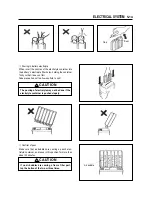

CALIPER INSPECTION

Inspect the caliper cylinder wall and piston surface for

scratch, corrosion or other damages.

If any abnormal condition is noted, replace the

caliper.Inspect the each rubber part for damage and

wear.

CALIPER REASSEMBLY

Reassemble and remount the caliper in the reverse

orders of disassembly and removal, and also carry out

the following steps.

CAUTION

Wash the caliper components with fresh brake

fluid before reassembly. Never use cleaning sol-

vent or gasoline to wash them. Apply brake fluid

to the caliper bore and all internal parts before

inserting into the bore.

If measurement exceeds the service limit, replace the

brake disc. (Refer to page 6-2)

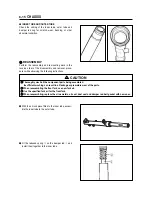

BRAKE DISC INSPECTION

Check the brake disc for damage or cracks. Measure the

thickness using the micrometer.

Replace the brake disc if the thickness is less than the

service limit or if damage is found.

Measure the runout using the dial gauge.

Replace the brake disc if the runout exceeds the service

limit.

Service limit

3.0 mm (0.12 in)

Brake disc thickness

Service limit

0.3 mm (0.012 in)

Brake disc runout

Micrometer (0 25 mm) : 09900-20201

Dial gauge : 09900-20606

Magnetic stand : 09900-20701

CHASSIS

6-8