 1528: ......