6-3

CHASSIS

FRONT AXLE

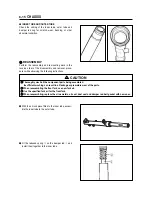

Measure the front axle runout using the dial gauge. If

the runout exceeds the limit, replace the front axle.

WHEEL

Make sure that the wheel runout (axial and radial) does

not exceed the service limit when checked as shown.

An excessive amount of runout is usually due to worn or

loose wheel bearings and can be corrected by replacing

the bearings. If bearing replacement fails to reduce the

wheel.

REASSEMBLY

Reassemble and remount the front wheel in the reverse

order of disassembly and removal, and also carry out

the following steps :

WHEEL BEARING

Apply grease to the bearing before installing.

Super grease A

Install the wheel bearings by using the special tool.

Bearing installer : 09913-75820

INSPECTION

WHEEL BEARING

Inspect the play of the wheel bearings by finger while

they are in the wheel. Rotate the inner race by finger to

inspect for abnormal noise and smooth rotation.

Replace the bearing according to in the following proce-

dure if there is anything unusual.

TIRE

For inspection of the tire : Refer to page 2-17.

Dial gauge : 09900-20606

Magnetic stand : 09900-20701

V-block : 09900-21304

Service limit

0.25 mm (0.01 in)

Axle shaft runout

Service limit

2.0 mm (0.08 in)

Wheel runout

(axial and radial)