6-63

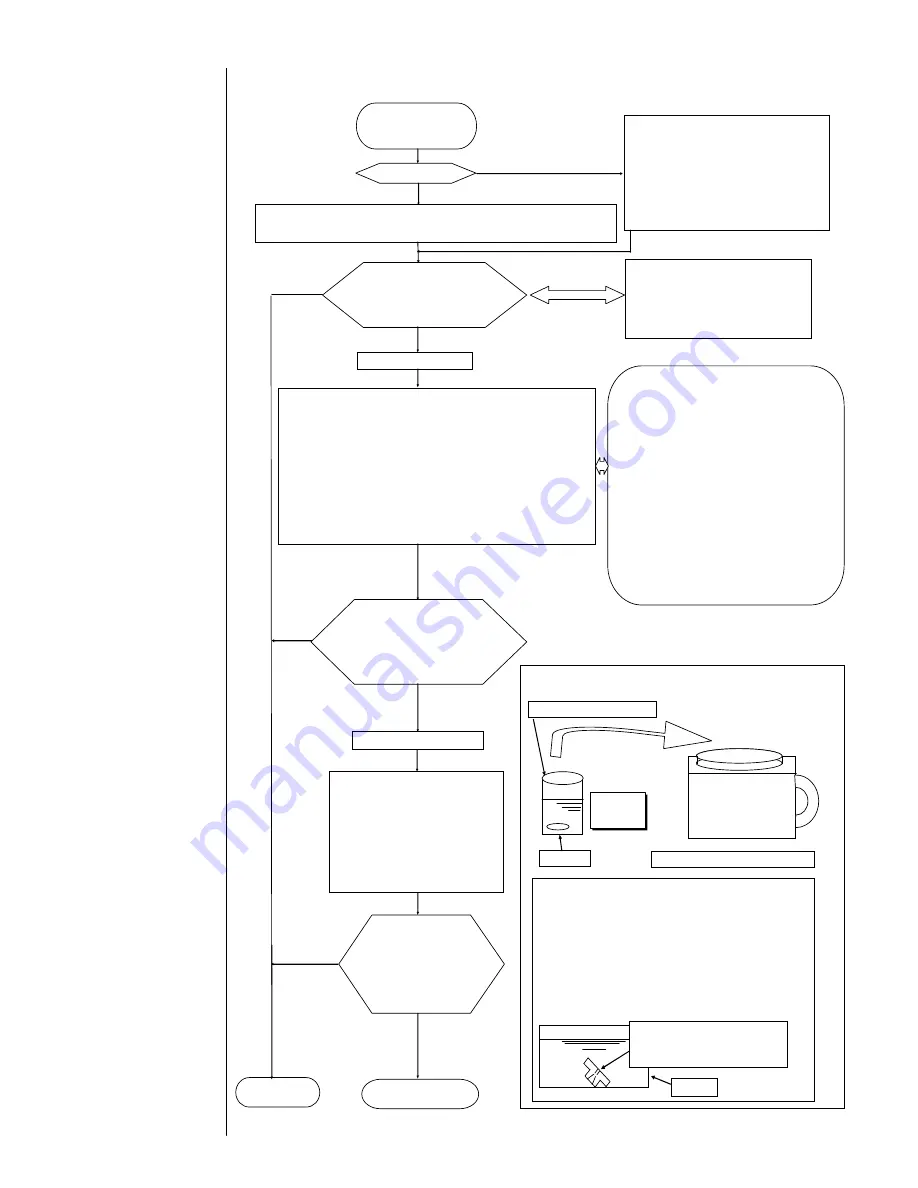

6.6.11 Nozzle clog, Ink beam bending trouble

Nozzle clog , Ink beam

bending trouble happened.

1)It executes to clean an out side of orifice by cleaning paper with Make up ink.

2)If it cannot repair, then it practices nozzle backwash.

It practices Nozzle forward

wash. (*1) And it confirms ink

beam position to the Gutter.

It practices Ultrasonic cleaning.

<Cleaning method>

1)It detaches orifice plate

2)It cleans orifice plate by the make up ink

for approximate15 minute.

3)If possible, it checks whether the foreign

substance still remains or not by Micro

scope.

It re-assembles the

orifice plate.

Then it confirms ink beam

position to the Gutter by nozzle

forward wash mode.

It detaches orifice plate again

It practices Ultrasonic cleaning by water

<Cleaning method>

1)It cleans orifice plate by water to be added detergent with the surface-

active agent for dish. Also Percentage of the detergent is approximate

0.5% to water.

2)Cleaning time is approximate 10 minutes.(* 2)

3)Then it rinses the orifice plate by drinking water.(About 1minute)

4)Then it rinses the orifice plate by the Make up ink.(About 1 minute)

5)If possible, it checks whether the foreign substance still remains or

not by Micro scope.

Continuing run

*1 : How to do nozzle forward wash

<PH type>

[Ink stream adjustment] of Circulation

control menu screen.

The Ultrasonic cleaning method for Nozzle

Water with

detergent

Stainless steel or Glass beaker

Orifice plate

Ultrasonic cleaner put water or hot water

<Notice>

1)Do use enough clean beaker & clean water, make-up ink

& NC01. Or nozzle clog sometimes will occur.

2)The beaker which put orifice plate should be chosen thin

wall one. Also flexible cup made from flexible plastic etc.

is not good. If it is used heavy walled vessel or flexible

cup, the cleaning power drop down because of periodic

damping of the ultrasonic power.

3)Put the orifice plate as shown in the figure below.

It can not repair

Ink beam

position is OK

Ink beam position

is OK

Ink beam position

is not good.

Ink beam position

is OK

It practices Ultrasonic cleaning again.

<Cleaning method>

1)It cleans orifice plate by the Nozzle

cleaning liquid for approximate10

minute.

2)If possible, it checks whether the

foreign substance still remains or

not.

Ink beam position is

not good.

Can ink eject ?

It detaches orifice plate.

It re-assembles the

orifice plate.

Then it confirms ink

beam position to the

Gutter by nozzle forward

wash mode.

* 2 The effect of each solution which is used for

Ultrasonic cleaning.

- Make-up ink

It can speed to dissolve constituent of the ink.

- Water with detergent

(Including the surface-active agent)

It can peel & remove a substance which can not

dissolve. If it is used a hot water, the cleaning

power will come strong.

- Nozzle cleaning liquid

It can dissolve insoluble substance that peeling

is difficult.

Inform to Hitachi

YES

NO

This is the orifice plate.

Incline as shown in this figure and

put outside of orifice to be upper.

Beaker

Summary of Contents for IJ PH

Page 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Page 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Page 13: ...1 2 2 Main body internal PH D 1 8 ...

Page 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Page 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Page 202: ...7 2 7 2 Electrical Connection Diagram ...

Page 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...