11

MASONRY 500

IMER INTERNATIONAL S.p.A.

GB

GB

15.3.1 CUTTING WITH CUTTING WHEEL LOWERED

FROM ABOVE.

Adjust the vertical height by turning the crank (ref.11, fig.1),

position the piece to be cut, start the panel saw and commence

cutting operations by pressing the pedal (ref.16, fig.1) to lower

the wheel from above.

15.3.2 BLADE CHANGE

To change the blade refer to section 14.

16. USING 550 DIAMETER CUTTING WHEEL.

If an optional cutting wheel diameter 550 mm is used instead of

the standard wheel diameter 500 mm, it is important that the

stop bolt be calibrated to prevent interference between the

wheel and the carriage when the head is in the lowest position.

- Warning. The panel saw is fitted with a stop bolt to

stop the cutting wheel in the lowest vertical position.

This stop is calibrated for a 500 mm cutting wheel. If

you are using a 550 mm cutting wheel, loosen the bolt

(ref. 17, fig. 1), lower the wheel to the lowest position, by

turning the crank, then check, with the motor turned

off, that there is no interference between the cutting

wheel and the piece holder carriage when the pedal is

pressed. Adjust the bolt, bring it into contact with the

stop and tighten the lock nut.

- Note that the blade must have an external diameter

of 550 mm, a central hole diameter of 25.4 mm and max.

thickness of 3 mm.

17. MAINTENANCE

- WARNING! Servicing must always be carried out by

qualified technicians and only after the motor has been

switched off.

- Always keep the guards in proper working order

and free from damage.Take particular care to ensure

that the blade guards are kept efficient and clean,

replacing them if they are damaged

- As there is the continuous risk of inadvertent

damage to the electric cables, these must be checked

regularly each time before the machine is used.

Do not leave the machine outside: it must always be protected

from the weather.

Below is a list of the cleaning operations that must be carried

out at the end of every shift.

17.1 TANK CLEANING

Empty the tank by removing the drain plug. Remove cutting

residue using a jet of water.

17.2 TANK REMOVAL (Ref.Fig.7).

Empty the drum opening the drum cap from right or left side.

17.3 WORK SURFACE CLEANING

Always keep work surfaces clean. Residual dirt can impair

cutting precision.

17.4 GUIDE RAIL CLEANING

It is good practice to remove all traces of dirt from the guides.

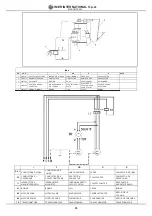

17.5 CLEANING AND MAINTENANCE OF COOLING CIRCUIT

- If water does not reach the blade stop the machine immediately to

avoid blade damage.

- After switching off the machine ensure that the water level is sufficient.

– Check that there is water in the pump by unscrewing the connector,

and if necessary top up until water flows out (fig.10).

- WARNING. Before starting the panel saw for the first

time, or when starting it after long periods of inactivity, fill

the pump with water as described above

- At the end of every shift, unscrew the suction hose filter and clean

it. Then, circulate some water through it placing inside a bucket of

clean water.

17.5 CLEANING AND MAINTENANCE OF COOLING

CIRCUIT

- If water does not reach the blade stop the machine immediately

to avoid blade damage.

- After switching off the machine ensure that the water level is

sufficient.

- If necessary, after disconnecting the machine from the power

supply check that the tap, hose and pump filter are not blocked

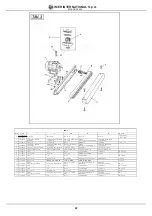

17.6 TENSIONING THE DRIVE BELT (fig. 8)

- Switch off the electric motor and remove the plug from the

power supply.

- Unscrew the 4 screws that secure the movable belt guard

(ref. 1).

- Loosen the 4 (ref. 2) screws that clamp the electric motor to

the blade support.

- Tension the belt using the nut (ref. 3): apply a force of about

F=6 Kg to the centre of the free section of the belt, the arrow

should be about f=6 mm (fig. 9).

- Tighten the screws on the electric motor, checking the alignment

of the motor pulley and the blade pulley

- Refit the guard and lock it using the 4 screws.

- To avoid shortening the life of the belt, the bearings

and the blade shaft, do not overtension the belt. Finally,

check the two pulleys are aligned

17.7 DRIVE BELT REPLACEMENT

Repeat the operations described in section 17.6, replacing the

belt before tensioning it.

17.8 ENDOTHERMIC ENGINE MAINTENANCE

Refer to the specific instruction manual enclosed with the

endothermic engine for its correct routine maintenance.

17.9 REPAIRS

- Do not start the saw during repair work.

Only use genuine IMER spare parts and do not modify them.

- If the guards are removed to carry out repairs, they

must be refitted properly when the repair work is finished.

18. TROUBLESHOOTING

- WARNING! Before carrying out any maintenance

operations, switch off the machine, and remove the plug

from the power socket

FAULT

CAUSE

REMEDY

Motor does not start

when switch is

turned

- Defective power

cable

- Plug not inserted in

socket correctly

- Power cable from

plug to control panel

detached

- Loose wire inside

motor circuit board

- A wire has become

disconnected inside

the panel

- Faulty main switch

-The overload safety

device has been

activated.

- Check power cables

- Ensure correct

connection

- Connect cable- re

-Connect wire

- Remake the

connection

- Replace switch

-Wait for a few minutes

and then try restarting

the machine.

Horizontal carriage

movement not

smooth

- Guide rails dirty

- Clean the guide rails

Lack of cooling water

supply to blade

Refer to section 17.5: "cleaning and

maintenance of cooling circuit" (Chapter 17.5)

Blade does not cut

- Blade is worn

- Drive belt not

tensioned

- Fit new blade

-Tension the belt

Motor starts but

blade does not rotate

Belt is broken

Replace drive belt