CHAPTER 4. ENGINE

61

4

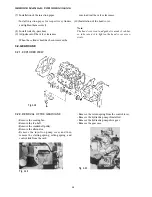

(4) Then install bearing cap seals (B). Drive them in

until they subside 0 - 0.3 mm (0 - 0.012 in.) from

the cylinder block end. Fill the gaps with sili-

cone compound. Tighten the journal bearing cap

to the specified torque.

Fig. 4-95

3.3.7. INSTALLATION OF PISTON/CON-NECT-

ING-ROD ASSEMBLIES

• Install bearings on the connecting-rod big end

and bearing cap with the bearing projections

seated securely in respective notches in the big

end and bearing cap. Apply engine oil to the

bearing surfaces.

• Clean the cylinder bores and crankshaft, and

apply engine oil to them.

• Set the crankshaft at BDC.

• Turn the front mark on the piston head towards

the front and make sure that the piston ring gaps

are 120

°

apart from each other. Then insert the

piston/connecting rod assembly, compressing the

piston rings with a piston ring compressor, into

the cylinder until the connecting rod bearing

comes into contact with the crankpin.

Fig.4-96

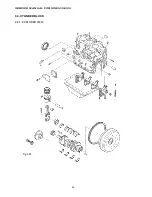

• Install the connecting rod bearing cap having the

same number that the connecting rod has.

Fig. 4-97

• Tighten the connecting rod bearing cap to the

specified torque.

Fig. 4-98

The crankshaft should turn smoothly.

Specified torque:

4.5 - 5.5 kgf

・

m

Specified torque:

2.7 - 3.3 kgf

・

m

Summary of Contents for SXG323

Page 1: ...LAWN MOWERS MOWER DECKS COLLECTORS SCMB48 SCMA54 SBC550X 600X ...

Page 5: ......

Page 11: ...SERVICE MANUAL FOR SXG323 326 10 ...

Page 14: ...CHAPTER 1 GENERAL INFORMATION 13 1 3 EXTERIOR VIEW Fig 1 4 ...

Page 17: ...SERVICE MANUAL FOR SXG323 326 16 ...

Page 33: ...SERVICE MANUAL FOR SXG323 326 32 ...

Page 51: ...SERVICE MANUAL FOR SXG323 326 50 3 3 CYLINDER BLOCK 3 3 1 EXPLODED VIEW Fig 4 55 ...

Page 67: ...SERVICE MANUAL FOR SXG323 326 66 ...

Page 70: ...CHAPTER 5 LUBRICATION SYSTEM 69 5 1 4 EXPLODED VIEW OF OIL PUMP Fig 5 4 ...

Page 73: ...SERVICE MANUAL FOR SXG323 326 72 ...

Page 89: ...SERVICE MANUAL FOR SXG323 326 88 42 3 33 Fig 8 3 2 2 7 2 6 3 TYPE Fig 8 4 ...

Page 93: ...SERVICE MANUAL FOR SXG323 326 92 ...

Page 97: ...SERVICE MANUAL FOR SXG323 326 96 2 OPERATING DIAGRAM OF HST Fig 10 2 ...

Page 99: ...SERVICE MANUAL FOR SXG323 326 98 Fig 10 5 Fig 10 6 ...

Page 100: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 99 10 Fig 10 7 ...

Page 101: ...SERVICE MANUAL FOR SXG323 326 100 Fig 10 8 4 DISASSEMBLY AND REASSEMBLY ...

Page 102: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 101 10 4 3 ...

Page 103: ...SERVICE MANUAL FOR SXG323 326 102 ...

Page 107: ...SERVICE MANUAL FOR SXG323 326 106 4 5 CRITERIA FOR REPLACING WORN PARTS ...

Page 117: ...SERVICE MANUAL FOR SXG323 326 116 ...

Page 124: ...CHAPTER 12 POWER STEERING SYSTEM 123 12 3 MAJOR TROUBLES AND CAUSES AND COUNTERMEASURES ...

Page 125: ...SERVICE MANUAL FOR SXG323 326 124 ...

Page 126: ...CHAPTER 12 POWER STEERING SYSTEM 125 12 ...

Page 127: ...SERVICE MANUAL FOR SXG323 326 126 ...

Page 130: ...CHAPTER 13 ELECTRICAL ACCESSORIES 129 13 2 WIRING DIAGRAM E TYPE Fig 13 12 ...

Page 131: ...SERVICE MANUAL FOR SXG323 326 130 3 WIRING DIAGRAM GE TYPE Fig 13 13 ...

Page 132: ...CHAPTER 13 ELECTRICAL ACCESSORIES 131 13 Fig 13 14 4 STARTER ...

Page 140: ...CHAPTER 13 ELECTRICAL ACCESSORIES 139 13 Fig 13 48 Fig 13 47 ...

Page 149: ......

Page 151: ...SERVICE MANUAL FOR SXG323 326 4 ...

Page 152: ...CHAPTER 1 FOR SAFETY LABELS 5 1 SAFETY LABELS SCMB48 54 CHAPTER 1 FOR SAFETY LABELS ...

Page 163: ...SERVICE MANUAL FOR SXG323 326 16 ...

Page 171: ...SERVICE MANUAL FOR SXG323 326 24 ...

Page 173: ...SERVICE MANUAL FOR SXG323 326 26 3 Gear box left hand ...

Page 175: ...SERVICE MANUAL FOR SXG323 326 28 SCMB48 54 Front Belt and Belt tension Blade and Blade hub ...

Page 183: ......

Page 185: ...SERVICE MANUAL FOR SXG323 326 4 ...

Page 188: ...CHAPTER 2 SPECIFICATIONS 7 2 SPECIFICATIONS CHAPTER 2 SPECIFICATIONS ...

Page 189: ...SERVICE MANUAL FOR SXG323 326 8 ...

Page 191: ...SERVICE MANUAL FOR SXG323 326 10 ...

Page 195: ...SERVICE MANUAL FOR SXG323 326 14 ...

Page 227: ...SERVICE MANUAL FOR SXG323 326 46 ...

Page 229: ...SERVICE MANUAL FOR SXG323 326 48 ...