This document is property of NIIGATA POWER SYSTEMS CO., LTD. It must be neither reproduced nor communicated nor published without permission.

SECTION

4

- DISASSEMBLY AND REASSEMBLY

4.4 FUEL INJECTION VALVES AND FUEL INJECTION

PUMPS

4-4-04

- Disassembly and Inspection - Fuel Injection Valve

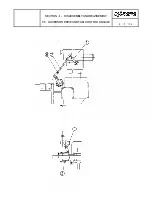

- Clamp the injection valve in a vice with the nozzle at the bottom.

- Remove the locknut

⑧

, the adjusting screw

④

, spring

⑥

, and spindle

⑦

.

- Turn the valve in the vice so the nozzle is at the top, unscrew nut

⑤

and remove the nozzle

③

.

- Carbon deposits can be removed from the nozzle tip with a soft metal brush and the nozzle

holes can be cleaned with the wire cleaners mentioned above. Needle seats can be lapped

with lube oil only - lapping compound should never be used. If lapping with oil fails

to correct a leakage problem, a new nozzle should be installed.

Reassembly

- Reinstall the nozzle with a new o-ring and torque the nut

⑤

(Refer Tightening Torque Table).

- Reinstall the spindle

⑦

, spring

⑥

, and adjusting screw

④

.

- Set the valve opening pressure, as outlined above.

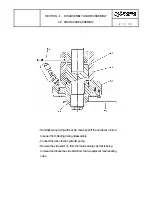

- You should clean up the surface of FV sleeve before setting the gasket on it,

and pay attention to putting the gasket

⑩

on the surface with watching

the projection of it, and please refer to the following figure.

- Insert the injection valve into the cylinder head and align the locating

mark with the corresponding mark on the cylinder head.

- Install the retainer

②

, and hand-tighten the nuts.

- Install the fuel inlet tube and union.

- Torque the injection valve nuts to 44 N

・

m.

Summary of Contents for NIIGATA MG(L)26HLX

Page 2: ......

Page 34: ......

Page 38: ......

Page 40: ......

Page 60: ......

Page 66: ......

Page 68: ......

Page 80: ......

Page 82: ......

Page 86: ......

Page 88: ......

Page 94: ......

Page 107: ......

Page 108: ......

Page 110: ......

Page 130: ......

Page 132: ......

Page 170: ......

Page 174: ......

Page 186: ......

Page 188: ......

Page 192: ......