This document is property of NIIGATA POWER SYSTEMS CO., LTD. It must be neither reproduced nor communicated nor published without permission.

SECTION

4

- DISASSEMBLY AND REASSEMBLY

4.3 CYLINDER LINER

4-3-01

4.3 CYLINDER LINERS

4.3.1 Description

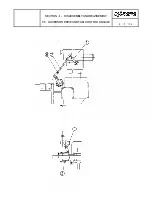

The cylinder liners are cast iron, replaceable, wet (water-cooled) liners. As

shown below, a flange at the top of each liner rests on top of the engine

block. The liners are clamped in place when the cylinder heads are bolted to

the block.

A sealing compound is used between the liner flange and the top surface of the

block. O-ring seals

③

are used on the OD of the liner to seal the water

passages in the block.

4.3.2 Visual Inspection

- After removing the cylinder head and the piston, visually inspect the

cylinder liner bore.

- If deep scratches or surface galling is apparent on the surface of the bore,

a new liner should be installed.

- Deglazing the Liner

- If the liner is to be reused, carefully check the surface of the bore in the

ring travel area. If the surface is very highly polished and no

circumferential "tool marks" are visible under a strong light, deglazing may

be required. Deglazing forms microscopic oil grooves in the liner surface

to retain an oil film and improve lubrication.

Summary of Contents for NIIGATA MG(L)26HLX

Page 2: ......

Page 34: ......

Page 38: ......

Page 40: ......

Page 60: ......

Page 66: ......

Page 68: ......

Page 80: ......

Page 82: ......

Page 86: ......

Page 88: ......

Page 94: ......

Page 107: ......

Page 108: ......

Page 110: ......

Page 130: ......

Page 132: ......

Page 170: ......

Page 174: ......

Page 186: ......

Page 188: ......

Page 192: ......