61

Chemical washing

You are recommended to chemically wash the plate heat exchanger after every 3 years of operation.

Refrigerant gas content

The Heat pumps are filled with R

32

refrigerant gas and tested in the factory. In normal conditions, there should be

no need for the Technical Assistance Service to intervene to check the refrigerant gas. However, over time, small

leaks may develop at the joints leading to loss of refrigerant and draining of the circuit, causing the unit to function

poorly. In this case, the leaks of refrigerant must be identified and repaired and the refrigerant circuit refilled.

Proceed as follows:

-Empty and dry the entire refrigerant circuit using a vacuum pump connected to the low and high pressure tap until

the vacuum meter reads about 10Pa. Wait a couple of minutes and check that this value does not rise to more than

200Pa.

-Connect the refrigerant gas cylinder or a filling cylinder to the low pressure line pressure gauge connection.

-Fill with the quantity of refrigerant gas indicated on the rating plate of the unit.

-Always check the superheating and sub cooling values. In the nominal operating conditions for the appliance,

these should be between 5 and 10°C and between 4 and 8°C respectively.

-After a couple of hours of operation, check that the liquid indicator indicates circuit dry (dry-green).

Important

In the event of partial leaks, the circuit must be completely emptied before being refilled

The R410a refrigerant must only be filled in the liquid state. Operating conditions other than nominal conditions may

produce considerably different values.

Seal testing or identification of leaks must only be carried out using R410a refrigerant gas, checking with a suitable

leak detector.

Prohibition

1.The ref

rigerant circuit must not be filled with a refrigerant other than that indicated of specification.

2.The use of a different refrigerant may cause serious damage to the compressor.

3.Oxygen, acetylene or other inflammable or poisonous gases must never be used in the refrigerant circuit as they

may cause explosion or poisoning.

4.Oils other than those indicated on manual before must not be used. The use of different oils may cause serious

damage to the compressor.

d)Shutting down for long periods

If it is previewed not to use the machine for long periods After deactivating the Heat pump:

-Make sure the model is in the power off model " ", or alternatively disconnect the unit from the power supply.

-Make sure the remote control switch is closed (if present) .

-Close the water valves.

Important

If there is a possibility that the outside temperature may drop below zero, there is the risk of freezing.

The water circuit MUST BE EMPTIED AND SHUT OFF POWER (when draining after heat pump operation take

care as the water may be hot) or antifreeze must be added in the proportion recommended by the manufacturer.

Summary of Contents for AU082FYCRA(HW)

Page 1: ...ATW Service Manual SYJS 03 2019REV A Edition 2019 03 ...

Page 11: ...9 405 410 600 174 174 450 950 965 395 6 Dimensions AU082FYCRA HW Unit mm ...

Page 12: ...10 AU112 162FYCRA HW Unit mm 1490 950 380 187 405 410 600 174 174 450 170 ...

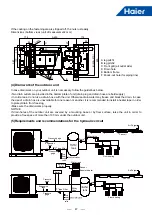

Page 13: ...11 AU082FYCRA HW 7 Piping Diagram ...

Page 14: ...12 AU112 162FYCRA HW ...

Page 27: ...25 12 Water Pressure Drop ...

Page 28: ...26 ...