5-3

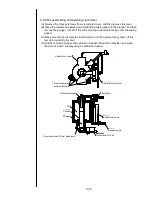

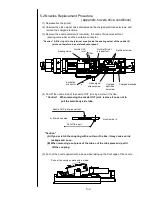

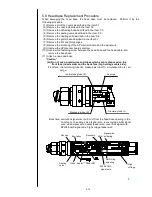

(6) Attach a new nozzle and fix the nozzle setscrew, (2 locations), the nozzle IN joint

presser foot (sealing valve side), the nozzle OUT joint and the excitation connector.

“Caution”

(A) Confirm that a filter is present in the terminal area (inside the sealing

valve) of the nozzle IN joint.

(B) Wet the insert portion inside the sealing valve with the intensifier

to make it slippery and then, connect the nozzle IN joint.

“Caution”

If connection is imperfect, ink will below off.

The nozzle attachment position differs for different nozzle diameters as shown below:

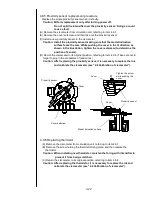

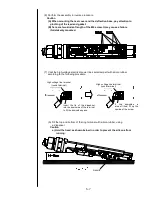

(7) Cut the recovery side tube of the new nozzle into a suitable length and connect the

nozzle OUT joint.

“Caution”

(A) Get rid of the tube remaining on the joint in the (4).

(B) When the tube is hardly put in the joint because it slips, grasp the front

edge of the tube by a JK wiper or the like and put it in the joint.

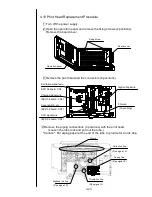

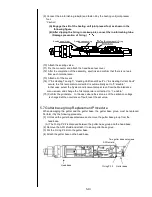

(8) Put the charged electrode in the new nozzle and fix the video signal wire on the

charged electrode.

(9) Execute Ink stream alignment on the Circulation control screen.

“Caution”

(A) If you repeat Ink stream alignment, it will be diluted. Complete it by the third

time.

(10) Perform Excitation adjustment and Auto phase gain adjustment on the screen of

Adjustment/operation checkout.

(2 locations)

Recovery side tube

Nozzle setscrew

Take in the stepped part

Nozzle IN joint

presser foot

Filter

Nozzle out joint

Sealing

valve

O-ring P3.9

PH 65

µ

m nozzle

attachment position

Summary of Contents for IJ PH

Page 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Page 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Page 13: ...1 2 2 Main body internal PH D 1 8 ...

Page 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Page 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Page 202: ...7 2 7 2 Electrical Connection Diagram ...

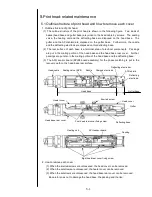

Page 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...