22 –

English

SAFETY INSTRUCTIONS

The machine’s position on the loading platform

•

Position the machine against the front edge of the

platform in order to reduce the risk of it sliding forward if

the vehicle brakes.

•

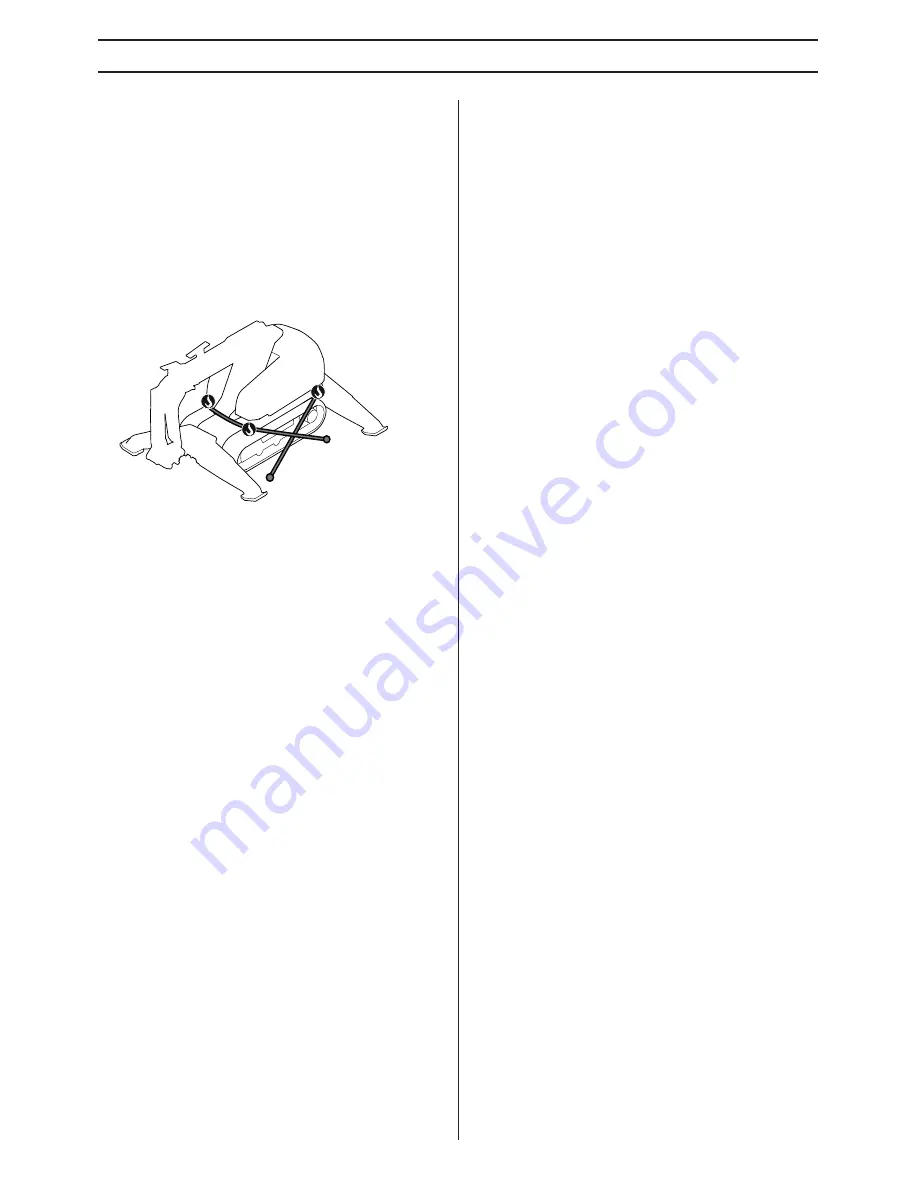

Manoeuvre the arm system so that it is resting against the

platform, positioned as low as possible. Extend the

outriggers without lifting the machine.

Securing the load

•

Secure the machine with approved tightening straps.

Ensure that no part of the machine are squashed or

damaged by the tightening straps. It is a good idea to

cover the machine.

•

Tools and other equipment must be secured with separate

tightening straps.

•

Regularly check that the load is secure during

transportation.

Storage

•

Remove the tool from the machine.

•

Retract the arm system to attain a centre of gravity that is

as low as possible and to save space.

•

Store the equipment in a lockable area so that it is out of

reach of children and unauthorized persons.

•

Store the machine and its equipment in a dry and frost

proof place.

•

The main switch on the machine can be locked with a

padlock to prevent unauthorised persons from starting the

machine.

Towing

The machine is not designed to be towed. When the machine

is depressurized, the drive motor’s parking brakes are

activated and the caterpillar tracks cannot rotate. Only tow the

machine if its position constitutes a risk and there is no other

solution. Tow it for the shortest possible distance.

•

If possible, retract the outriggers before towing the

machine in order to reduce the risk of them getting stuck

and being damaged.

•

To minimize the load on the towing device and mechanical

components, reduce the friction by preparing the route

that the machine is going to be towed.

•

If possible tow in the direction of the tracks.

•

Use a towing device intended for the particular load.

•

Parts can loosen during towing. Keep your distance!

Maintenance and service

Most accidents involving machines occur during trouble

shooting, service and maintenance as staff have to locate

themselves within the machine’s risk area. Prevent accidents

by being alert and by planning and preparing the work. You

can also refer to 'Preparations for maintenance and service”

in the 'Maintenance and service” section.

•

Never carry out repairs without having the necessary

expertise.

•

The user must only carry out the maintenance and service

work described in this Operator's Manual. More extensive

work must be carried out by an authorized service

workshop.

•

Use personal protective equipment as well as equipment

to mechanically secure machine components during

maintenance and service.

•

Only trained service personnel are permitted to intervene

in the electrical or hydraulic systems.

•

Set out clear signs to inform persons in the vicinity that

maintenance work is in progress.

•

If service operations or trouble shooting does not require

the machine to be switched on, the power cable must be

removed and positioned so that it cannot be connected by

mistake.

•

Ensure there is no current to the machine by removing the

power cable before opening or removing the electric

cabinet or any other component that contains electrical

current.

•

Pipe and hose couplings can remain pressurized despite

the motor being switched off and the power cable

disconnected. It must always be assumed that hydraulic

hoses are pressurized and they must be opened with

great care. Relieve the pressure on the arm system by

resting it on the ground and turn off the electric motor

before undoing the hoses.

•

Never try to stop hydraulic oil leaking from a broken hose

by hand. Finely dispersed hydraulic oil at high pressure

can permeate under the skin and cause very severe

injuries.

•

When dismantling machine parts, heavy components can

start moving or fall down. Secure moving parts

mechanically before loosening screw joints or hydraulic

hoses.

•

Use an approved lifting device to secure and lift heavy

machine parts.

•

Several components heat up during work with the

machine. Do not commence any servicing or

maintenance tasks until the machine has cooled.

•

Keep work area clean and well lit.

Cluttered or dark

areas invite accidents.

•

The machine’s movements can be defective if a terminal,

cable or hose is incorrectly assembled. Exercise caution

during test runs and be prepared to turn off the machine

immediately in the event of a fault.

Summary of Contents for DXR300

Page 55: ...English 55 TECHNICAL DATA 4868 192 2368 93 5231 206 1818 72 ...

Page 58: ......

Page 59: ......

Page 60: ... z X16 6y 2013 09 25 z X16 6y 1156172 26 GB Original instructions ...