5-10

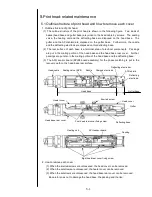

Makeup ink IN joint

Sealing valve presser foot

Sealing valve

Nozzle IN joint presser foot

Heating unit

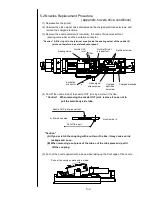

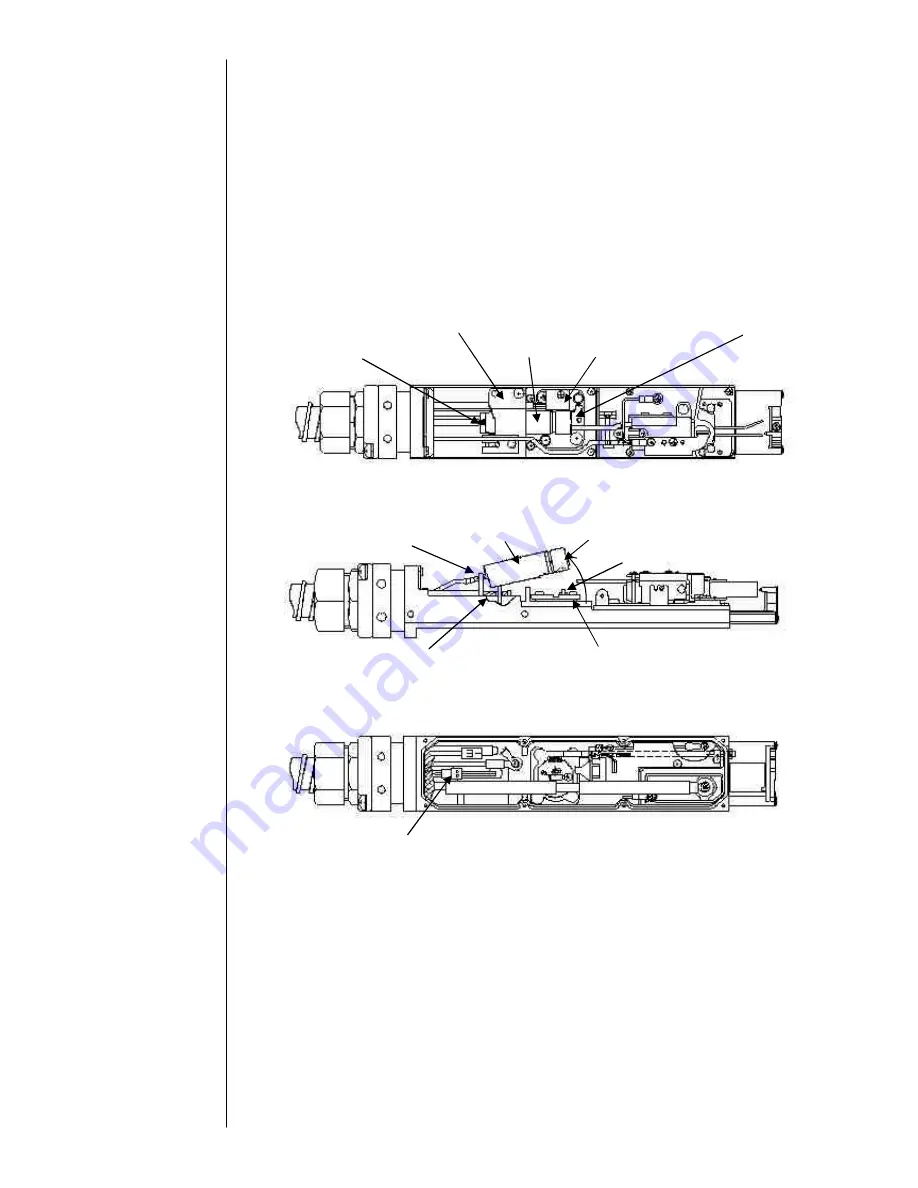

5.5 Sealing valve (MV9) Replacement Procedure

(1) Depressurize the printer.

(2) Remove the head cover and the heater cover.

(3) Remove the head base rear cover and disassemble the connector of the sealing

valve.

(4) Unloosen the nozzle IN joint presser foot and the sealing valve presser foot.

(A) A filter is put in the terminal area (inside the sealing valve) of the nozzle

IN joint.

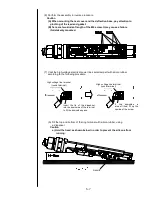

(5) Take up the sealing valve, remove the makeup ink IN joint and remove the sealing

valve.

(A) Lift the fore of the sealing valve as in the drawing.

(B) When the O-ring (P2.2) is remained at the heating unit, remove it.

Sealing valve connector

Makeup ink IN joint

Sealing valve

O-ring P2.2

Heating unit

Filter

Sealing valve packing

Summary of Contents for IJ PH

Page 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Page 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Page 13: ...1 2 2 Main body internal PH D 1 8 ...

Page 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Page 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Page 202: ...7 2 7 2 Electrical Connection Diagram ...

Page 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...