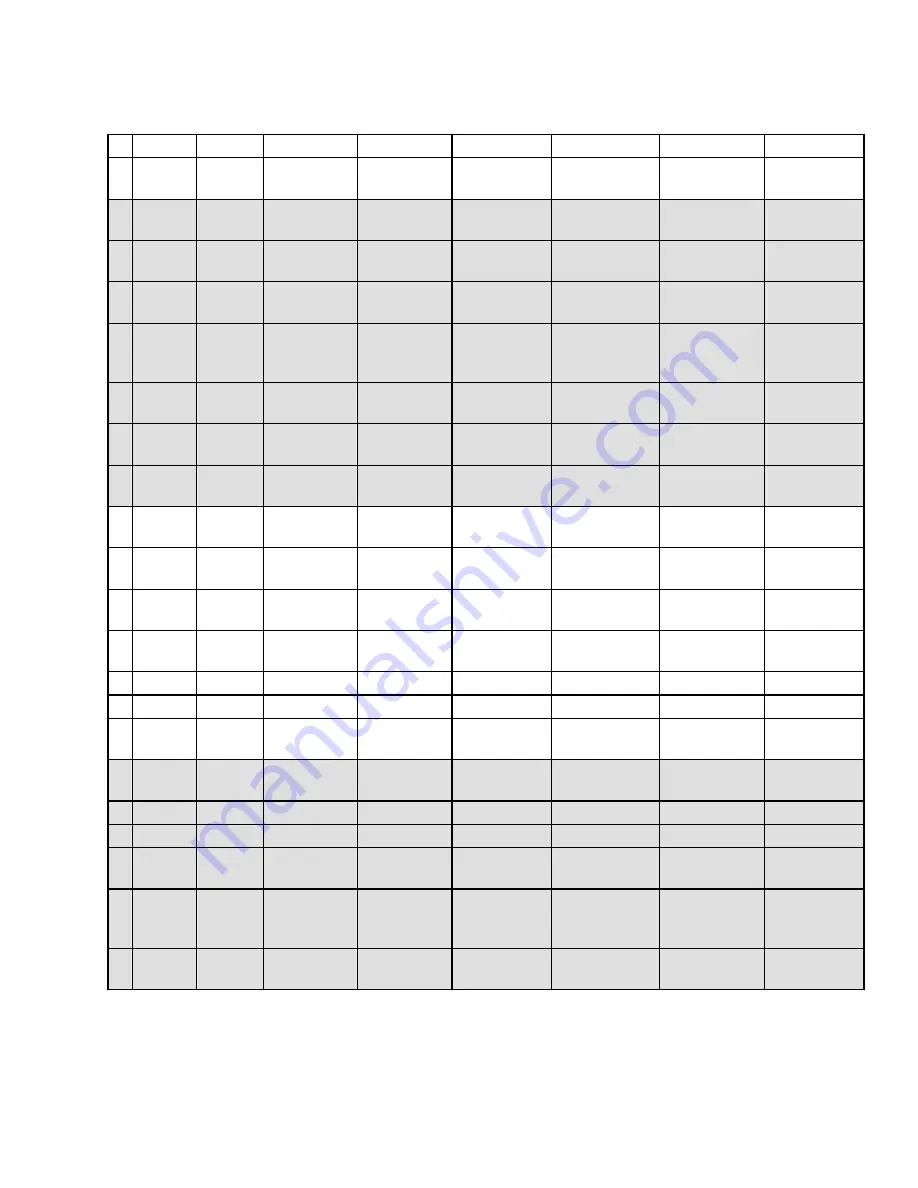

Table 1. Technician Menu Flowchart

A

B

C

D

E

F

G

H

1

Operating

Screen

Password

Entry

Activity

Log

Calibration

Diagnostics

Truck

Setup

Truck

Status

Display

Adjustment

2

Operator

Checklist

Load Weight

Fault Code Log

Add/Remove

Password

VSM Version

Set Date and Time

Format

3

Impact Events

Manual

Hydraulics

Steering Position

Sensor

Restore Default

Impact Sensor

Version

Set Units

4

Password

Steering Axle

Position

System Voltages

Rear Lights

Light Controller

Version

Set Time and Date

5

SHEET 1

Steering Wheel

Knob Center

Point

Hydraulic Sensors Optional Hydraulics

Function

Traction Motor

Controller 2 Version

Set Daylight

Saving Time

6

Valve Threshold

E-Hydraulic

Sensors

AUX 2B

Adjustments

Traction Motor

Controller 1 Version

7

Hydraulic Control

Inputs

AUX 2A

Adjustments

Pump Motor

Controller Version

8

Return to Set Tilt

Stop

Pump Status

AUX 1B

Adjustments

E-Hydraulic

Controller Version

9

Brake System

Sensors

AUX 1A

Adjustments

Hour Meters

10

Occupancy Sensor

Tilt Back

Adjustments

Truck Serial

Number

11

SHEET 2

Traction Motor 2

Status

Tilt Forward

Adjustments

Display Version

12

Traction Motor 1

Status

Lift Adjustments

13

Direction Switch

Lower Adjustments

14

Speedometer

Motion Alarm

15

Impact Monitor

Settings

16

Auto Power-Off

Time Delay

17

18

Return to Set Tilt

19

SHEET 3

Traction Speed

Limit

20

Scheduled

Maintenance

Required

21

Minimum Pump

Standby

2200 SRM 1336

Menu Flowchart

7

Summary of Contents for A1.3-1.5XNT

Page 6: ... THE QUALITY KEEPERS HYSTER APPROVED PARTS ...

Page 9: ...Figure 3 Technician Flowchart Sheet 1 of 4 2200 SRM 1336 Menu Flowchart 3 ...

Page 10: ...Figure 3 Technician Flowchart Sheet 2 of 4 Menu Flowchart 2200 SRM 1336 4 ...

Page 11: ...Figure 3 Technician Flowchart Sheet 3 of 4 2200 SRM 1336 Menu Flowchart 5 ...

Page 12: ...Figure 3 Technician Flowchart Sheet 4 of 4 Menu Flowchart 2200 SRM 1336 6 ...

Page 123: ......

Page 124: ...TECHNICAL PUBLICATIONS 2200 SRM 1336 2 14 8 13 4 13 12 12 3 12 12 11 ...