5-11

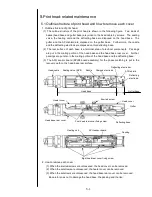

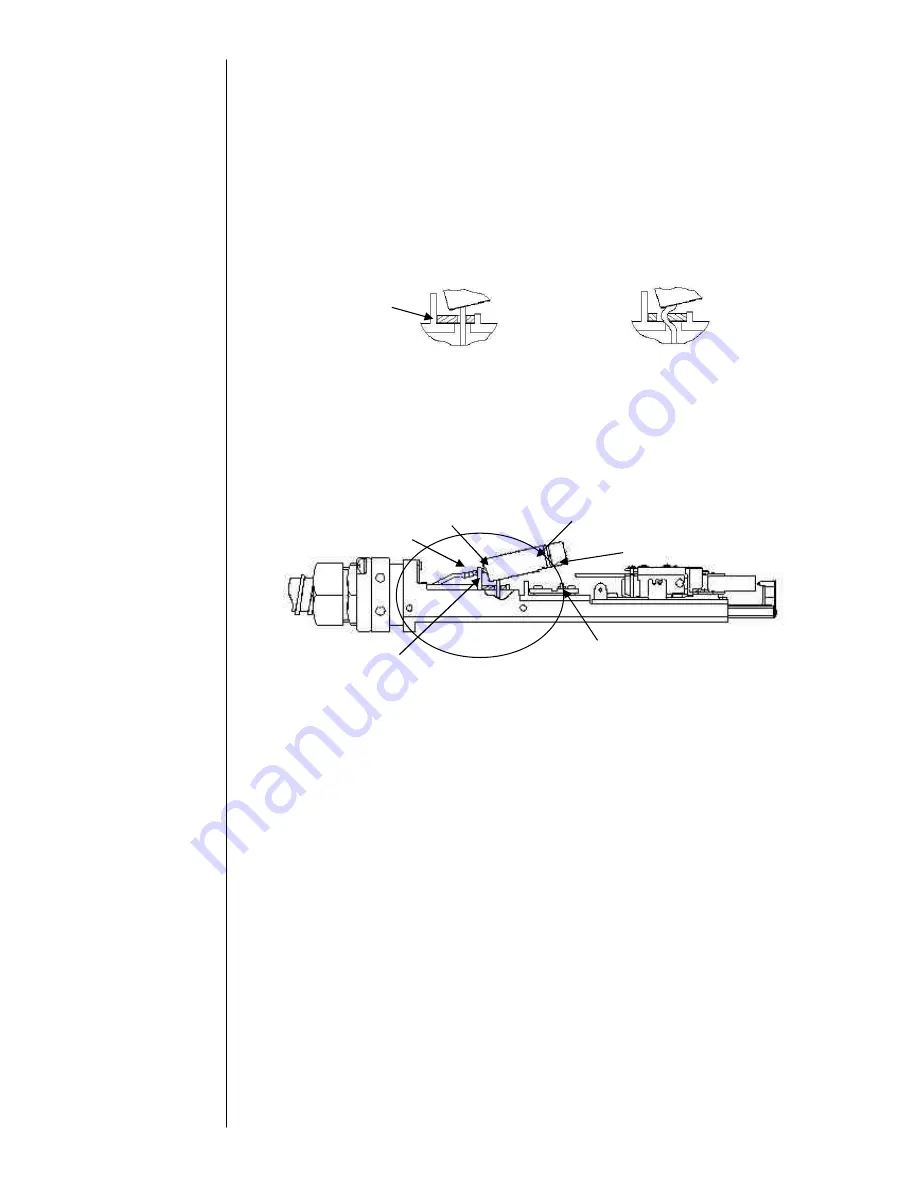

(6) Prepare a new sealing valve and put O-rings into the respective holes of the joint part.

(A) Put the O-ring P2.2 (hole diameter: about

φ

2.1) into the hole on the heating unit

side and put the O-ring P1.7 (hole diameter: about

φ

1.6) into the hole on the

makeup ink IN side.

(B) Be sure to put the O-rings so as not to jump out of the hole of the joint part.

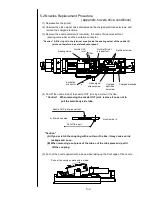

(7) Put the sealing valve packing into the sealing valve lead wire and set it to a

predetermined position of the head base.

(A) Be careful to the direction of the sealing valve packing.

(8) Connect the makeup ink IN joint to the sealing valve and fix it to the boss on the

heating unit.

(A) Put the makeup ink IN joint in the groove of the head base rib.

(B) Perform the assembly after putting the makeup ink on the O-ring, and confirm

that the O-ring does not jump out of the hole.

(C) Be careful not to apply the makeup ink to the A portion below.

(9) Attach the sealing valve presser foot and fix the sealing valve.

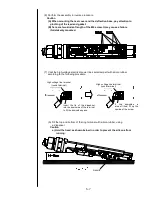

(10) Put the filter and the nozzle IN joint in this order and fix it by the nozzle IN joint

presser foot.

(A) Refer to the nozzle replacement work sequence.

(11) Assemble the sealing valve connector and attach the head base rear cover.

(A) Surely put the packing into the groove and attach the cover.

(B) Be careful so as not to pinch the lead wires.

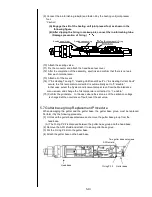

(12) Spurt ink after the assembly and confirm that there is no leak from each terminal

area.

(13) Attach each cover.

*It is necessary for using JP-K31A ink, JP-B27 ink and JP-W73 to change the sealing valve

filter periodically.

(Target for the change :2400 hours)

OK

NG

Sealing valve packing

Makeup ink IN joint

Sealing valve

O-ring P2.2

Heating unit boss

O-ring P1.7

Head base rib

A parts

Summary of Contents for IJ PH

Page 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Page 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Page 13: ...1 2 2 Main body internal PH D 1 8 ...

Page 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Page 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Page 202: ...7 2 7 2 Electrical Connection Diagram ...

Page 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...