VISTA-120 Installation and Setup Guide

3-16

RS-485 Bus Wire Run Limitations

The RS-485 bus from the first Panel Linking Module to

the last Panel Linking Module cannot exceed 1220m,

using 1.3mm twisted-pair cable.

The recommended form of wiring is to daisy chain the

connection from one unit to another. If several buildings

are to be connected, the RS-485 bus should form a

continuous path from one building to the next.

Avoid wiring units in a star configuration, where

multiple branches are formed. Star configurations

create loading and capacitance problems that are

complex, and become difficult to troubleshoot.

Mounting and Wiring the Panel Link Module

The PLM will not operate until the device is

enabled in the control’s

Device Programming in

#93 Menu Mode.

Do not mount the PLM on the cabinet door or

attempt to attach it to the PC board.

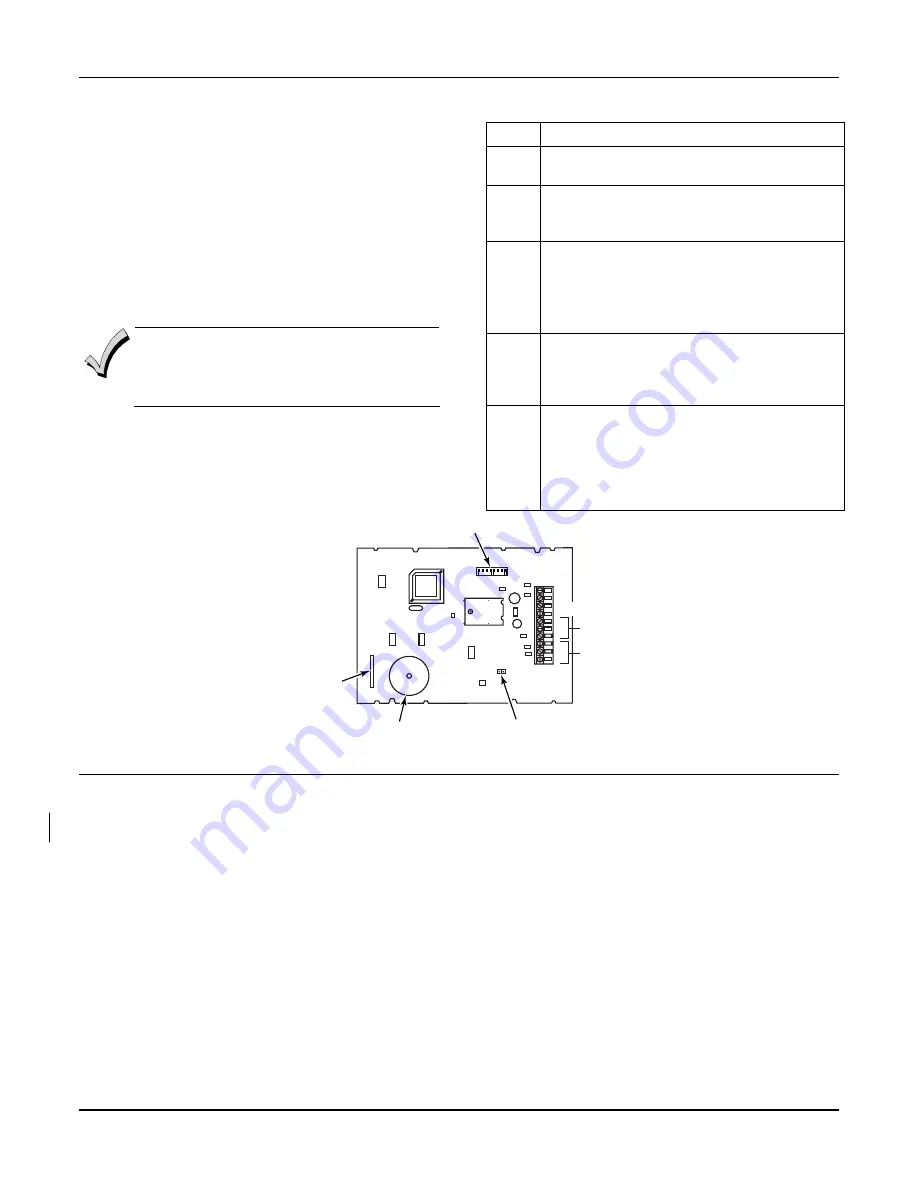

To mount and wire the Panel Link Module, refer to

Figure 3-27

and

perform the following steps:

Step Action

1

Remove all power from the control panel

before making any wiring connections.

2

Mount the module in the control cabinet if

space is available or, adjacent to the cabinet,

using 2-faced adhesive tape.

3

Set the PLM’s DIP switches for a device

address between 01 and 30. See the module’s

instructions for the DIP switch table.

Do not use an address being used by another

device (keypads, RF receivers, etc.).

4

Connect the 12V (+) and (–) and data-out and

data-in connections from the PLM to the

control’s keypads terminals (6, 7, 8, and 9),

respectively.

5

Connect the 3-wire RS-485 cable between

each PLM. Recommended wiring is to bring

the wires “in” from one module (or control

panel) to terminals 5 (+), 6 (-), and 7 (G) and

“out” to the next module from terminals TB1-

8 (+), 9 (-), and 10 (G).

+

_

G

+

_

G

+

_

1 2 3 4 5 6 7 8

PLG-002-V0

RS-485

RS-485

EOL

JUMPER

PINS

PIEZO

SOUNDER

TAMPER

REED

SWITCH

DIP

SWITCH

ECP IN

ECP OUT

Figure 3-27: VA8200 Panel Link Module Wiring

Event Log Printer Connections

This system has the ability to record up to 512 events of

various types in a history log (512 event capacity).

Each event is recorded in one of five categories with the

time and date of its occurrence (if real-time clock is set).

These categories are Alarm, Supervisory/Check,

Bypass, Open/Close, and System Conditions.

The log may be viewed (Display Mode) on an alpha

keypad, or can be printed (Print Mode) on a serial

printer (connected to the system via a 4100SM serial

interface module.

Printer Configurations

Printer must be configured as follows:

•

8 data bits, no parity, 1 stop bit

•

300 or 1200 baud (1200 preferred)

•

Hardware handshaking using DTR signal

•

The 4100SM module package includes a 3m RS232

cable. You can use a longer cable or an extension

cable if the Control and serial printer are separated

by more than 3m. The total cable length should be

less than 15m.

•

Most printers either ignore the CTS, DSR and CD

signals, or require them to be high (i.e. 3-15VDC as

measured on RS232 DB25 connector pins 5, 6 & 8

respectively with respect to ground pin 7). The

4100SM module sets these pins high. If the printer

does not operate with these pins high, then clip the

blue (CTS), white (DSR) or red (CD) jumpers on the

4100SM module to set the corresponding signal

floating. Important pins on the RS232C cable are

pin 3 (data out), pin 7 (ground) and pin 20 (DTR -

ready).

Summary of Contents for ADEMCO VISTA-120

Page 2: ...ii ...

Page 18: ...VISTA 120 Installation and Setup Guide 2 8 ...

Page 70: ...VISTA 120 Installation and Setup Guide 5 16 ...

Page 88: ...VISTA 120 Installation and Setup Guide 7 4 ...

Page 90: ...VISTA 120 Installation and Setup Guide 8 2 ...

Page 100: ...VISTA 120 Installation and Setup Guide A 2 ...

Page 104: ......

Page 106: ......

Page 113: ......