Product Information

Environmental Specifications

Chapter 1

1-6

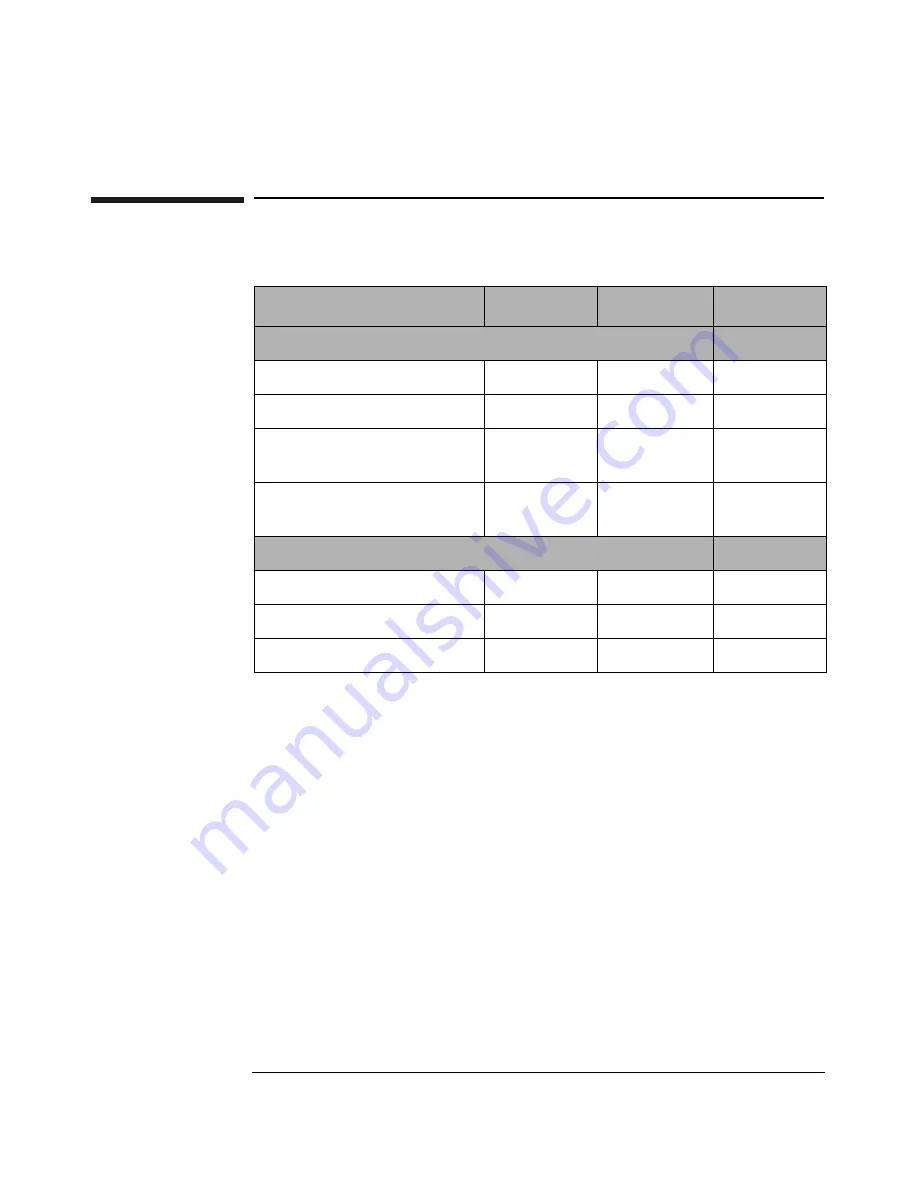

Environmental Specifications

Table 1-2

Environmental Specifications

Characteristics

Robotics

Drive

Media

Temperature (o C)

Operating

10 to 40

5 to 45

10 to 60

Non-operating w/o disk

- 40 to 70

- 40 to 60

10 to 60

Max. Temperature

gradient (o C /hr)

10 10 10

Transportation - <14

consecutive days

-40 to 60

Humidity, non-condensing (%)

Relative operating

10 to 90

5 to 90

10 to 80

Non-operating w/o disk

5 to 95

5 to 95

10 to 90

Maximum wet bulb (o C)

29

29

29

Summary of Contents for Surestore 160ex - Optical Jukebox

Page 10: ...TOC x Contents ...

Page 14: ...Tables TOC xiv ...

Page 15: ...Chapter 1 1 1 Product Information 1 Product Information ...

Page 26: ...Product Information Environmental Specifications Chapter 1 1 12 ...

Page 27: ...Chapter 2 2 1 Installation 2 Installation ...

Page 30: ...Installation Identifying Controls and Features Chapter 2 2 4 Figure 2 2 Left Side ...

Page 47: ...Chapter 3 3 1 Operation and Configuration 3 Operation and Configuration ...

Page 75: ...Chapter 4 4 1 Troubleshooting and Diagnostics 4 Troubleshooting and Diagnostics ...

Page 122: ...Troubleshooting and Diagnostics Running an Internal Test Chapter 4 4 48 ...

Page 123: ...Chapter 5 5 1 Removal and Replacement 5 Removal and Replacement ...

Page 129: ...Removal and Replacement Service Access Chapter 5 5 7 Removal and Replacement Front Panel ...

Page 188: ...Removal and Replacement Replaceable Parts Chapter 5 5 66 Figure 5 43 Exploded View 1 of 3 ...

Page 190: ...Removal and Replacement Replaceable Parts Chapter 5 5 68 Figure 5 45 Exploded View 3 of 3 ...

Page 192: ...Removal and Replacement Replaceable Parts Chapter 5 5 70 Figure 5 47 Rope and Pulley System ...

Page 193: ...Chapter 6 6 1 Theory of Operation 6 Theory of Operation ...

Page 218: ...Theory of Operation Optical Drive Mechanism Chapter 6 6 26 ...

Page 219: ...Appendix A A 1 Safety and Regulatory A Safety and Regulatory Information ...