1

Tuff Torq K61 Hydrostatic Transaxle

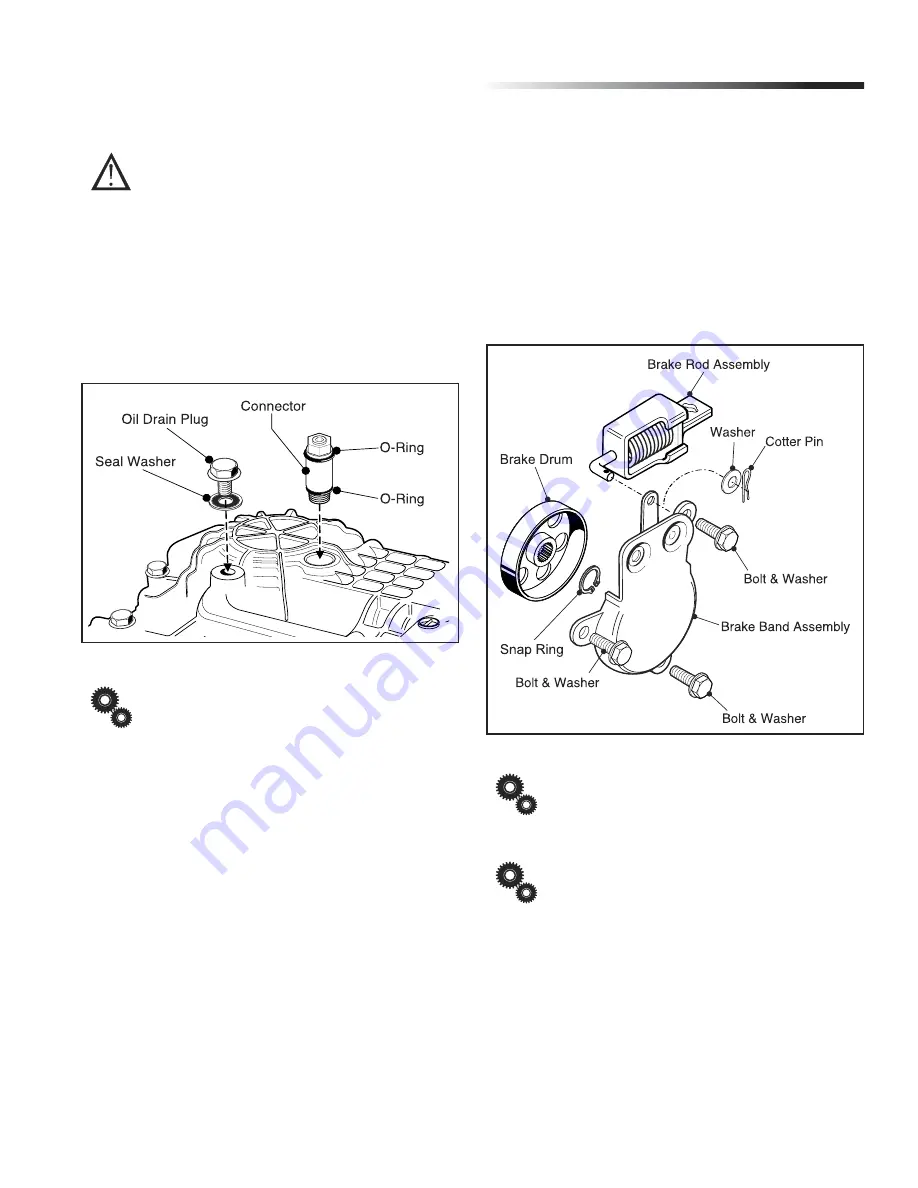

Drain Oil

Before beginning tear-down clean work area

thoroughly and cover workbench with clean paper.

This is extremely important as just one grain of sand

can cause damage to the Hydrostatic Rotating Group

in the Transaxle.

1. Remove the Oil Drain Plug (12 mm wrench) from the

Lower Case of Transaxle and drain oil.

(Fig. 1)

2

.

Remove the Connector (14 mm wrench) from the Center

Case, through the Lower Case and drain the oil from the

Hydrostatic Rotating Groups.

(Fig. 1

)

Fig. 1, Oil Drain Plug and Pressure Fill Plug removal

Always install a new Seal Washer on the Drain

Plug and new O-rings on Pressure Fill Plug when reas-

sembling.

Brake Assembly Removal

1. Remove the Cotter Pin and Washer from the Brake Rod

Assembly.

(Fig. 2)

2. Remove the Brake Rod Assembly from Brake Arm B (see

Fig. 3) by pivoting 90 degrees and sliding downward.

(Fig. 2)

3. Loosen and remove the (3) 8 mm bolts/washers (12mm

wrench) and detach the Brake Assembly.

(Fig. 2)

4. Remove Snap Ring (Snap Ring Pliers) and the Brake

Drum from Brake Shaft.

(Fig. 2)

Fig. 2, Brake Assembly Removal

Inspect all brake components for wear or dam-

age. Replace as necessary.

Brake drum and brake band are to be free from

oil and dust.

Disassembly of Transaxle