4-22

4.9.5 Proximity sensor replacement procedure

Replace the single proximity sensor when it is faulty.

Caution: Perform replacement only after turning power off.

Do not spill the intensifier over the proximity sensor: Doing so could

cause a fault.

(A) Remove the viscometer from circulation unit, referring to item 4.9.1.

(B) Remove the cover setscrew, and then take out the proximity sensor.

(C)Install a new proximity sensor in the viscometer.

Caution: Install the proximity sensor making sure that the model indication

surface faces the rear. While pushing the cover in the Q direction as

shown in the illustration, tighten the cover setscrew (to determine the

position of sensor).

(D) Return the viscometer to its original position, referring to item 4.9.4. (Take care not to

forget to plug in the connectors of lead wires.)

Caution: After replacing the proximity sensor, it is necessary to replace the ink

and calibrate the viscometer (see “2.6 Calibration of viscometer”).

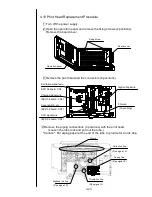

4.9.6 Replacing thermistor

(A) Remove the viscometer from circulation unit, referring to item 4.9.1.

(B) Remove the screw holding the thermistor fixing plate, and then replace the

thermistor.

Caution: When installing new thermistor, moisten the O-ring with intensifier to

prevent it from being scratched.

(C) Return the viscometer to its original position, referring to item 4.9.4.

Caution: After replacing the thermistor, it is necessary to replace the ink and

calibrate the viscometer (see “2.6 Calibration of viscometer”).

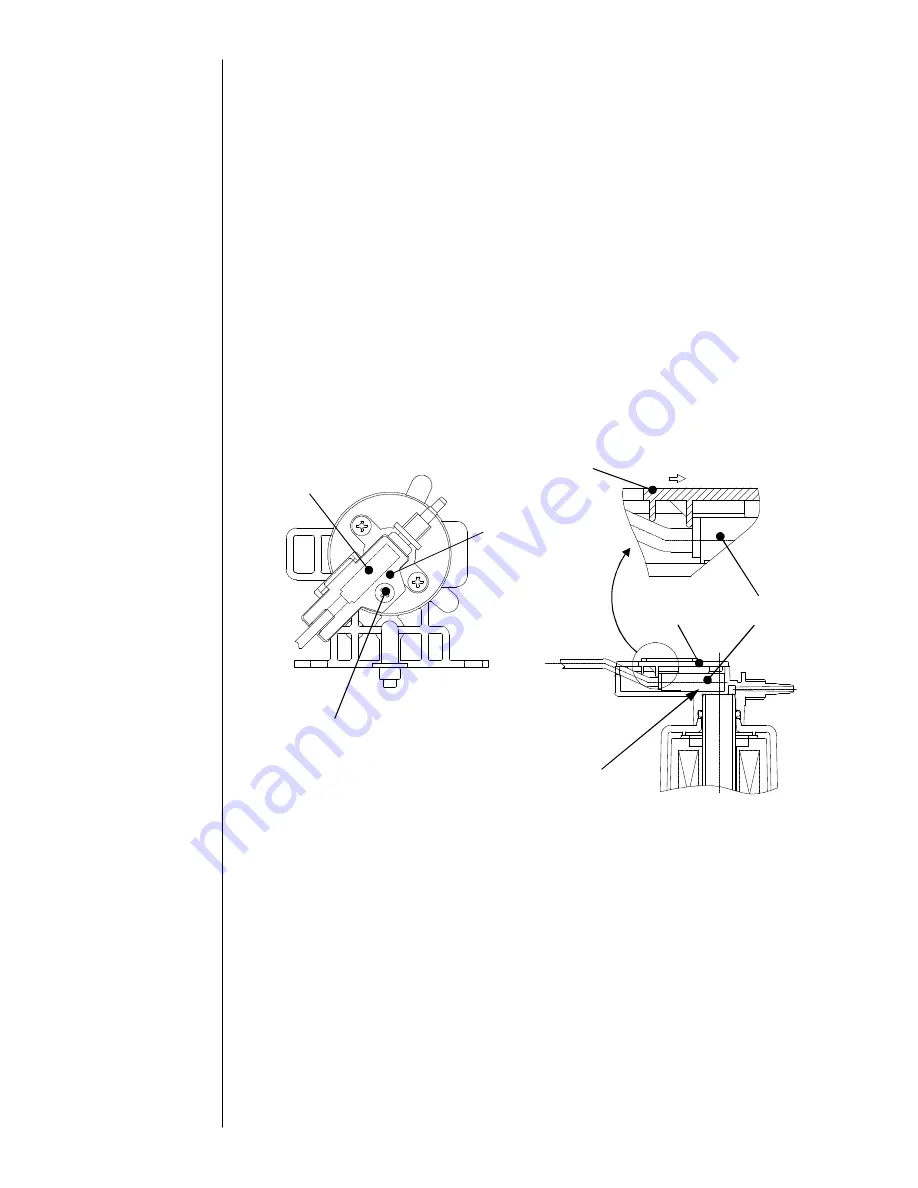

Cover setscrew

Cover

Proximity sensor

Model indication surface

Proximity sensor

Cover

Q

Tighten the screw

while pushing the

cover.

Cover

Summary of Contents for IJ PH

Page 1: ...Service Manual HITACHI Printer Model PH Revision Aug 2011 Version First edition ...

Page 2: ... Revision of PH service manual Revision Chapter Revised Page ...

Page 13: ...1 2 2 Main body internal PH D 1 8 ...

Page 80: ...3 25 3 25 Circuit diagram of EZJ95 ...

Page 201: ...7 1 7 Attached Drawing 7 1 Circulation System Diagram ...

Page 202: ...7 2 7 2 Electrical Connection Diagram ...

Page 205: ...7 5 7 4 Dimensions around charge electrode and deflection electrode Nozzle diameter 65 um ...