Midas

®

Gas Detector

8-2

8 Maintenance

Midas

®

is a fully serviceable product designed with

modular components that can be readily replaced

by trained service personnel so as to minimize the

time that the gas detector is not available.

External in-line air filters should be replaced every

three months or more frequently if the system is

sampling in environments that have high levels of

particulate matter or very acidic / wet atmospheres.

Similarly, the internal particulate filter should be

replaced once a year or more frequently if the

sample lines are prone to heavy contamination.

Every sensor cartridge is shipped with a 12 month

warranty and an extended 2 year warranty sensor

cartridge is also available for purchase. All sensor

cartridges are factory calibrated to traceable

national standards before shipment to the end user.

Note that testing or calibrating with the wrong

(incorrect, out of date, non-traceable) calibration

gases, calibration equipment, methods or operating

conditions can actually damage the sensor

cartridge’s lifetime and alter the calibration

adversely. Only qualified calibration technicians

should attempt to calibrate the Midas

®

gas detector.

Note

For details regarding sensor cartridge

calibration and bump testing method refer

to

Section 17

.

The internal pump module is designed to operate

for a minimum of 24 months and it is recommended

that this pump module (part number MIDAS-A-007)

be replaced every 2 years.

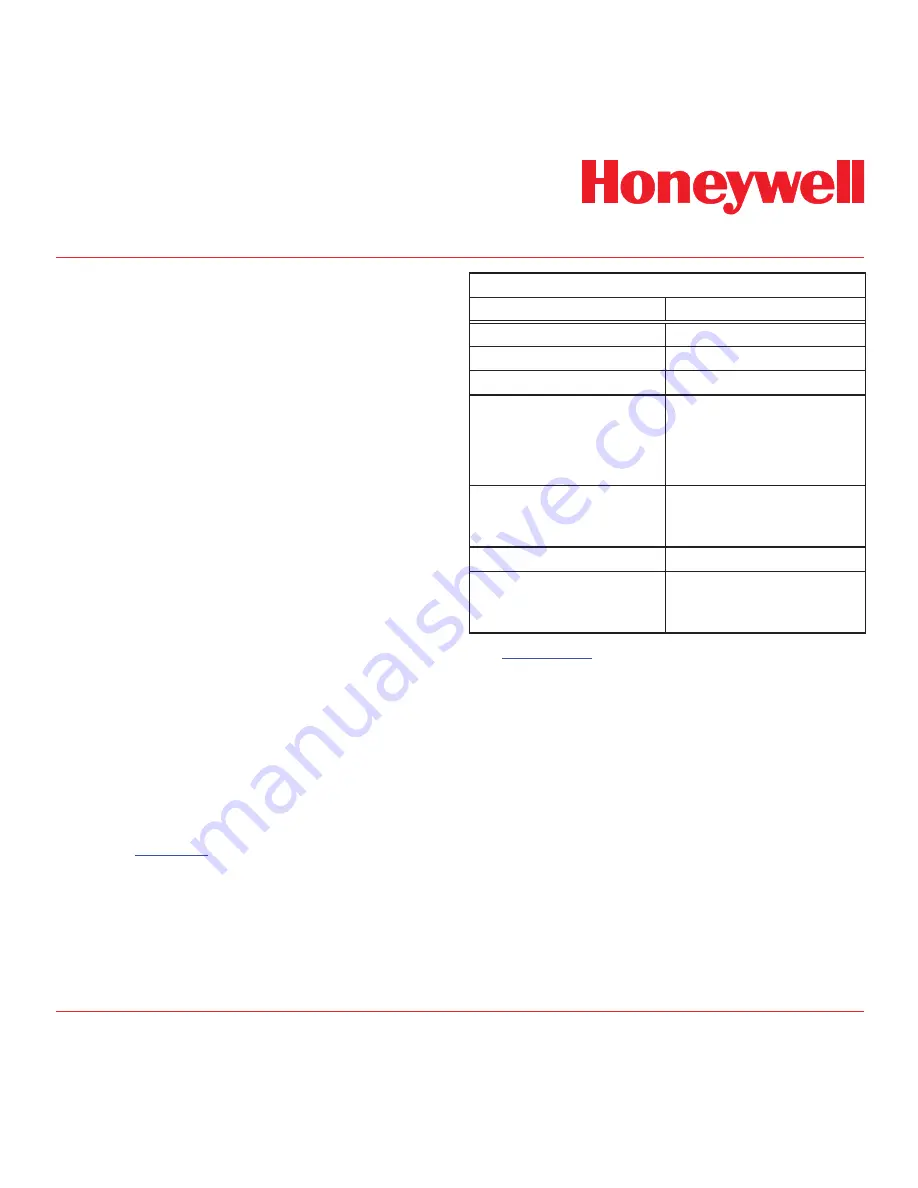

Recommended Maintenance Schedule

Component

Frequency

Pump

2 years/as needed

Pyrolyzer (all models)

1 year

Internal Filter

2 years/as needed

External Sample Line Filter 780248 3-6 months

1991-0147 3-6 months

1830-0055 3-6 months

1830-0027 1 month

Leak Check

Leak Check every 6 months

or after pump, pyrolyzer or

internal filter replacement.

Bump Test

6 months

Flow Calibration

Flow Calibrate after pump,

pyrolyzer or internal filter

replacement.

See

Appendix B

for the correct filter requirement for

your application.

Note

The CO2 cartridge MIDAS-S/E-CO2 bias

battery will last only about 9 months. After

replacement, allow at least a day for the

cartridge to reach equilibrium.

Summary of Contents for Midas

Page 7: ...Midas Gas Detector 1 1 1 Description ...

Page 9: ...Midas Gas Detector 2 1 2 Overview ...

Page 14: ...Midas Gas Detector 3 1 3 Default Configuration ...

Page 17: ...Midas Gas Detector 4 1 4 Installation ...

Page 41: ...Midas Gas Detector 5 1 5 Startup ...

Page 43: ...Midas Gas Detector 6 1 6 Operation ...

Page 53: ...Midas Gas Detector 7 1 7 Navigating Modes and Submenus ...

Page 74: ...Midas Gas Detector 8 1 8 Maintenance ...

Page 82: ...Midas Gas Detector 9 1 9 Pyrolyzer Module Options ...

Page 89: ...Midas Gas Detector 10 1 10 Optional LonWorks Interface Installation ...

Page 99: ...Midas Gas Detector 11 1 11 Troubleshooting and Fault Diagnosis ...

Page 102: ...Midas Gas Detector 12 1 12 REFLEX ...

Page 104: ...Midas Gas Detector 13 1 13 Internal Web Server ...

Page 106: ...Midas Gas Detector 13 3 Diagram 13 1 IPAddress setting in Windows XP ...

Page 129: ...Midas Gas Detector 14 1 14 Typical Installation Topologies ...

Page 132: ...Midas Gas Detector 15 1 15 Ordering Information ...

Page 136: ...Midas Gas Detector 16 1 16 Specifications ...

Page 139: ...Midas Gas Detector 17 1 17 Calibration and Bump Testing ...

Page 143: ...Midas Gas Detector A 1 A Modbus TCP Interface ...

Page 150: ...Midas Gas Detector B 1 B Gas Tables ...

Page 158: ...Midas Gas Detector C 1 C Warranty ...