SERVICE MANUAL FOR SXG323&326

14

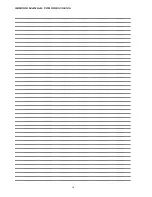

4. PERIODIC INSPECTION TABLE

c

:Inspection, replenishment, and adjustment

U

:Cleaning and washing

z

:Replacement

:Consult your dealer.

Check points

Pre-

operation

Inspection and servicing intervals

hours of operation

Intervals after that

Judgement criteria

50 100 150 200 250 300 350 400

Engine oil

c

z

z

Replace after initial 50 h

and then every 100 h.

Maintain the specified level.

Air cleaner

U

U

U

U

U

U

U

U

Clean after every 50h.

Engine coolant

c

Replace every year.

Maintain the specified level.

Fuel

c

Keep fuel tank always full.

Fuel strainer

c

U

U

z

U

Clean after every 100h.

Replace element after

every 300h.

There should be no dust or

water in filter.

Fan belt

c

13.8~14.8mm

(0.54~0.58 in.) deflection

Electrolyte level

c

c

c

c

c

c

c

c

Inspect after every 50h.

Level should be kept properly.

Engine oil filter

Replace after initial 50h.

Replace after every 300h.

Transmission oil

c

Replace after initial 50h

and then after every 200h.

Maintain the specified level.

Hydraulic oil filter

Replace after initial 50h.

and then replace after every 200h.

Suction filter

Clean after initial 50h.

and then replace after every 200h.

Chain case

Replace after initial 50h

and then after every 200h.

maintain the specified level

Brake pedal play

c

20 to 30 mm (0.8 to 1.2h.)

Steering wheel

c

Check after every 300h.

There should be no abnormality.

Ball joints of steering

system linkage

c

Check after every 300h.

Loose ball joints should be

re-tightened.

Tire pressure

c

SXG326

Front: 1.5 x 10

5

Pa (22psi)

Rear: 1.4 x 10

5

Pa (20psi)

SXG323

Front: 1.4 x 10

5

Pa (20psi)

Rear: 1.9 x 10

5

Pa (28psi)

Toe-in

Adjust after every 300h.

1 to 5mm(0.04 to 0.20in.)

Wheel tightening nuts

c

There should be no loose nuts.

Grease-up

c

c

c

c

c

c

c

c

Inject grease after every 50h.

Radiator screen

U

There should be no clogging.

Radiator

U

There should be no clogging.

Electrical apparatus

c

All should work properly.

Safety switches

c

All should work properly.

Air intake openings

U

All should work properly.

Bolts and nuts

c

There should be no loose ones.

Rubber pipes

c

c

c

c

Check after every 100h.

IMPORTANT: • Above mentioned service intervals should be used as reference creteria. If working conditions are

harder, earlier service is recommended.

• When special technology and special tools are required, consult your dealer.

Summary of Contents for SXG323

Page 1: ...LAWN MOWERS MOWER DECKS COLLECTORS SCMB48 SCMA54 SBC550X 600X ...

Page 5: ......

Page 11: ...SERVICE MANUAL FOR SXG323 326 10 ...

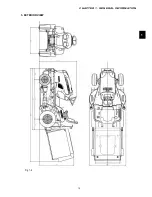

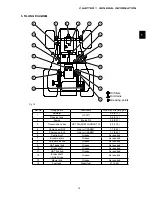

Page 14: ...CHAPTER 1 GENERAL INFORMATION 13 1 3 EXTERIOR VIEW Fig 1 4 ...

Page 17: ...SERVICE MANUAL FOR SXG323 326 16 ...

Page 33: ...SERVICE MANUAL FOR SXG323 326 32 ...

Page 51: ...SERVICE MANUAL FOR SXG323 326 50 3 3 CYLINDER BLOCK 3 3 1 EXPLODED VIEW Fig 4 55 ...

Page 67: ...SERVICE MANUAL FOR SXG323 326 66 ...

Page 70: ...CHAPTER 5 LUBRICATION SYSTEM 69 5 1 4 EXPLODED VIEW OF OIL PUMP Fig 5 4 ...

Page 73: ...SERVICE MANUAL FOR SXG323 326 72 ...

Page 89: ...SERVICE MANUAL FOR SXG323 326 88 42 3 33 Fig 8 3 2 2 7 2 6 3 TYPE Fig 8 4 ...

Page 93: ...SERVICE MANUAL FOR SXG323 326 92 ...

Page 97: ...SERVICE MANUAL FOR SXG323 326 96 2 OPERATING DIAGRAM OF HST Fig 10 2 ...

Page 99: ...SERVICE MANUAL FOR SXG323 326 98 Fig 10 5 Fig 10 6 ...

Page 100: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 99 10 Fig 10 7 ...

Page 101: ...SERVICE MANUAL FOR SXG323 326 100 Fig 10 8 4 DISASSEMBLY AND REASSEMBLY ...

Page 102: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 101 10 4 3 ...

Page 103: ...SERVICE MANUAL FOR SXG323 326 102 ...

Page 107: ...SERVICE MANUAL FOR SXG323 326 106 4 5 CRITERIA FOR REPLACING WORN PARTS ...

Page 117: ...SERVICE MANUAL FOR SXG323 326 116 ...

Page 124: ...CHAPTER 12 POWER STEERING SYSTEM 123 12 3 MAJOR TROUBLES AND CAUSES AND COUNTERMEASURES ...

Page 125: ...SERVICE MANUAL FOR SXG323 326 124 ...

Page 126: ...CHAPTER 12 POWER STEERING SYSTEM 125 12 ...

Page 127: ...SERVICE MANUAL FOR SXG323 326 126 ...

Page 130: ...CHAPTER 13 ELECTRICAL ACCESSORIES 129 13 2 WIRING DIAGRAM E TYPE Fig 13 12 ...

Page 131: ...SERVICE MANUAL FOR SXG323 326 130 3 WIRING DIAGRAM GE TYPE Fig 13 13 ...

Page 132: ...CHAPTER 13 ELECTRICAL ACCESSORIES 131 13 Fig 13 14 4 STARTER ...

Page 140: ...CHAPTER 13 ELECTRICAL ACCESSORIES 139 13 Fig 13 48 Fig 13 47 ...

Page 149: ......

Page 151: ...SERVICE MANUAL FOR SXG323 326 4 ...

Page 152: ...CHAPTER 1 FOR SAFETY LABELS 5 1 SAFETY LABELS SCMB48 54 CHAPTER 1 FOR SAFETY LABELS ...

Page 163: ...SERVICE MANUAL FOR SXG323 326 16 ...

Page 171: ...SERVICE MANUAL FOR SXG323 326 24 ...

Page 173: ...SERVICE MANUAL FOR SXG323 326 26 3 Gear box left hand ...

Page 175: ...SERVICE MANUAL FOR SXG323 326 28 SCMB48 54 Front Belt and Belt tension Blade and Blade hub ...

Page 183: ......

Page 185: ...SERVICE MANUAL FOR SXG323 326 4 ...

Page 188: ...CHAPTER 2 SPECIFICATIONS 7 2 SPECIFICATIONS CHAPTER 2 SPECIFICATIONS ...

Page 189: ...SERVICE MANUAL FOR SXG323 326 8 ...

Page 191: ...SERVICE MANUAL FOR SXG323 326 10 ...

Page 195: ...SERVICE MANUAL FOR SXG323 326 14 ...

Page 227: ...SERVICE MANUAL FOR SXG323 326 46 ...

Page 229: ...SERVICE MANUAL FOR SXG323 326 48 ...