44 | EngliSH

3.3.5. Pump housing

The pump housing, depending on the model, is supplied

with different connections. This means that the machine

can be connected with the respective pipe system. The

pump housing is also available rubber-coated inside.

Some pump housings are supplied with a cleaning hole lid

to eliminate blockages.

The pump can equipped with a stationary wear ring which

can be found in the intake port. This wear ring determines

the gap between the impeller and the intake port. If this

gap is too big, the performance of the pump decreases

and it can lead to blockages. The rings can be changed to

minimize wear and expenses for spare parts.

3.3.6. Impeller

The impeller is fastened directly to the motor shaft and

driven by it. The impeller is also available in different ma-

terials (GG, GGG, VA, BZ) or coated with ceramic liquid.

A range of different impeller designs are available:

M:

Enclosed single channel impeller, for liquids containing

impurities and sludge with solid particles or long fibres.

K:

Enclosed multi channel impeller, for liquids containing

impurities and sludge with solid particles.

V:

Vortex impeller, for liquids containing a high level of impurities

or fibrous matter and containing gas.

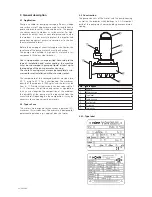

Direction of rotation control

All pumps run in the correct direction of rotation when

connected to a clockwise rotating field (U, V, W -> L1, L2,

L3). HOMA switchgears check the grid for a clockwise

rotating field. If there is no clockwise rotating field, the

red LED is lit. Two phases are to be exchanged at the

input to the switchgear. With smaller pumps, the check

can be made by observing the starting jerk. For this pur-

pose, place the pump perpendicular to the floor, slight-

ly on edge, and switch on briefly. Seen from above, the

pump jerks slightly anticlockwise if the direction of rota-

tion is correct. The direction of rotation of the pump is

correct if the pump moves anticlockwise because, seen

from above, the motor starts in the clockwise direction.

ST

AR

T

REACTION

ROTOR

REACTION

ATTENTION

The

direction of rotation

is correct if the

impeller/propeller rotates

in a

clockwise

manner

when viewing down from

top of the placed unit

ATTENTION

The

start reaction

is

anti clockwise

With bigger pumps the check may be done by watching

the rotation of the impeller through the discharge or suc-

tion inlet. Switch the pump on and off and check the direc-

tion of rotation when the impeller rotates slowly.

Beware of rotating impeller!

The moving impeller can crush and sever limbs.

Never reach into the pump unit or the moving parts

during operation. Switch off the machine and let the

moving parts come to a rest before maintenance or

repair work!

Additional the direction of rotation can control by a “motor

& phase rotation indicator”, which must put on the motor

housing of the operating pump.

Seal condition sensors at pumps with oil chamber

•

Models without cooling jacket or model „U“ with

cooling jacket and open circuit cooling:

In case of water entering the oil chamber through the shaft

seals, the resistance will change. The electrical resistance

of the oil in the oil chamber is measured by 2 sensors. The

sensors must be connected by 2 wires (marked S1 and

S2) of the pump connecting cable in the control panel with

a tripping unit with galvanically separated safety circuit.

The tripping unit should have an adjustable sensitivity of 0

to 100 k

Ω

, standard setting is approx. 50 k

Ω

.

Cable connection seal condition sensors

The cable connecting chamber is controlled by two sen-

sors for entering of water. The sensors must be connect-

ed by 2 wires (marked S3 and S4) of the pump connecting

cable in the control panel with a tripping unit with galvani-

cally separated safety circuit.

Motor cooling

Motors for submerged operation are cooled by the sur-

rounding liquid.

3.3.4. Sealing

The sealing between pump and motor is carried out by

two separate mechanical shaft seals (silicon-carbide) in

tandem-arrangement. It is made of bearing cover and

pressure cover. It is filled with medical white oil. Separate

large oil chamber, lubricating and cooling the mechanical

seals, forming an extra safety and inspection element.

Summary of Contents for AM***-C

Page 1: ...Original Betriebsanleitung EN Original Instruction Manual AM X AV X C D C D 60 Hz ...

Page 35: ...DEUTSCH 35 Notizen Notes ...

Page 66: ...66 Notizen Notes ...

Page 67: ...67 Notizen Notes ...

Page 70: ...70 Notizen Notes ...

Page 71: ...71 ...